Seakeeper 2 Installation Manual (90488-4); S/N 2-232-1564 to Current

4.3 Connecting Seawater to Heat Exchanger

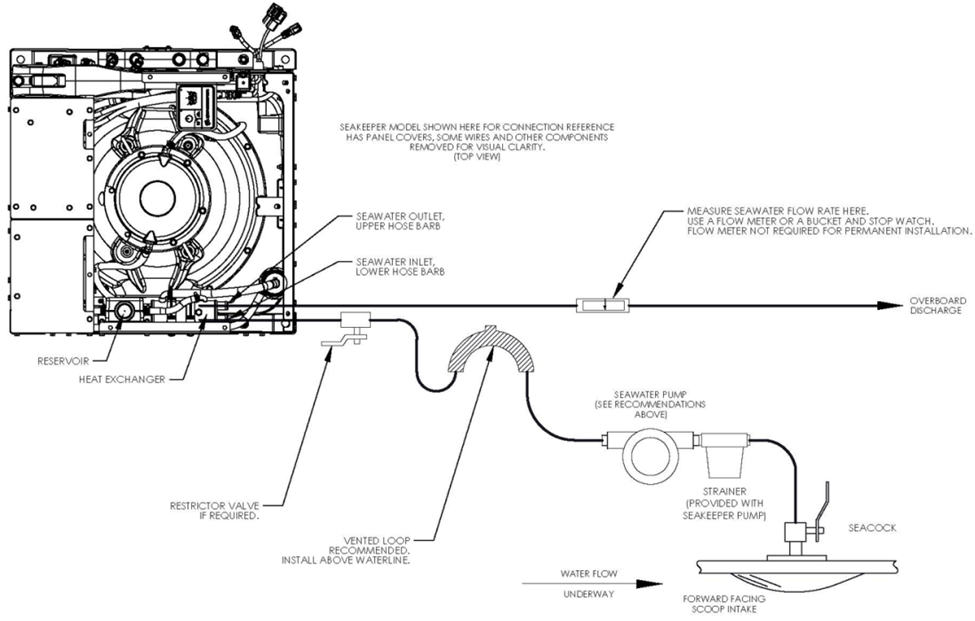

Refer to Figure 25 for typical seawater plumbing arrangement.

- Connect seawater pump to Seakeeper dedicated through-hull fitting. A strainer and seacock valve should generally be installed between the seawater inlet and the pump.

- Connect seawater from the installer-supplied pump to the lower 3/4 in. (19 mm) hose barb on the heat exchanger. Use the same practices as for other below-waterline seawater plumbing.

- Connect seawater discharge to the overboard drain. Use the same practices as other seawater plumbing below the waterline.

- The required flow rate is 2 GPM (7.6 LPM) minimum and 6 GPM (22.7 LPM) maximum.

- In addition to initial operation at the dock, new Seakeeper installations should be checked for a minimum 2 GPM (7.6 LPM) flow while the vessel is at speed and when backing down.

- If no other method of confirming flow is available, the discharge line may be temporarily diverted to a bucket. Flow is calculated from time to fill a known volume.

- Flowrates in excess of 6 GPM (22.7 LPM) could affect heat exchanger life.

- Inspect raw water plumbing during sea trial for any signs of leakage.