Seakeeper Ride | Electrical Installation Manual

8. Wiring and Terminating Cables

Wiring Introduction

WARNING! Seakeeper Ride is critically dependent on these steps for the system to operate as intended. The installer must review the electrical drawings in Section 3 before terminating wiring. INCORRECT WIRING MAY RESULT IN DESTRUCTION OF EQUIPMENT, DAMAGE TO THE BOAT OR OTHER PROPERTY, SERIOUS INJURY OR DEATH.

8.1. Seakeeper Ride Proprietary CAN Bus

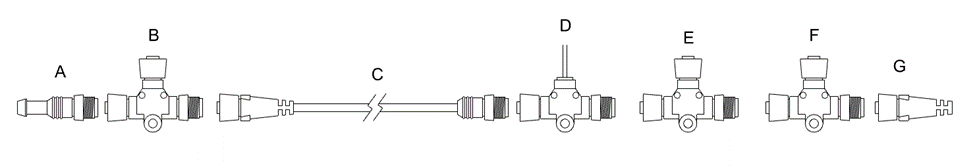

Seakeeper Ride requires two (2) CAN Bus Tees, one (1) CAN Bus Powered Tee, one (1) NMEA 2000 Cable, one (1) Male CAN Bus Terminator, and one (1) Female CAN Bus Terminator. A third CAN Bus Tee will be provided with the optional Keypad sold separately. These components together form the Seakeeper Ride Proprietary CAN Bus and provide communication across the system. Each component must be installed correctly for Seakeeper Ride to function.

A. Male Terminator

B. Tee to Distribution Module

C. 10 m (32.8 ft) Cable to Distribution Module

D. Powered Tee

E. Tee to Keypad (Optional)

F. Tee to Software Module

G. Female Terminator

Figure 11 – Seakeeper CAN Bus Tees and Terminators

CAN Bus Tees and Cable

The CAN Bus Tees (B, E, and F in Figure 11) are connection points for the major electronic components of the Seakeeper Ride system. The 10 m (32.8 ft) NMEA 2000 Cable (C in Figure 11) allows the CAN Bus to run to the stern of the boat where the Distribution Module is located. The supplied Phillips No. 6 x 1.25 in. screws are for mounting the CAN Bus Tees to the boat.

Powered CAN Bus Tee

The Powered Tee (D in Figure 11) is responsible for providing power to the proprietary CAN Bus.

The black wire should be grounded.

The red wire should be connected to a 12 V power source, which may be through the boat’s key switch or a battery isolation switch. Note that this power must be able to be cycled off and on during setup and diagnostic procedures.

Ensure the 3A inline fuse between the Key and Power Tee is not removed during installation.

WARNING! Do not reverse the polarity of the CAN Bus Tees. INCORRECT WIRING, SUCH AS THIS, MAY RESULT IN DESTRUCTION OF EQUIPMENT, DAMAGE TO THE BOAT OR OTHER PROPERTY, SERIOUS INJURY OR DEATH.

CAN Bus Terminators

On one end of the Seakeeper Ride Proprietary CAN Bus, install a Male Terminator, and on the opposite end, install a Female Terminator (A and G in Figure 11).

One CAN Bus Terminator must be installed within three (3) feet of the Software Module. One CAN Bus Terminator must be installed within three (3) feet of the Distribution Module. The result of this CAN Bus configuration is a long cable from the Tee chain (D, E & F in Figure 11) in the console to the final Tee in the aft end of the boat near the Distribution Module. This configuration builds a stable network.

8.2. Software Module Wiring

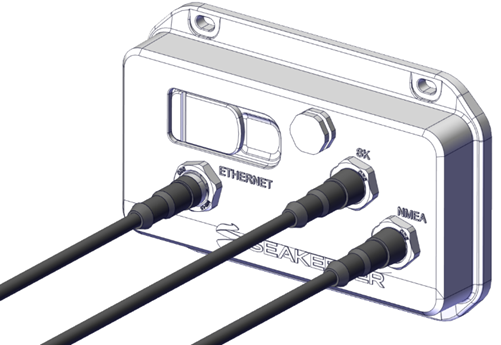

Seakeeper Ride Proprietary CAN Bus Cable

Connect a NMEA 2000 cable between the Software Module attachment point labeled “SK,” and the Seakeeper CAN Bus Tee (F in Figure 11). The 3.3 ft (1 m) cable supplied is recommended.

On the male end of this CAN Bus Tee, attach a Female Terminator (G in Figure 11).

Seakeeper Proprietary CAN Bus negative wire will need Clean Ground because, it cannot go through the engine manufacturers wiring harness or it will lose power when engine is started.

NMEA 2000 Network

From the side of the Software Module labeled “NMEA,” attach a NMEA 2000 cable to the boat’s NMEA 2000 Network Backbone. The 19.7 ft (6 m) cable supplied is recommended.

This may require a new Tee added to the backbone (not included).

Be sure to follow NMEA Backbone protocol and observe Terminator and Tee requirements.

Ethernet Connection

From the port side of the Software Module labeled “Ethernet,” attach the Ethernet Adapter Cable that suits the boat’s Multifunction Display. This cable must be purchased separately from Seakeeper.

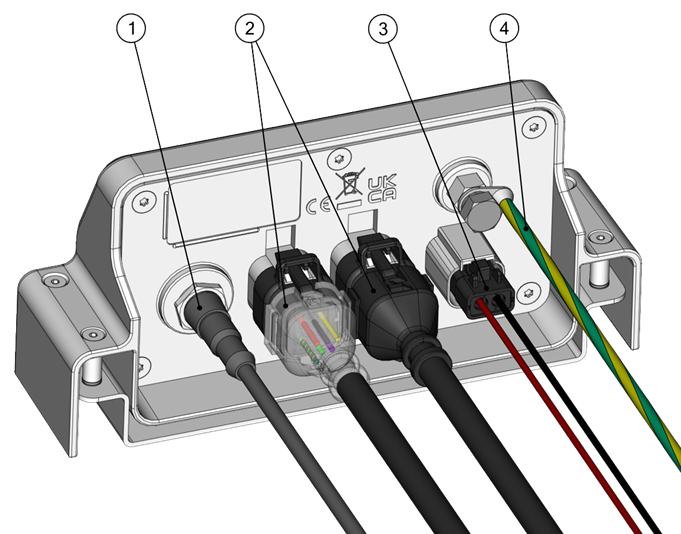

8.3. Distribution Module Wiring

- Seakeeper CAN Bus

- Controller Cables

- Power Cable

- Ground Wire

Seakeeper Ride Proprietary CAN Bus Cable

Connect one end of the supplied NMEA 2000 Cable to the Distribution Module. Connect the other end of the NMEA 2000 Cable to the CAN Bus Tee (B in Figure 11). The supplied 0.6 m (2 ft) Cable is recommended. Ensure a Male Terminator (A in Figure 11) is installed at the this end of the CAN Bus Tee.

Controller Cables

The Controllers arrive with a custom cable appropriate for installation in the most challenging areas of a boat. The cables are resistant to water, oil, and electromagnetic interference.

Note: This cable is not to be modified. Do not allow acetone to come in contact with the Controller Cable Gland Sealing Nut (Figure 56 in the Mechanical Installation Manual)

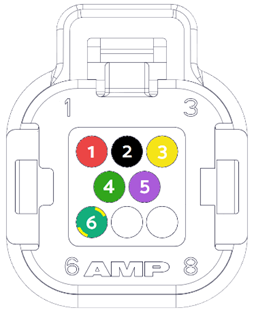

ATTENTION: When inserting cable end pins into the Ampseal Plug, please use caution. Damage to these pins will result in Actuator replacement.

The cable ends must be inserted into the Ampseal plug. Slide shrink wrap over the wire prior to inserting cable ends. Ensure the wedge lock on the Ampseal Plug Housing is open. Follow Drawing No. 90609 – Seakeeper Ride Cable Block Diagram and Figure 14 for specific color to pin number identification. Review these written instructions and this video from Ampseal for best practices. If ports 7 and 8 are accidentally pierced, be sure to insert Ampseal Cavity Sealing Plugs to prevent water from entering. Close the wedge lock by squeezing it firmly onto the Ampseal Plug Housing.

Once the pins are secured in the Ampseal plug, apply the heat shrink over the point where the cables meet the Ampseal plug. The plug is then ready to be attached to the Distribution Module. Do not connect the Controller Cables to the Distribution Module at this point. The cables will be connected during the commissioning procedure for proper programming and identification.

1. RED, +V (16 AWG)

2. BLACK, 0V (16 AWG)

3. YELLOW, CAN_HI (20 AWG)

4. GREEN, CAN-LO (20 AWG)

5. PURPLE, WAKE (20 AWG)

6. GREEN/YELLOW, GND (16 AWG)

(7 and 8 are left blank or have plugs if pierced.)

ATTENTION! The specific color to pin number identification is critical. Incorrect placement may result in destruction of the Actuator.

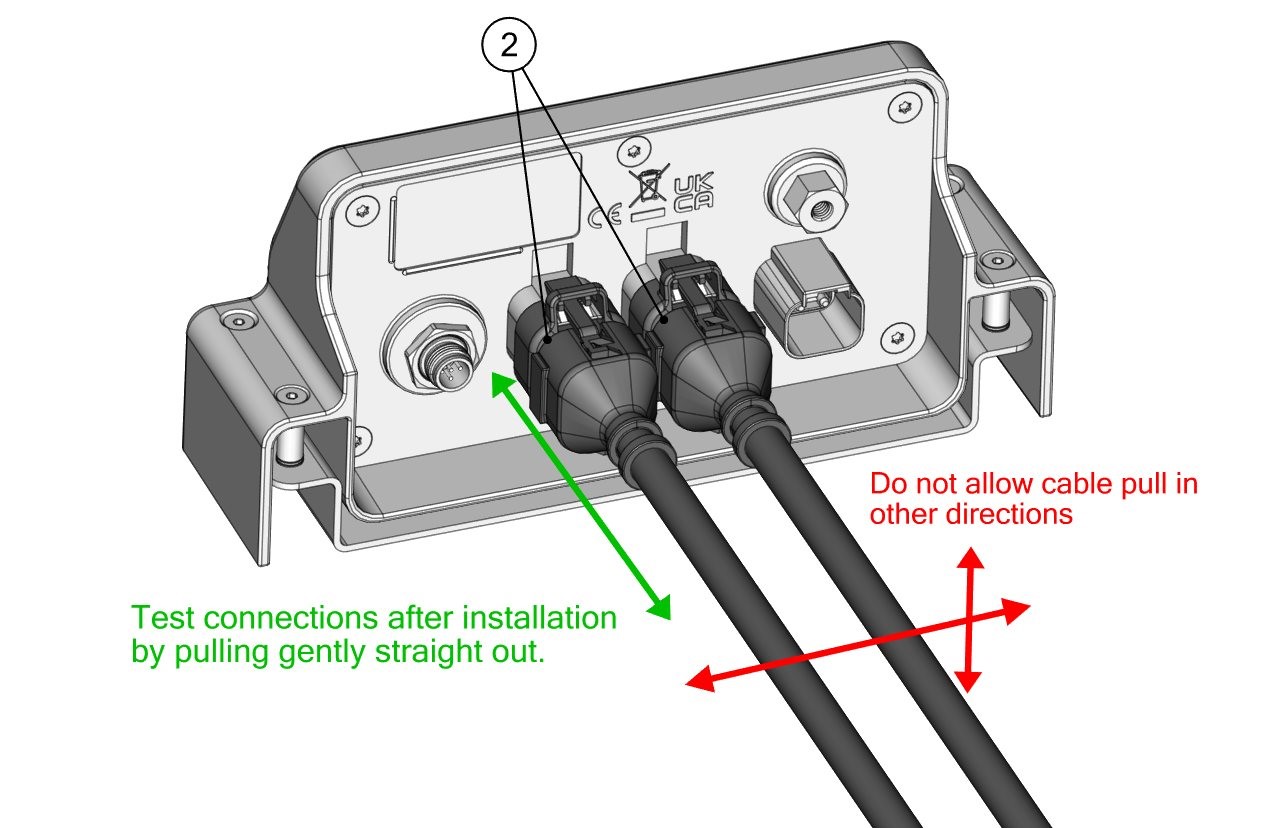

When connecting the Controller Cables during commissioning, test to make sure they are attached correctly. Controller Cables should click in and fit firmly once inserted. When Controller Cables are secured, gently pull straight out to ensure they do not come out. To ensure the cables remain properly attached, do not allow the cables to be pulled in any other direction at any time.

Ground Wire

The ground wire cable attaches the Distribution Module to the vessel’s common ground. Attach the loose eyelet of this cable to the common ground of the boat. The ground wire should be wired to bus bar going straight to the battery. Do not ground through another electrical system on the boat.

This cable must be 8 AWG or larger.

WARNING! Do not squeeze or crimp the cables too tightly or they could fail.

Power Cable

The power cable provides power to the Distribution Module so the Controllers can move as needed. The power cable is made up of two (2) 12 AWG wires, one red and one black.

The black wire is to be attached to the negative terminal of the vessel’s 12 V power, and the red wire is to be attached to a 25 A circuit breaker or fuse. The power to the circuit breaker or fuse is to be supplied by the vessel’s battery isolation switch and the positive side of 12 V power.

WARNING! Do not reverse the polarity of the Power Cable. INCORRECT WIRING, SUCH AS THIS, MAY RESULT IN DESTRUCTION OF EQUIPMENT, DAMAGE TO THE BOAT OR OTHER PROPERTY, SERIOUS INJURY OR DEATH.

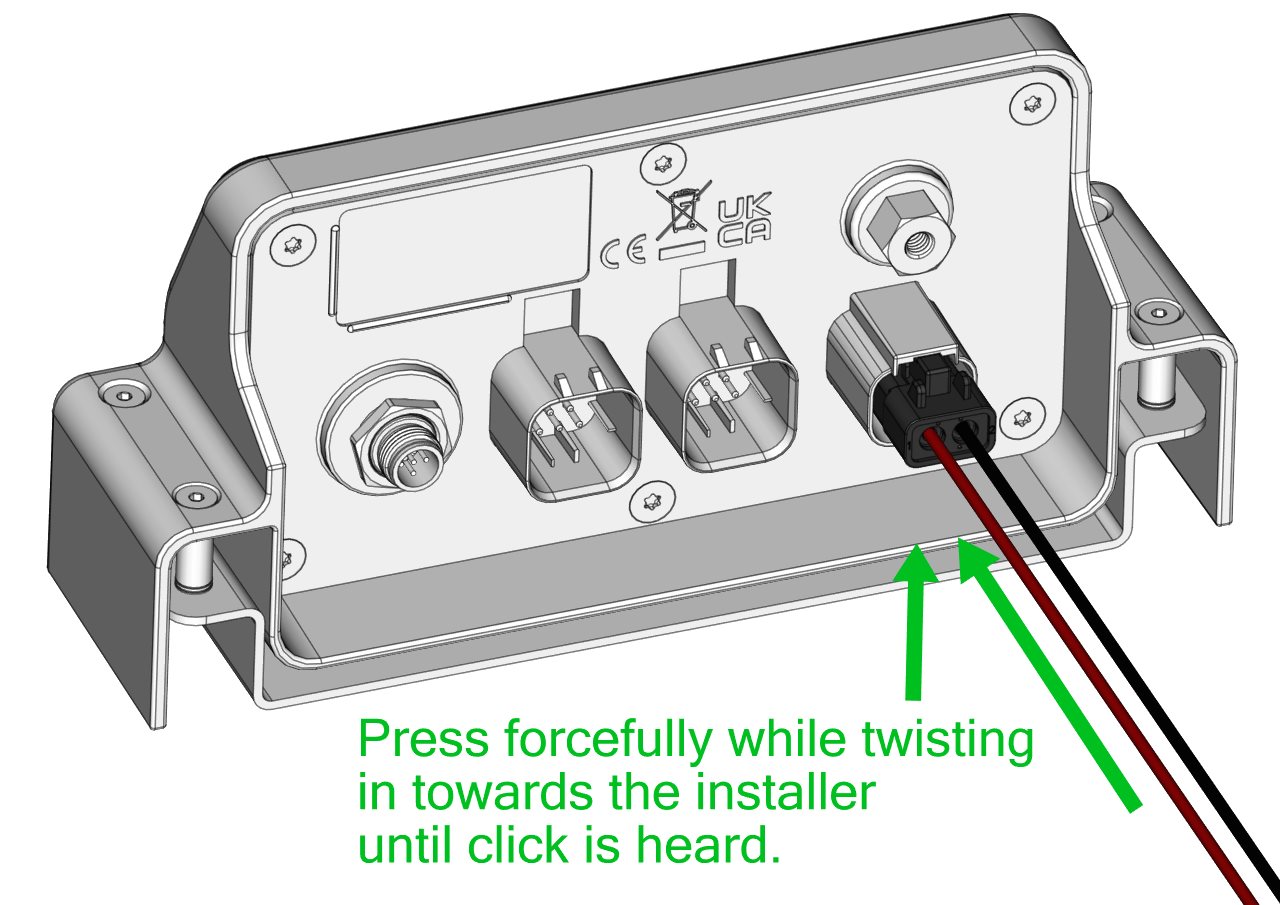

When connecting the power cable into the Distribution Module, press in forcefully while twisting in towards the installer until a small, audible clicking sound is heard. When the power cable is secured, gently pull straight out to ensure it does not come out.

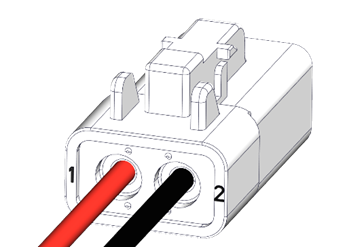

If the Power Cable is not used, choose a power cable that has at least 12 AWG wires to ensure sufficient power supply to the Actuators. Do not use a power cable longer than 10 m (32.8 ft), as the equipment is voltage-sensitive and current-sensitive. The power cable termination must be in a 2-pin Deutsch plug Part Number DTP06-2S with the red wire in terminal 1 and the black wire in terminal 2 as shown below. Review this video from Deutsch for best practices.

8.4. Keypad Wiring (Optional)

Connect a NMEA 2000 cable to the Keypad and Seakeeper Ride CAN Bus Tee (E in Figure 11) using the 3 m (6.6 ft) cable supplied.

You have now completed the electrical installation of the Seakeeper Ride system. Follow the instructions in the Seakeeper Ride Commission Instructions for the first start and calibration of the system.