Mechanical Installation Manual (450, 525, 600)

11.6. Fair in Excess Glue

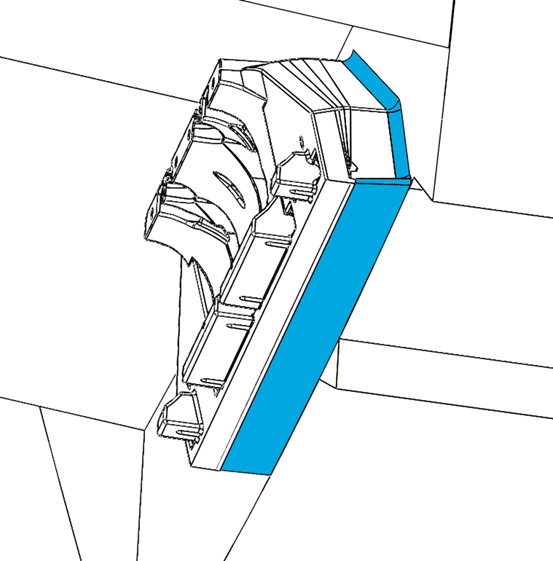

- Using a squeegee, putty knife, or tongue depressor, fill in the gap between the running surface of the hull and the Actuator Plate with excess adhesive, as shown below. Apply extra adhesive as needed. Note: The smooth transition from the hull bottom to the Seal Plate is critical for achieving the best performance out of the system.

- Using a squeegee, putty knife, or tongue depressor, clean away excess adhesive.

ATTENTION: For concealed cable entry, clean out all of the adhesive from around the Cable Gland. You must make sure the Cable Gland will be accessible after the adhesive cures.

- Make a smooth transition with adhesive on the upper edges of the Transom Plate to the transom. Apply extra adhesive as needed.

- Remove the masking tape from the Wedge Pack Assembly and transom. If needed, clean any excess adhesive using acetone or denatured alcohol and plain white paper towels.

- After fairing, check that the drain hole has remained clear. See Figure 53.

- Allow adhesive to cure before proceeding. Some adhesives have ‘handling times’ where the product feels firm but is not ready for loading. Some adhesives also have required times before submersion. Please follow the adhesive manufacturer’s instructions.

- For aluminum hulls, upon completion of the installation use a paint or similar coatings to protect the edges of aluminum from corrosion seeping between the approved two-part adhesive and aluminum.