Seakeeper 5 / 6 Installation Manual (90402-5) 6/5-233-5847 to Current

2.5.2 Preparation of Hull Structure

Refer to Seakeeper Drawing No. 90399 – Seakeeper 5/6 Bond-In Installation Details. Important dimensional and load information is given in this drawing that will impact the design details of the structure that will receive the Seakeeper as well as selection of the adhesive to bond the Seakeeper into the hull.

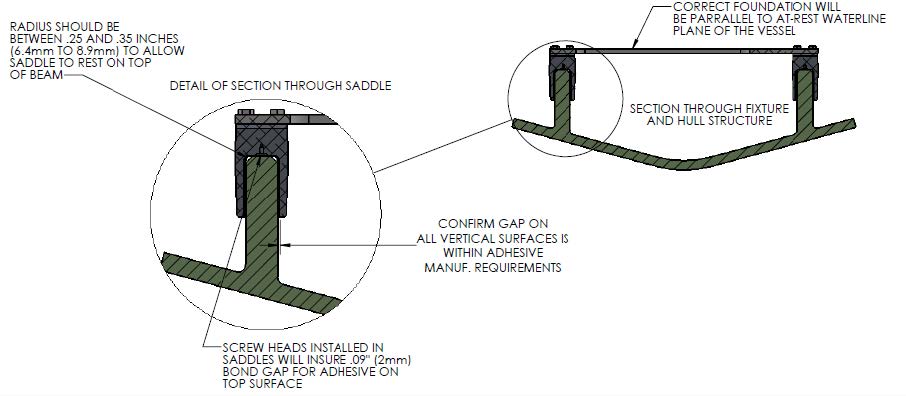

The foundation “saddles” of the Seakeeper are designed to be bonded directly to the composite hull structure of the vessel to effectively distribute gyroscopic loads. Complete coverage of the saddles and the hull structure surfaces is required for bond-in installations. Seakeeper recommends having a minimum of 1.6 L / 0.41 gal of adhesive, on hand for installation. Number of cartridges required is determined by dividing total volume by cartridge volume. Some adhesives require etching primer for aluminum surfaces (Plexus MA590 requires PC120 primer). Both manual and pneumatic application guns are available from adhesive manufacturers. Two workers should apply the adhesive at the same time to finish the installation before the adhesive starts to cure. To aid in determining the quantity of adhesive required, the interior surface area (bonding surfaces) of each saddle is 58.2 in.2 (375 cm2) for a total bonded surface area for all four saddles of 232.5 in.2 (1500 cm2).

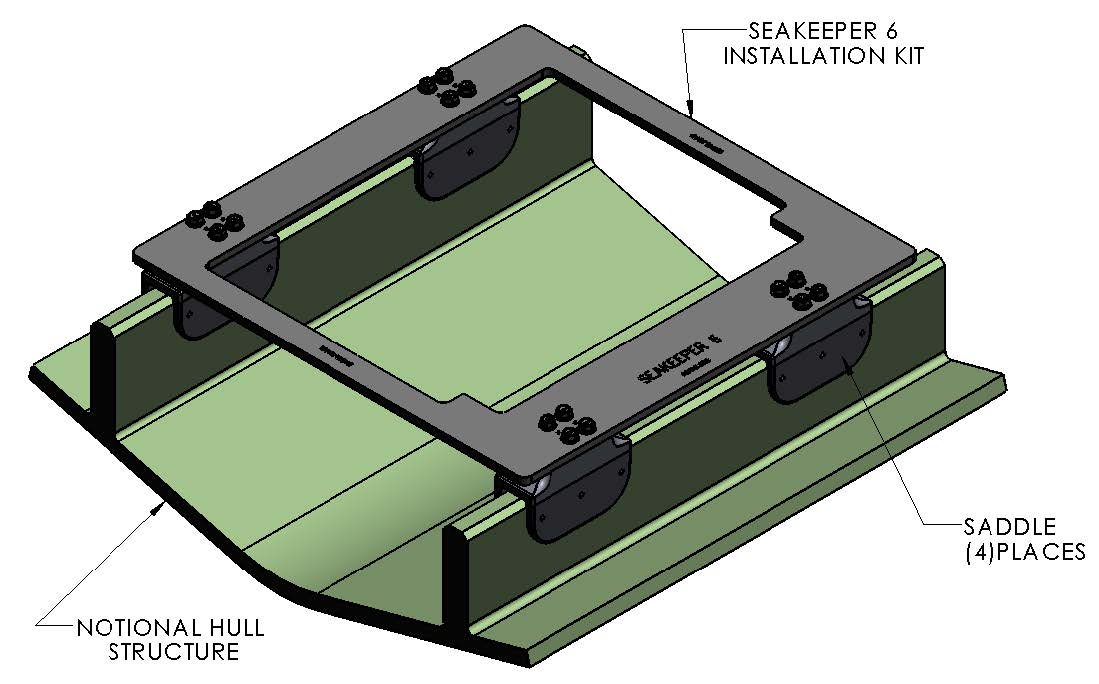

The hull structure supporting the Seakeeper should be installed so the Seakeeper is parallel to the waterline. The four areas on top of the beams that the saddles will bond to need to be co-planar within .13 in. (3 mm) for consistent adhesive bond gap. In addition, the four areas on top of the saddles on which the feet of the Seakeeper foundation will rest need to be co-planar within .06 in. (1.5 mm) to minimize potential distortion of Seakeeper support frame when installed.

Note that any paint or gel-coat present in bond area should be removed so that adhesive will bond directly to laminate fibers and resin. Fiberglass and aluminum surfaces should be sanded in a cross-hatch pattern with 80 grit sandpaper and thoroughly cleaned prior to adhesive application.

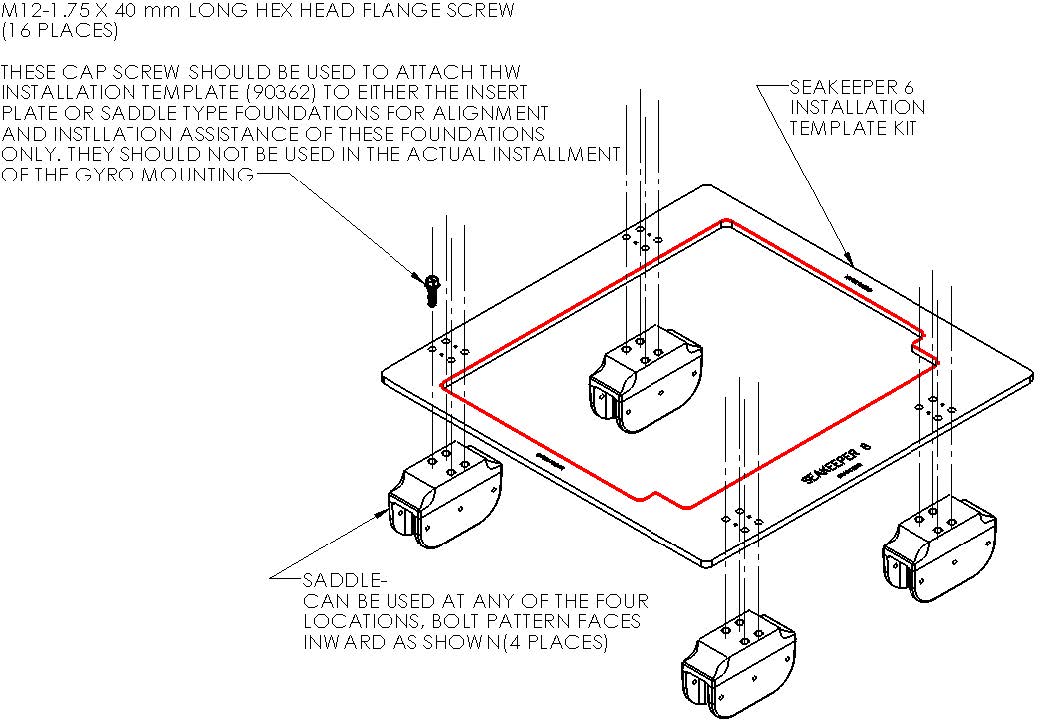

Seakeeper provides an installation fixture template, P/N 90392, that locates the saddles at the proper spacing both in the forward-aft direction and the port-starboard direction. See Figures 13 & 14 below. Once assembled with the provided saddle fittings, the fixture can be used to check saddle clearances and alignment of the hull structure. The fixture will allow the builder / installer to lay-up and adjust the foundation dimensions to create a low-clearance fit between the Seakeeper foundation saddles and the hull structure. Shear strength of the adhesive will be maximized if the cured thickness between the vessel structure and Seakeeper saddles is at the thinner end of the adhesive manufacturer’s recommended range. Therefore, the fixture should be used to confirm that the overall dimensions of the foundations are square and level and that the adhesive gap is within Seakeeper’s maximum recommended thickness of .13 in. or 3 mm.

Note: Do NOT use the installation fixture to establish Seakeeper envelope dimensions. Refer to Drawing No. 90399 – Seakeeper 5/6 Bond-In Installation Details, for envelope dimensions. A 3-D model of the Seakeeper is available on the Seakeeper website (www.seakeeper.com) to aid in designing the Seakeeper foundation and the space around the Seakeeper.

NOTE: MAKE SURE NO OBSTRUCTIONS FROM THE HULL STRUCTURE CAN BE SEEN WITHIN THE INSIDE OF THE INSTALLATION TEMPLATE KIT (INSIDE THE MARKED RED LINES). SEE DRAWING NO. 90399 – SEAKEEPER 5/6 BOND-IN INSTALLATION DETAILS.