Seakeeper 35 / 30HD Installation Manual (90268-7)

Selection of Installation Location

Selection of mounting location of the Seakeeper should consider the following desirable features:

The Seakeeper must be installed aft of amidships to minimize high acceleration loadings due to hull/wave impacts during operation at high speed or in large waves. If the only possible Seakeeper location is forward of amidships then the installer should have Seakeeper review the installation location prior to finalizing the design.

- Overhead access or sufficient clearance for removal / re-installation of the Seakeeper for overhaul in future years.

- The Seakeeper should be installed in a dry space to minimize effects of corrosion.

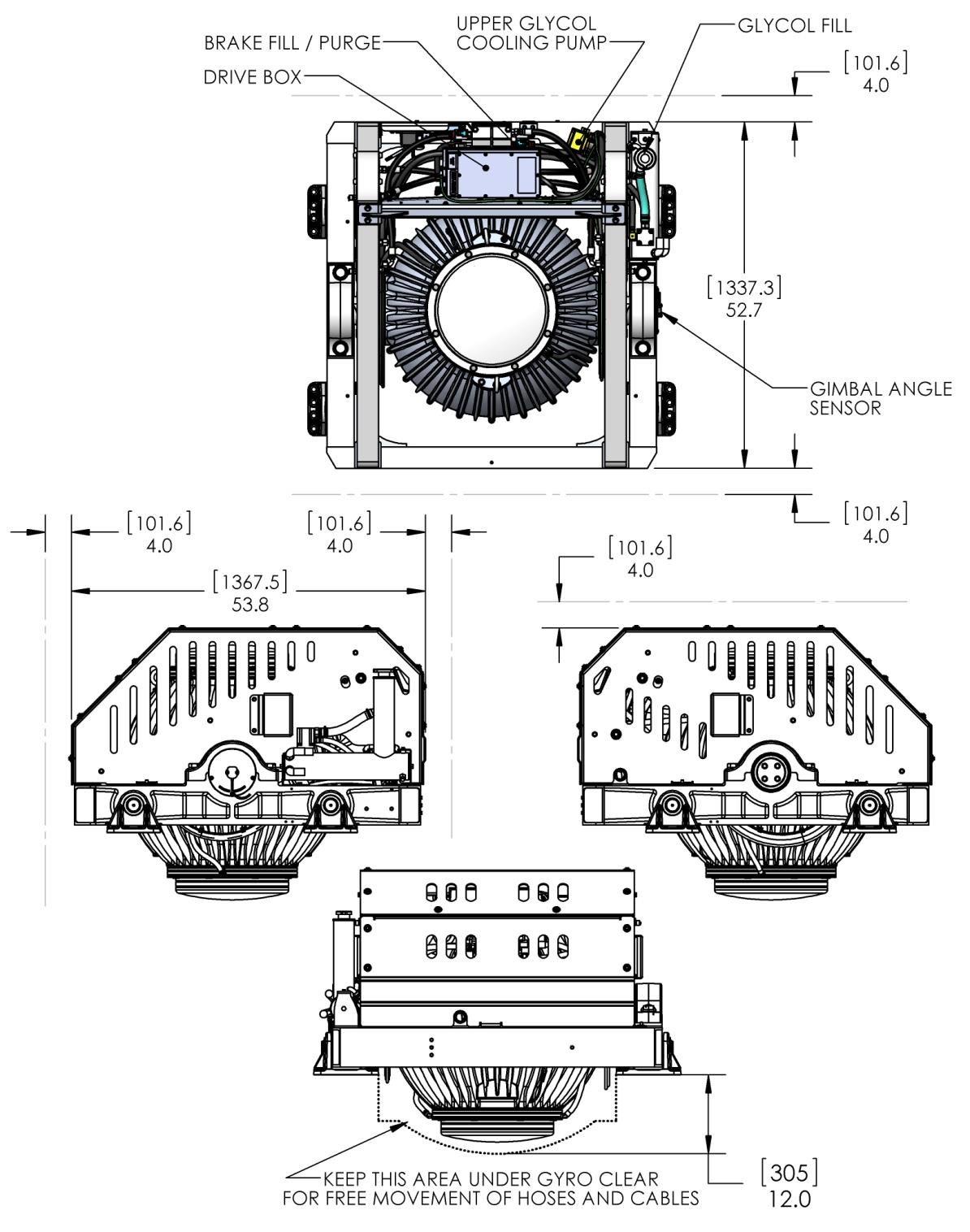

- Clearance for replacement of gimbal angle sensor on gimbal shaft (see Figure 2).

- Clearance for filling / purging brake hydraulic oil (see Figure 2).

- Clearance for filling water/glycol cooling circuit (see Figure 2).

- Clearance for replacement of brake hydraulic cylinders (see Figure 2).

VIEWS SHOWING RECOMMENDED CLEARANCES AROUND THE SEAKEEPER FOR USE OF HANDTOOLS, EASE OF MAINTENANCE, INSTALLATION, AND PROPER OPERATION.

Figure 2 – Seakeeper 35 Installed Clearance Considerations

Safety

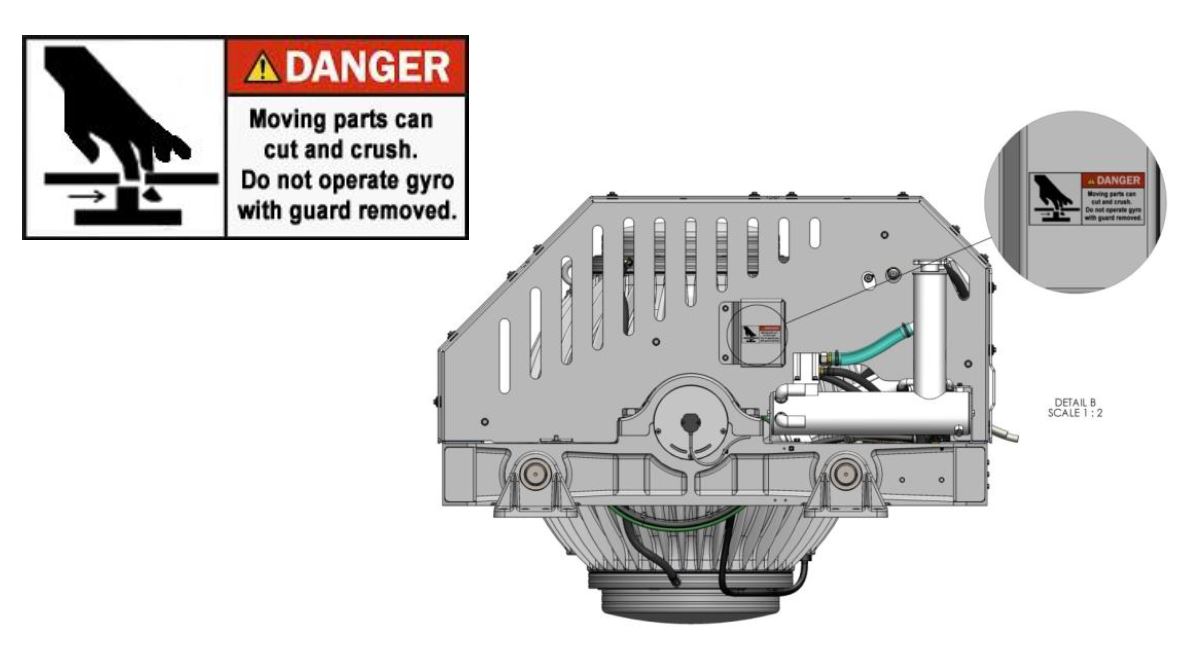

There is a large torque about the gimbal axis when the Seakeeper is precessing. Seakeeper cover panels are provided to prevent personnel or equipment from contacting the Seakeeper while it is in operation. These covers should not be stepped on or have anything placed on top. The covers should always be in place during operation. The cover side panels contain safety shields as shown below. Do not operate the Seakeeper without these safety shields in place.

If it is ever necessary to access the Seakeeper while the flywheel is spinning, the Seakeeper must be locked at the display to stop the Seakeeper from precessing. Seakeeper regular scheduled maintenance should not be attempted unless the Seakeeper is locked and the flywheel has stopped spinning. The Seakeeper should be treated with the same respect one gives a high speed rotating propeller shaft or engine shaft.

Noise/Soundproofing

Seakeeper noise has been measured under steady state conditions (no wave load) in Seakeeper‘s Engineering Lab and in our Factory Demo Boat. The steady state noise is typically in the range of 70-75 dB un-weighted. As the frequencies emitting the highest sound pressures are low (like other marine machinery), it is recommended that the Seakeeper be installed in a machinery space that is already treated with soundproofing.