Seakeeper 35 / 30HD Installation Manual (90268-7)

Saddle Installation

Saddle Installation Introduction

Seakeeper recommends a slow curing, non-sagging structural adhesive for bonding the saddles to the GRP hull structure. Such an adhesive is Plexus MA590 which is a two-part methacrylate adhesive. Details of the bonding procedure in this manual will involve the Plexus MA590 product, but that should not exclude other suitable adhesives the installer chooses to use. See Sheet 6 of Seakeeper Drawing No. 90255 – Seakeeper 35/30HD Bond-In Installation Details for loads information and recommended adhesive properties.

Check and Preparation of Hull Structure

Refer to Seakeeper Drawing No. 90255 – Seakeeper 35/30HD Bond-In Installation Details. Important dimensional and load information is given in this drawing that will impact the design details of the structure that will receive the Seakeeper as well as selection of the adhesive to bond the Seakeeper into the hull.

The foundation “saddles” of the Seakeeper are designed to be bonded directly to the composite hull structure of the vessel to effectively distribute Seakeeper loads. A complete bond is required between the inside surface of the saddles and the hull structure. An estimate of adhesive volume required should be calculated for each installation based on gaps between saddles and structural members. There is some adhesive waste as a part of the process so a good rule of thumb is to purchase 50% more adhesive than estimated volume to ensure a complete bond. Depending on conditions and adhesive used, two workers may be required to apply the adhesive at the same time to finish the installation before the adhesive starts to cure. To aid in determining the quantity of adhesive required, the interior surface area (bonding surfaces) of each saddle is 325 in.2 (2,097 cm2) for a total bonded surface area for all four saddles of 1,300 in.2 (8,387 cm2).

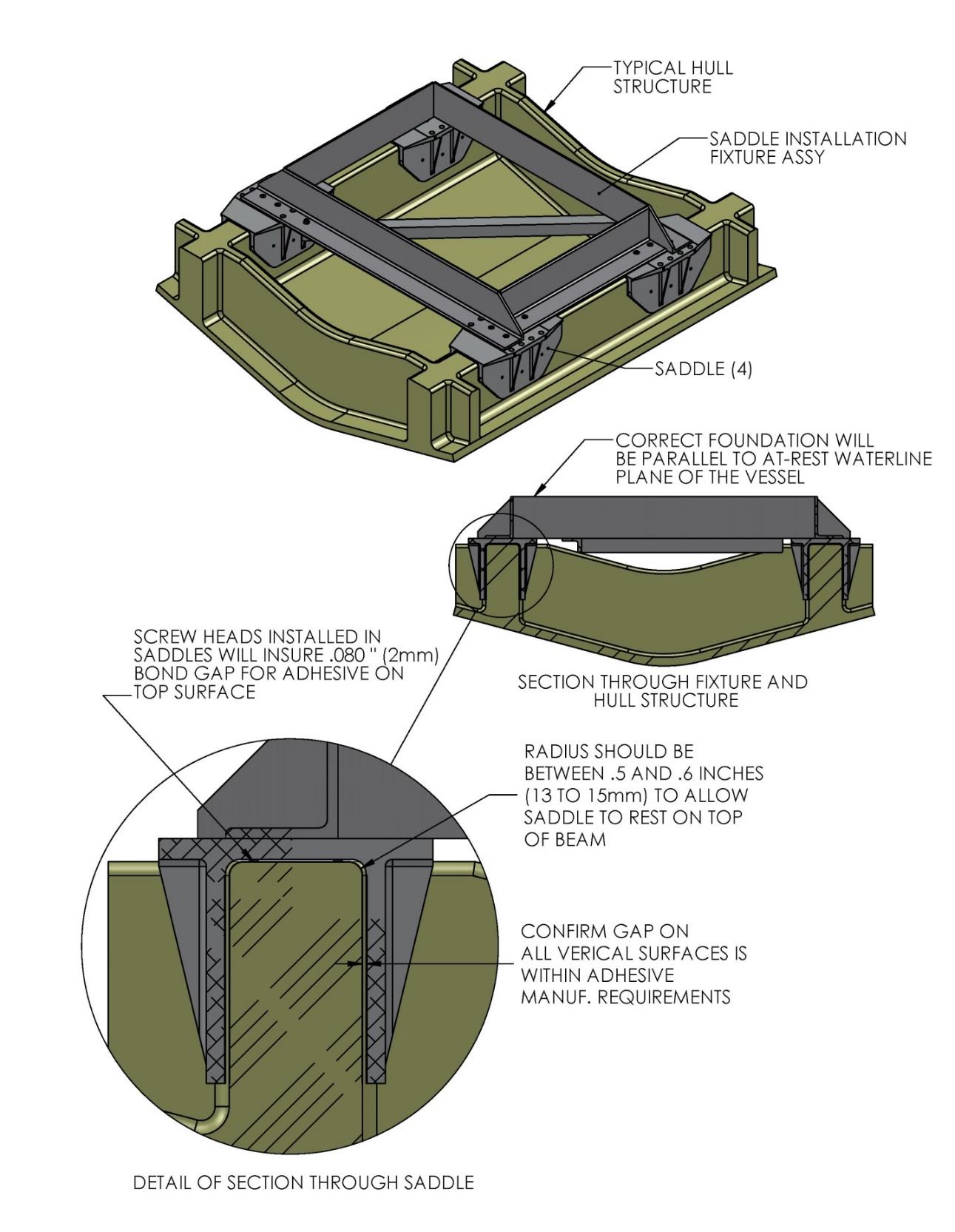

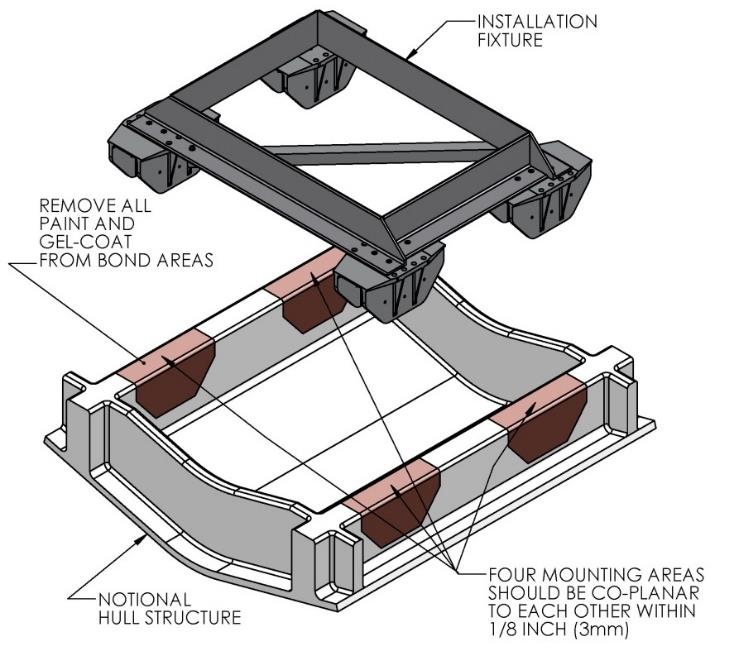

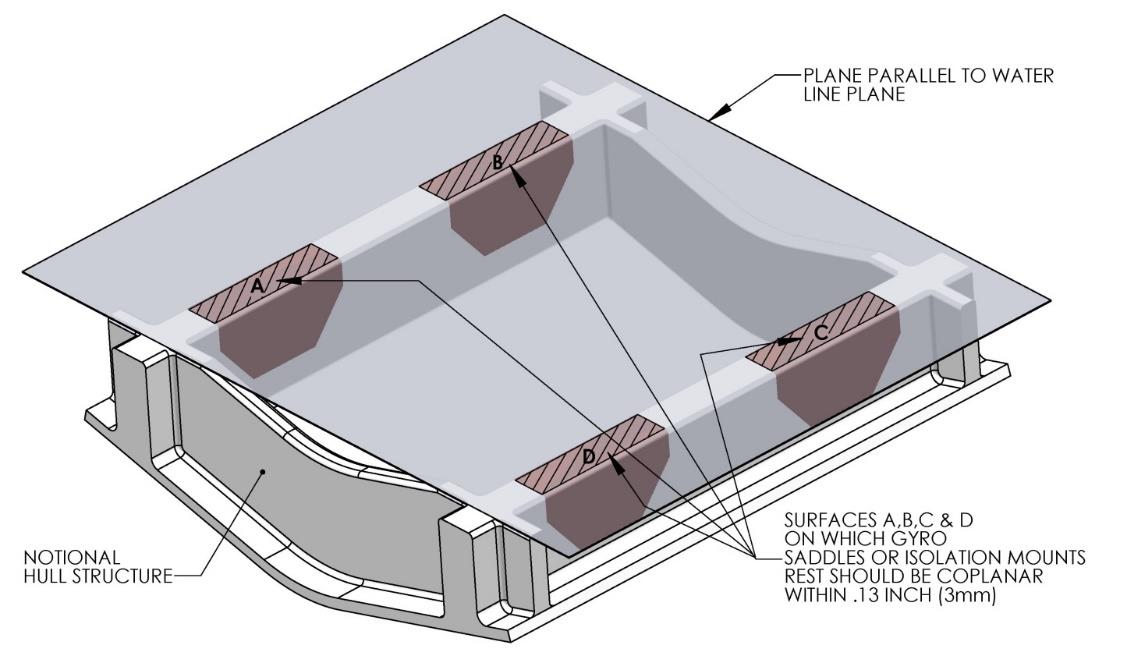

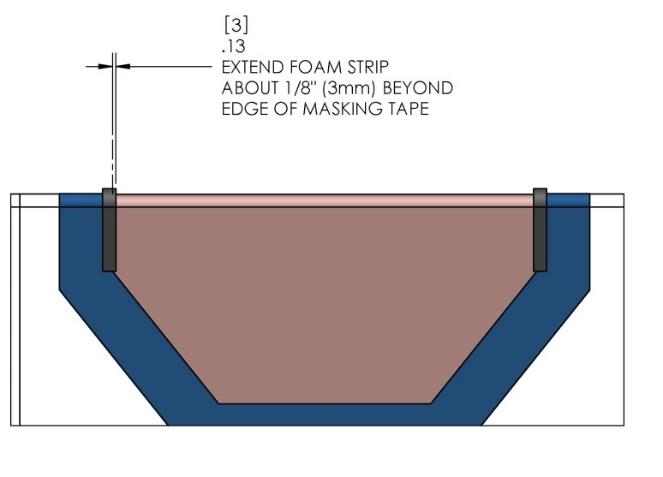

The hull structure supporting the Seakeeper should be arranged so the Seakeeper is parallel to the waterline. In addition, the four areas on top of the beams that the saddles will bond to need to be co-planar within .13 in. (3 mm) to minimize potential distortion of Seakeeper support frame when installed, as shown in Figure 12.

Note that any paint or gel-coat present in bond area should be removed so that adhesive will bond directly to laminate fibers and resin.

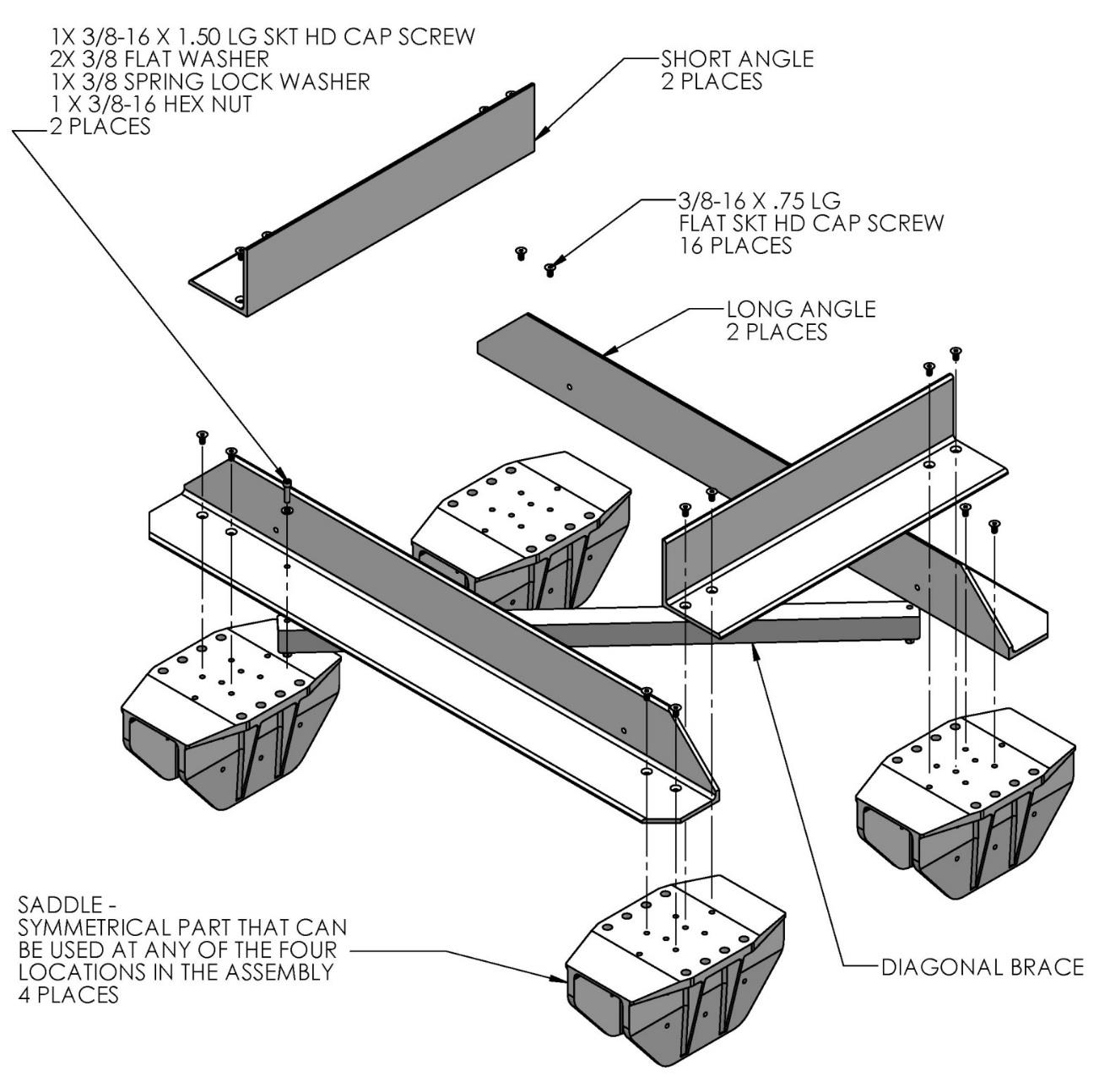

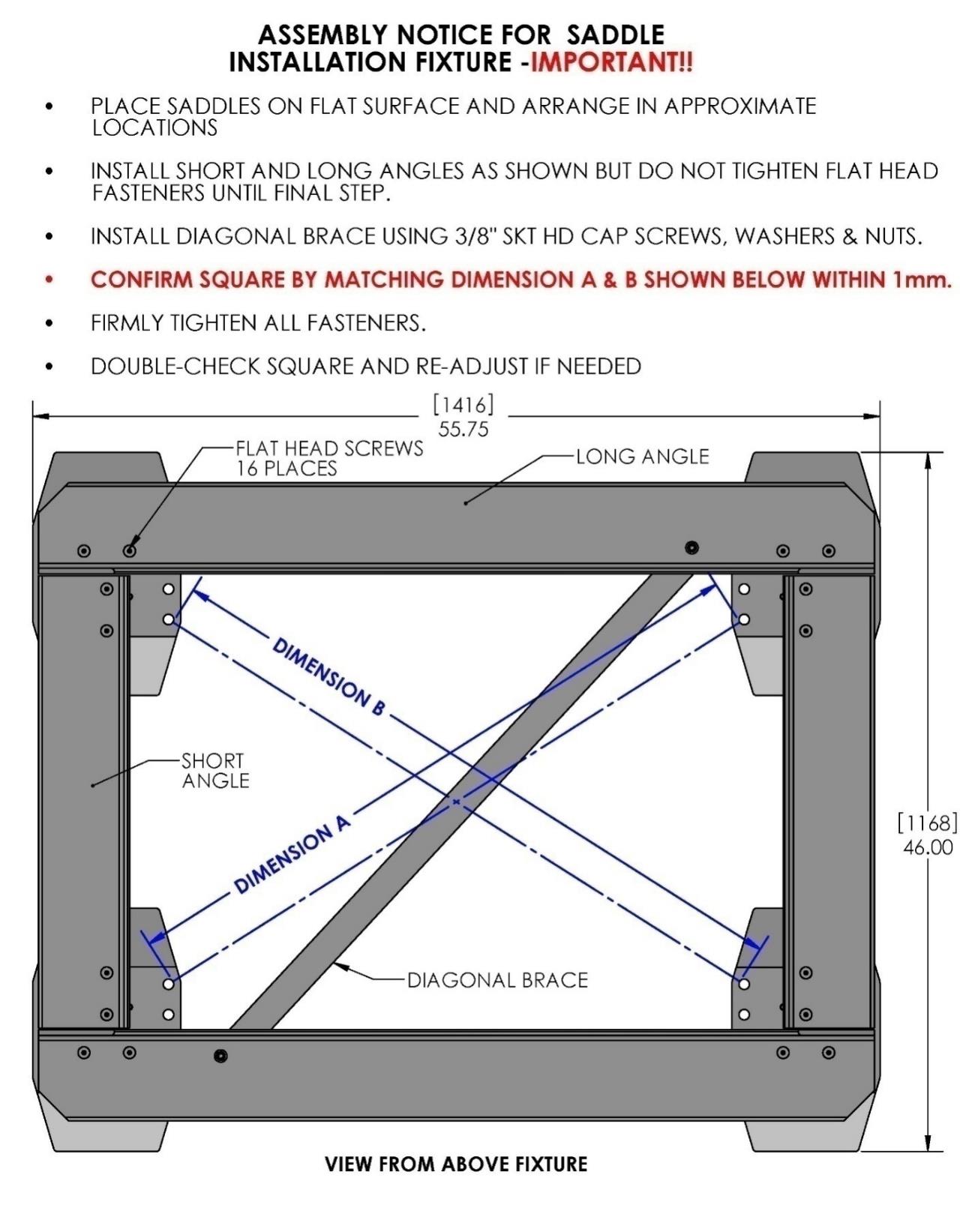

Seakeeper provides an installation fixture template (P/N 90088), that locates the saddles at the proper spacing both in the forward-aft direction and the port-starboard direction. See Figures 7, 8 & 9 below. Once assembled with the provided saddle fittings, the fixture can be used to check clearances and alignment of the hull structure. The fixture will allow the builder / installer to lay-up and adjust the foundation dimensions to create a low-clearance fit between the Seakeeper foundation saddles and the hull structure. Shear strength of the adhesive will be maximized if the cured thickness between the vessel structure and the Seakeeper saddles is at the thinner end of the adhesive manufacturer’s recommended range. Therefore, the fixture should be used to confirm that the overall dimensions of the foundations are square and level and that the adhesive gap is within Seakeeper’s recommended range of .04 in. to .13 in. (1 to 3 mm).

Note: Do NOT use the installation fixture to establish Seakeeper envelope dimensions. Refer to Drawing No. 90255 – Seakeeper 35/30HD Bond-In Installation Details, for envelope dimensions. A 3-D model of the Seakeeper is available on the Seakeeper website (www.seakeeper.com) to aid in designing the Seakeeper foundation and the space around the Seakeeper.

Fiberglass Hull Preparation

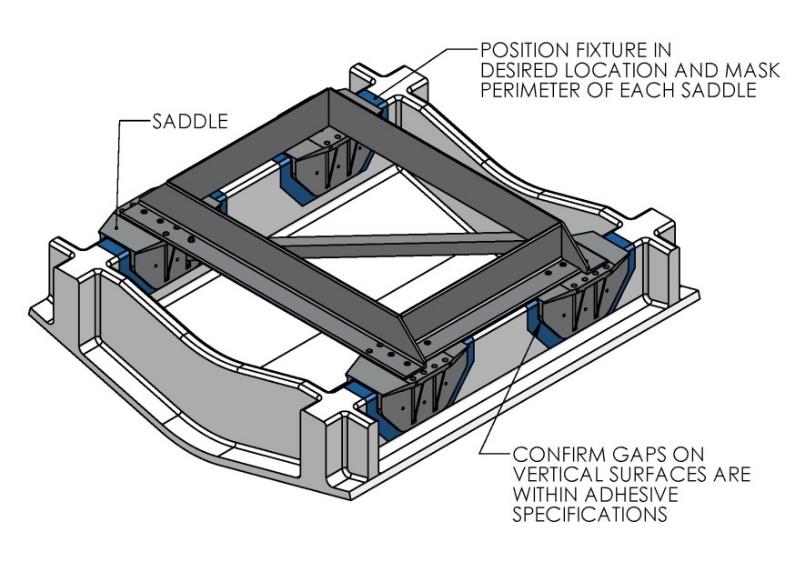

- Position installation fixture (Figure 10) on hull girders noting recommended clearances for maintenance from Figure 2 (in Section: Selection of Installation Location). Check that the screws fastening the saddles to the installation fixture are tight (Figure 8).

- Mask hull area (as shown in blue, Figure 11) around foundation saddles for easy clean-up and to create an outline of surface area to receive adhesive, as shown in brown (Figure 10). Ensure that the bond gap is within adhesive manufacturer’s recommended thickness, or 3 mm if using Plexus MA590.

- Raise fixture clear of foundation. Check all four mounting areas are co-planar to within .13 in. (3 mm) to each other, as well as parallel to the water line plane, as shown in Figure 12.

- Thoroughly clean with alcohol or acetone all areas (highlighted in brown, Figure 10) of girders to be bonded to remove any contaminates. Use new paper towels for cleaning, not shop rags.

- Remove any paint or gel-coat from bond surfaces so that adhesive will bond directly to laminate fibers and resin.

- Thoroughly sand girder bond surfaces with 80 grit sandpaper. (IMPORTANT – BOND STRENGTH MAY BE REDUCED IF THIS STEP IS SKIPPED.)

- Wipe surfaces clean from dust with alcohol or acetone using new paper towels, not shop rags.

- Re-position installation fixture on girders and double-check that the adhesive gap is within the adhesive manufacturer’s maximum recommended thickness. Seakeeper recommends a maximum gap of 3 mm if using Plexus MA590.

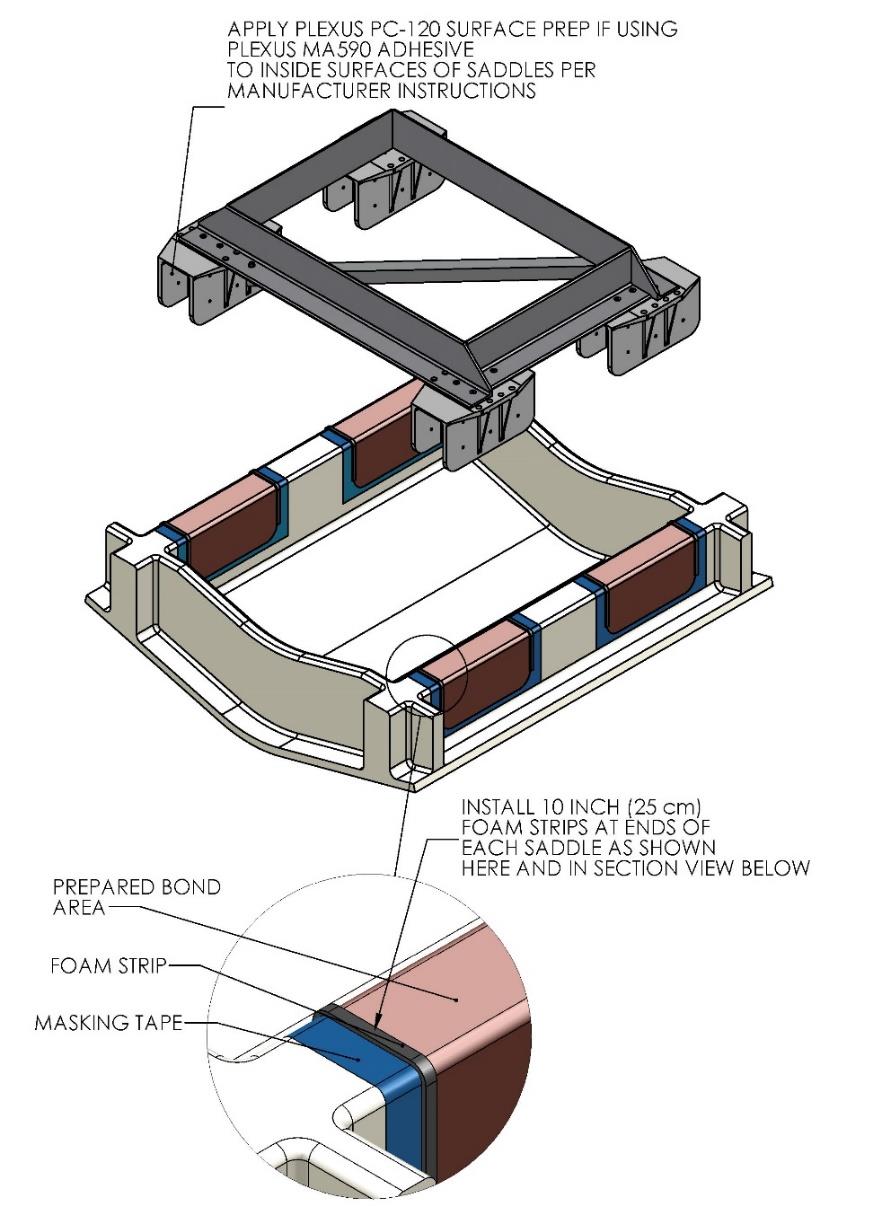

- Lift installation fixture clear of foundation. Apply Seakeeper provided adhesive backed foam strips at the eight locations shown (each end of four saddles) in Figure 13 below. These strips are to serve as a dam to minimize adhesive escaping out the ends of the saddles as they are positioned over the bond area.

Note: If bonding saddles to a metal structure, contact Seakeeper for hull preparation instructions.

Seakeeper Saddle Preparation

- Ensure that screws fastening saddles to the installation fixture are tight.

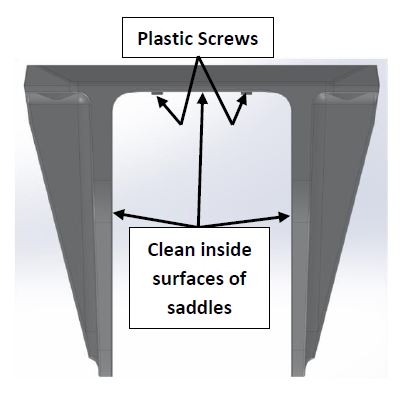

- Check that each saddle contains 4 plastic screws which will ensure an adhesive gap of .080 in. (2 mm) on top surface of hull as shown in Figure 14. Do not remove these screws.

- Thoroughly clean with alcohol or acetone the inside surfaces of Seakeeper foundation saddles to remove any contaminates as shown in Figure 14. Use new paper towels for cleaning, not shop rags.

- Thoroughly sand all saddle inside surfaces with 80 grit sandpaper. (IMPORTANT – BOND STRENGTH MAY BE REDUCED IF THIS STEP IS SKIPPED.)

- Wipe surfaces clean from dust with alcohol or acetone using new paper towels, not shop rags.

- If using Plexus MA590 adhesive, apply Plexus PC-120 surface conditioner to inside surfaces of Seakeeper foundation saddles in accordance with manufacturer instructions. These instructions are located at the end of this section. If using an alternate adhesive, check with manufacturer if any surface conditioner/etch is required for the aluminum saddles.

Bonding Saddles to Hull

Note: This is a sample if using Plexus, if using another adhesive follow manufacturer’s recommendations.

If using Plexus MA590 adhesive, the Seakeeper saddles should be installed when PC-120 is confirmed dry.

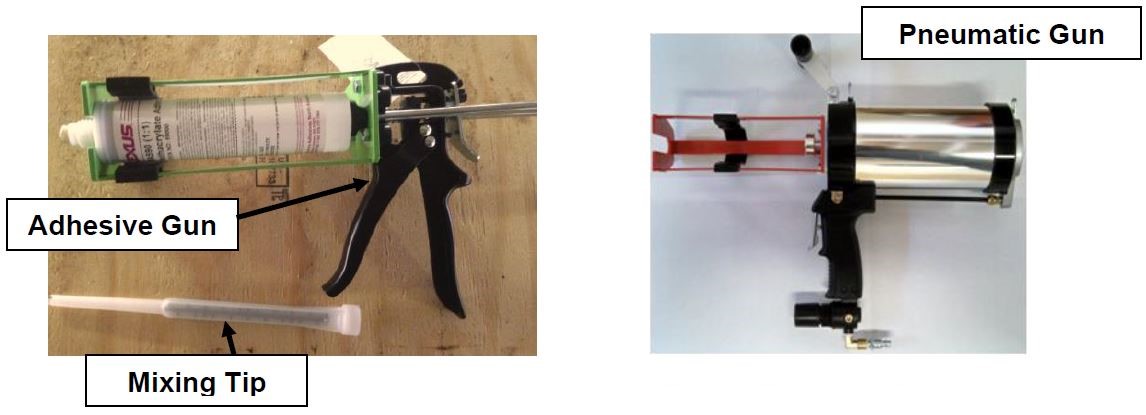

- Assemble Plexus cartridge into either the manual or pneumatic gun as shown. Remove cap on cartridge and attach mixing tip. For pneumatic gun, start with low air pressure and increase until desired flow rate is achieved.

- Cut tip of mixing wand as shown in photo below.

- Prepare a second mixing wand as shown in photo below by attaching the simple flexible nozzle to the end of the mixing tip. Set aside for now as this will be used to inject adhesive into the sides of each saddle after the fixture / saddles are in position.

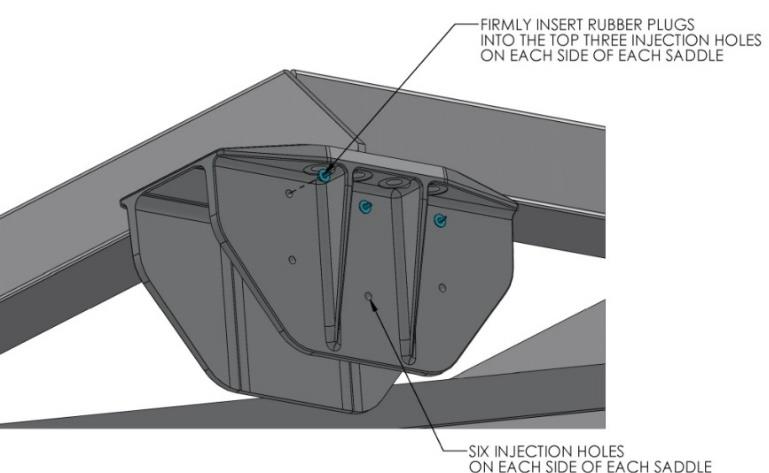

- Install provided rubber plugs in 12 holes of each saddle. The plugs will limit the adhesive being forced out of the injection holes in step 6 below.

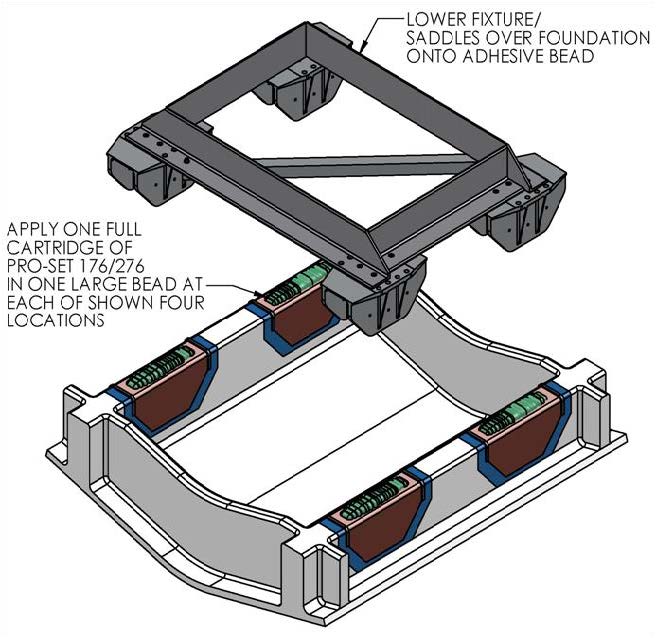

- Apply large bead of Plexus adhesive to the hull structure as shown in the figure below. Apply approximately 1½ cartridges at each of the four locations. Work deliberate and fast as it takes some time to apply the adhesive to the structure. MA590 has a 90-minute working time at room temperature (73°F / 23°C). This working time can reduce to 40-50 minutes at elevated temperatures. Two workers should apply the adhesive at the same time to finish the installation before the adhesive starts to cure.

- Lower fixture and saddles over the hull structure and apply light downward pressure to each of the four saddles until the four nylon screws rest on the hull structure (see Figure 9). The adhesive will be forced towards the forward and aft ends of each saddle and partially down the sides of the foundation beams.

- Insert full adhesive cartridge along with mixing wand / nozzle assembled in Step 3 above, into gun.

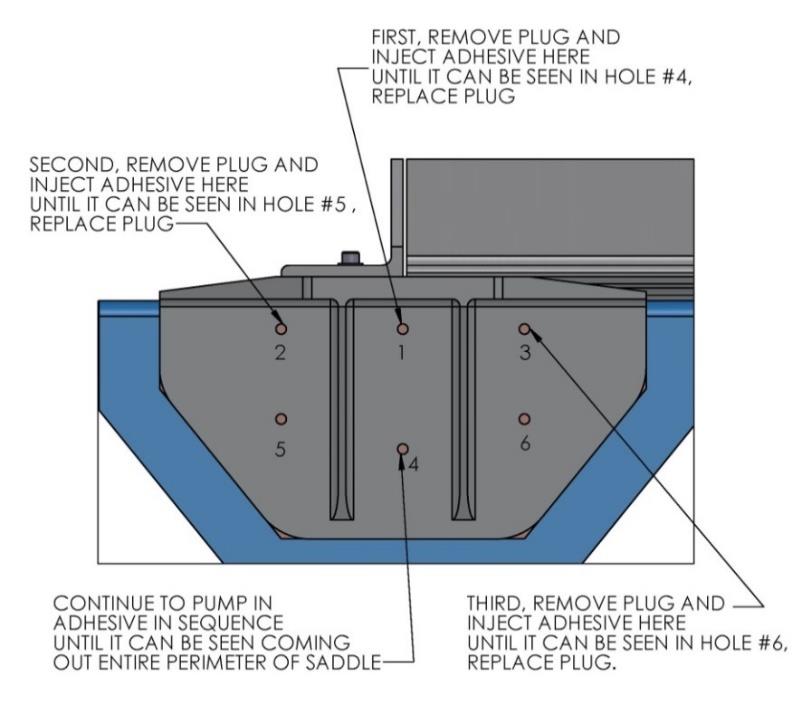

- Begin to inject adhesive into the six holes provided on each side of each of the four saddles. Follow the numbered sequence shown until the adhesive pushes out the edges of the saddle perimeter. The intent is to pump in the adhesive working from the top down and from the middle to the ends to fill the gaps and displace any air. A complete bond is required – excess adhesive will be needed to make sure all bond gaps are filled.

- Repeat above step for remaining 7 sides of the saddles.

- When gaps have been completely filled, clean off excess adhesive, remove foam tape, remove plugs, and remove masking tape.

- Allow adhesive to cure per manufacturer’s recommendations. Follow adhesive guidelines for curing time versus temperature prior to removing the fixture.

- Bonding of Seakeeper saddles onto the hull is now complete. Remove installation fixture.

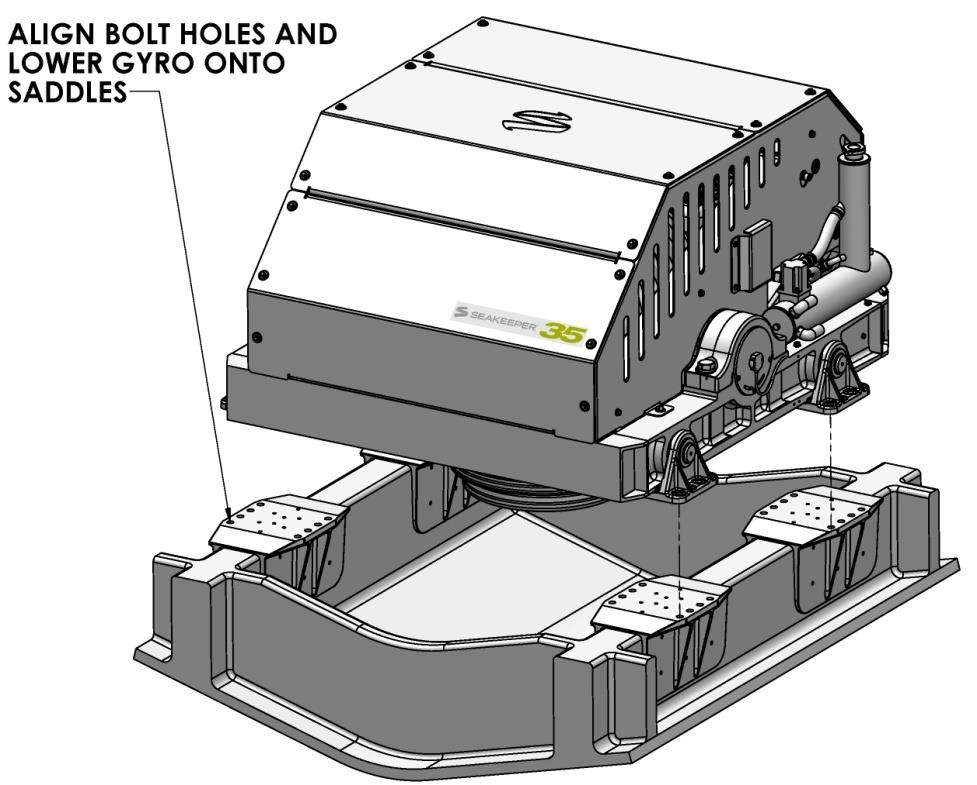

Installation of Seakeeper

- Rig Seakeeper for lifting and lower it into position onto top surface of four saddles.

- Apply a small bead (approximately 4 mm wide) of sealant or caulk to the mating surfaces between the saddles and the Seakeeper foundation. Adjust position of the Seakeeper until alignment is achieved for the 32 fasteners that will attach the foundation frame to saddles. (Note: isolation gasket used for bolt-in installation is not required).

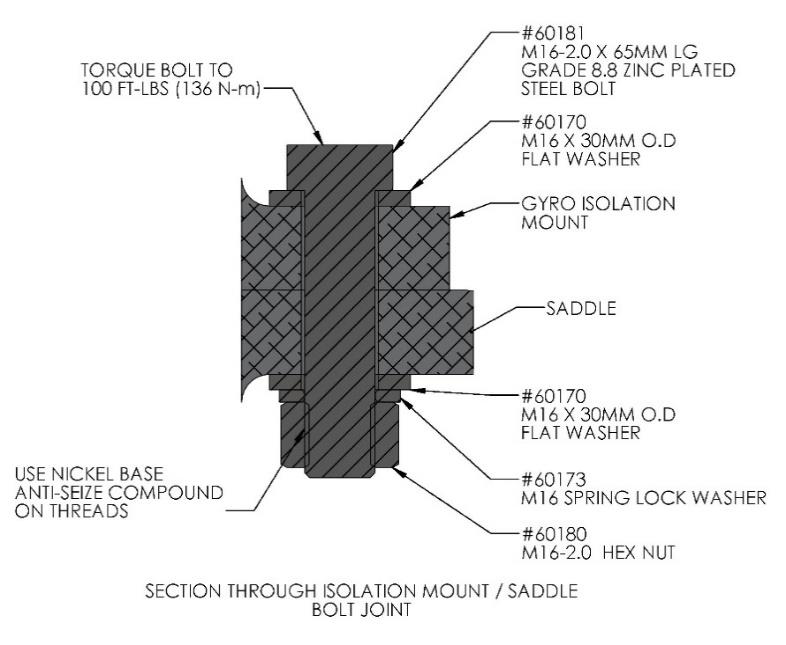

- Install Seakeeper supplied M16 fasteners as shown in figure below – apply a moderate coat of nickel based anti-seize compound to the threads of each bolt prior to installation and a small amount of sealant to the washer faces.

- Torque all fasteners to 100 ft-lbs (136 N-m).

- Proceed to electrical and cooling portion of the installation.