Seakeeper 16/18/12HD Installation Manual (90549-2)

Electrical Installation

Electrical Installation Introduction

This section for electrical installation explains how to mount the electrical equipment and how to connect the electrical cables.

Reference Documents & Drawings:

Link to Seakeeper 26/20HD Reference Documents

- 90243 – Seakeeper 16 Hardware Scope of Supply

- 90538 – Seakeeper 18 Hardware Scope of Supply

- 90550 – Seakeeper 16/18 Operation Manual

- 90467 – 2nd Helm Control Station Kit

- 90539 – Seakeeper 16/18 Cable Block Diagram

- 90438 – 5″ Operator Display Envelope and Mounting Details

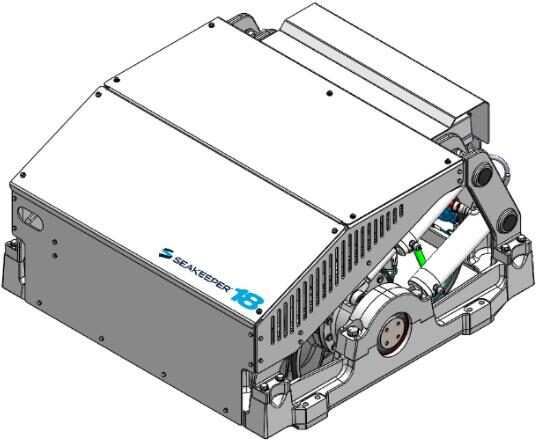

Figure 1 – Electrical Equipment for Seakeeper 16/18

Electrical Equipment Mounting

Precautions: Each item of electrical equipment has specific mounting instructions. These instructions

should be followed to ensure proper function of the Seakeeper.

Do NOT move Seakeeper mounted components from their

locations or incorrect Seakeeper operation will result.

- Touch Display Mounting Instructions, Surface Mount

- Console space required: Approx. 5.24 W x 3.70 H in. (133 x 94 mm)

- Mounting Instructions, Surface Mount: See Drawing No. 90438 – 5″ Operator Display Envelope and Mounting Details, for details. Seakeeper Touch Display 3D Model available upon request.

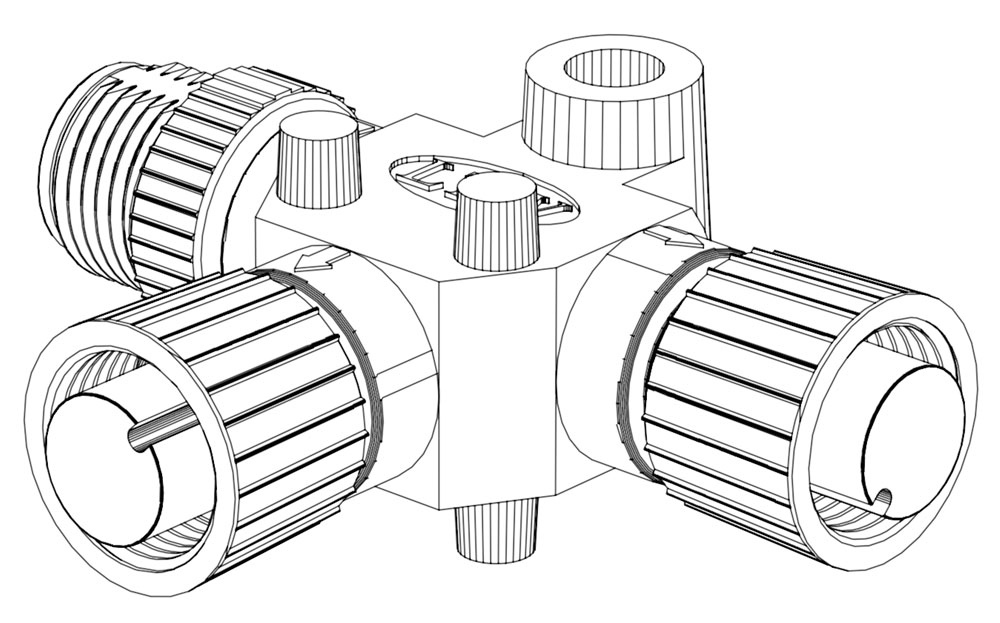

- CAN Communications Tee Adapter and Terminator Mounting Instructions

- Console space required, Rear: Approx. 4 W x 3 H in. (102 x 76 mm)

- Mounting Instructions: Rear mount on vessel console panel, within 2 ft (0.6 m) of Display.

- Hardware required: One mounting screw for .197 in. (5 mm) diameter mounting hole on Tee Adapter.

- USB Extension Cable Assembly Mounting Instructions

- Console space required: Approx. 2 W x 2 H in. (51 x 51 mm), within 6 ft (2 m) from Touch Display.

- Mounting Instructions, Surface Mount: Use panel cutout as shown in Section: Display Installation Template. Maximum panel thickness 1/8 in. (3.2 mm).

- Install sealed USB connector end of the extender cable assembly in panel from rear and secure with hex jam nut (provided) on front.

- Connect M12 connector end of the extender cable assembly to the rear of the Touch Display on receptacle AUX.

- Multi-Function Display Integration Instructions

- The following Technical Bulletins outline the instructions for MFD Integration:

- TB 90478 – Garmin and Seakeeper Compatibility

- TB 90479 – Raymarine and Seakeeper Compatibility

- TB 90480 – Simrad and Seakeeper Compatibility

- Additional MFD Compatibility will be added as new integrations become available. Please contact Seakeeper for additional information.

- Seakeeper MFD Compatibility cable part numbers can be found in the relevant technical bulletin for the specific MFD, listed above.

- The following Technical Bulletins outline the instructions for MFD Integration:

Electrical Equipment Power Connections

230 VAC Power Source Requirements

- 230 VAC (nominal), 1 Phase, 50/60 Hz, 30 A

- With installations of more than one Seakeeper, a separate circuit breaker should be used for each Seakeeper Motor Drive Box.

Drive Box AC Power Input Connection Instructions

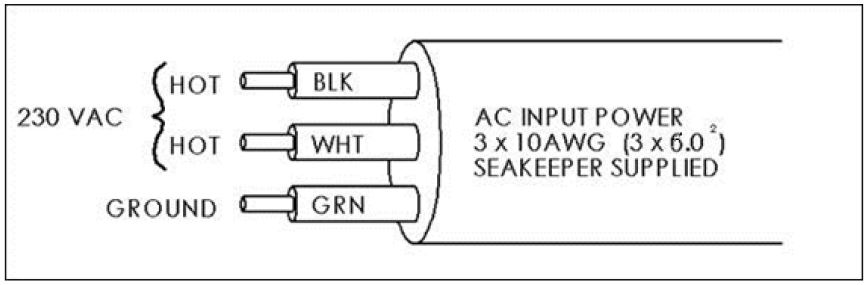

- Cable: 3 x 10 AWG (3 x 6 mm2 CSA), 10 ft (3 m) length, Seakeeper supplied pre-installed.

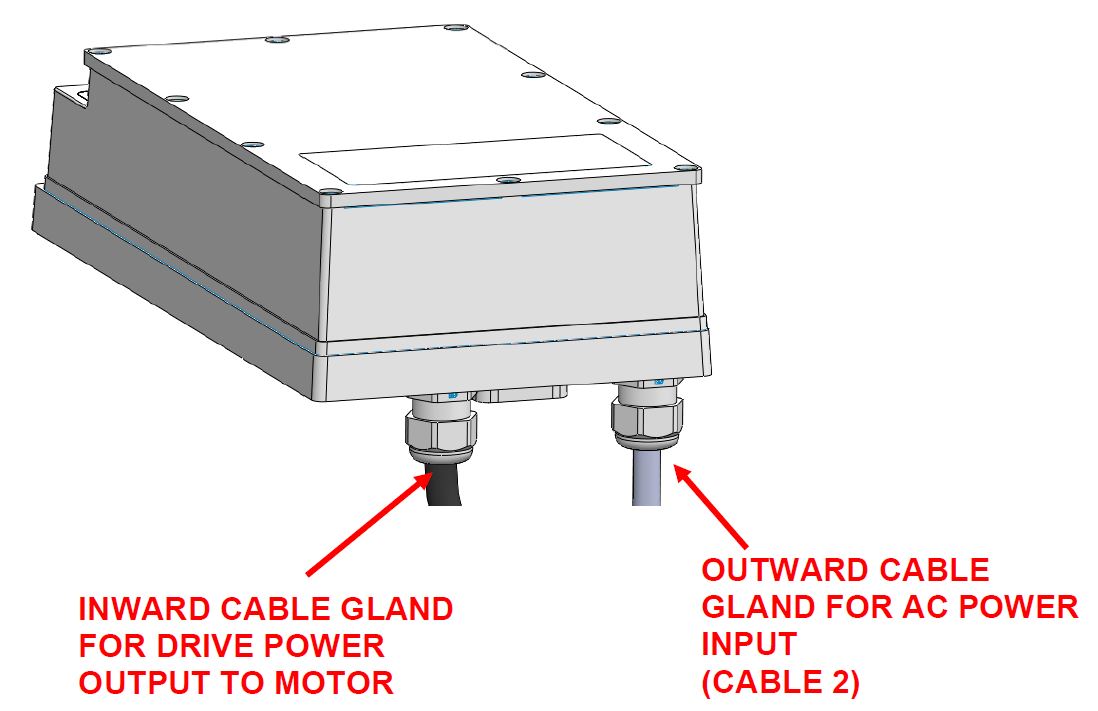

- Locate Cable 2 for AC power input to the Motor Drive Box at the outward of two cable glands.

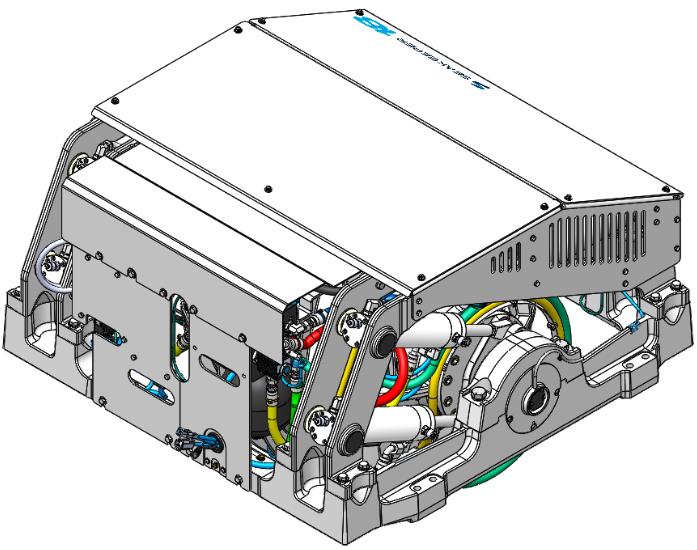

Figure 2 – Motor Drive Box AC Power Input & Output Cable Glands

Figure 3 – Cable 2 Wire Connections at AC Power Distribution Panel - Connect 230 VAC wires in Cable 2 to a 30 A, double-pole Circuit Breaker at an AC power distribution panel according to Figure 3 above.

- Locate Cable 2 for AC power input to the Motor Drive Box at the outward of two cable glands.

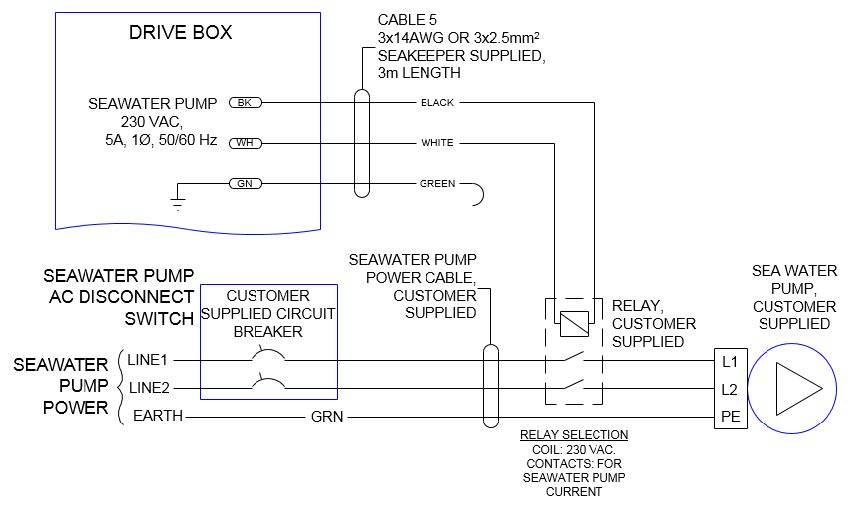

DC Power Output to Seawater Pump Connection Instructions

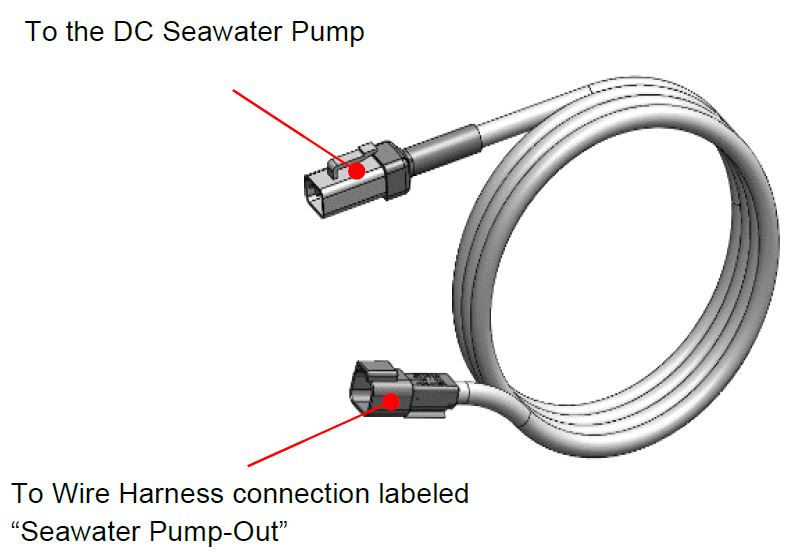

- Cable 5: P/N 20455, DC Output Power, 14 AWG, DTP Male-Female, Cable Assembly, Seakeeper supplied (5 m length)

- Cable 8: P/N 20454, DC Input Power, 14 AWG, DTP Female Only, Cable Assembly, Seakeeper supplied (5 m length)

- Seakeeper P/N 30322, Seawater Pump rated at 24 VDC, Fuse or Circuit Breaker 10 A Required

- Alternative: Seawater Pump rated at 24 VDC, Max Fuse Rating Labeled by MFR (LESS THAN 20 A)

Verify that DC power is OFF to the Drive Box before connecting both cables to a Seawater Pump.

Verify that DC power is OFF to the Drive Box before connecting both cables to a Seawater Pump. - Locate Cable 5: P/N 20455, DC Seawater Pump Output Power Cable Male-Female connection to the DC “Seawater Pump-Out” from the Wire Harness.

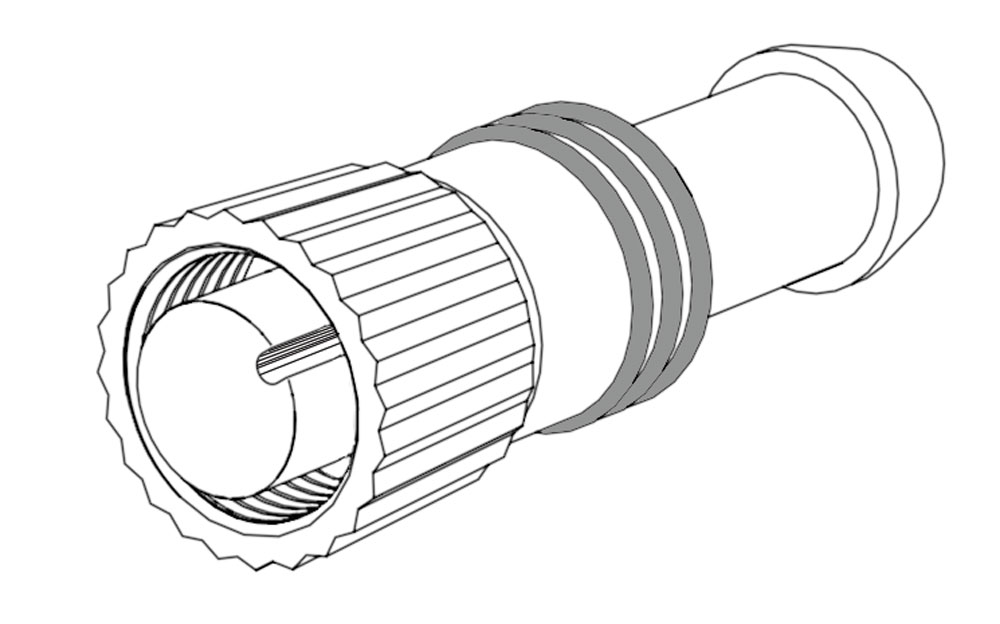

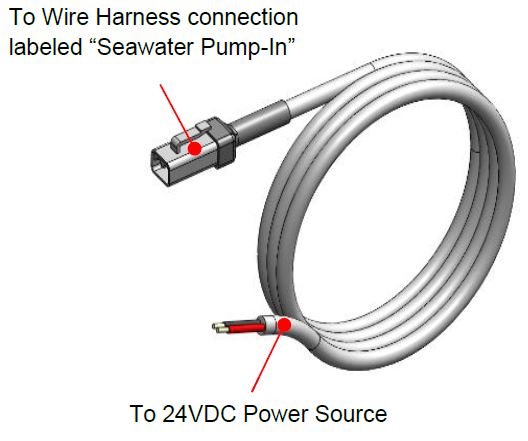

Figure 4a – Cable 5, P/N 20455, DC Seawater Pump Output Power Cable, Male-Female - Locate Cable 8: P/N 20454, DC Seawater Pump Input Power Cable, Female Only connection to the DC “Seawater Pump-In” from the Wire Harness. Stripped end to be connected to a 24 VDC power source.

Figure 4b – Cable 8, P/N 20454, DC Seawater Pump Input Power Cable, Female Only - Connect Cable 8, P/N 20454, DC Seawater Pump, Input Power Cable, Female Only wires to a 24 VDC power source according to Figure 5.

- Alternative: Seawater Pump rated at 24 VDC, Max Fuse Rating Labeled by MFR (LESS THAN 20 A)

24 VDC Power Source Requirements

- 24 VDC, 10 A

- A separate breaker should be used for each Seakeeper.

- Wire Harness, 24 VDC, 10 A

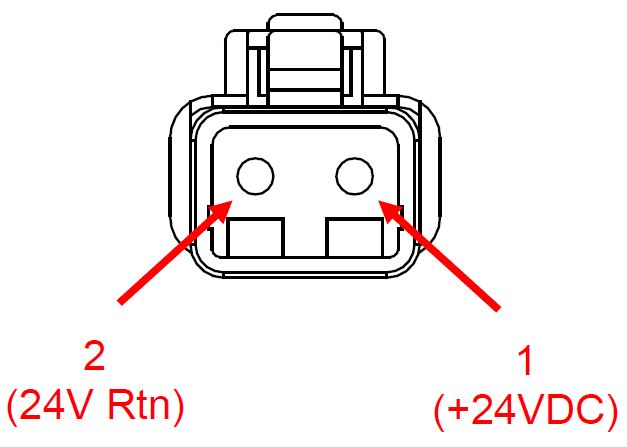

DC Power Connection Instructions

Reversing polarity on the DC power input to the Seakeeper can result in damaging the electronics in the control system.

- 24 VDC, 10 A, 2 x 12 AWG (3 x 4 mm2 CSA) customer supplied.

- Install Seakeeper provided DC Power Input Cable, P/N 20248, as Cable 1.

- Route Cable 1 to DC Power Distribution Panel.

- Terminate red conductor to +24 VDC. Terminate black conductor to 24 V Rtn or 0 VDC.

- Before connecting Cable 1 to Seakeeper, check for proper voltage and polarity with a DC multimeter using Figure 6 below.

- Connect Cable 1 to 24 VDC input receptacle on Seakeeper.

- Install Seakeeper provided DC Power Input Cable, P/N 20248, as Cable 1.

When energizing DC power for the first time, if Display does not power up immediately then disconnect and inspect connector polarity.

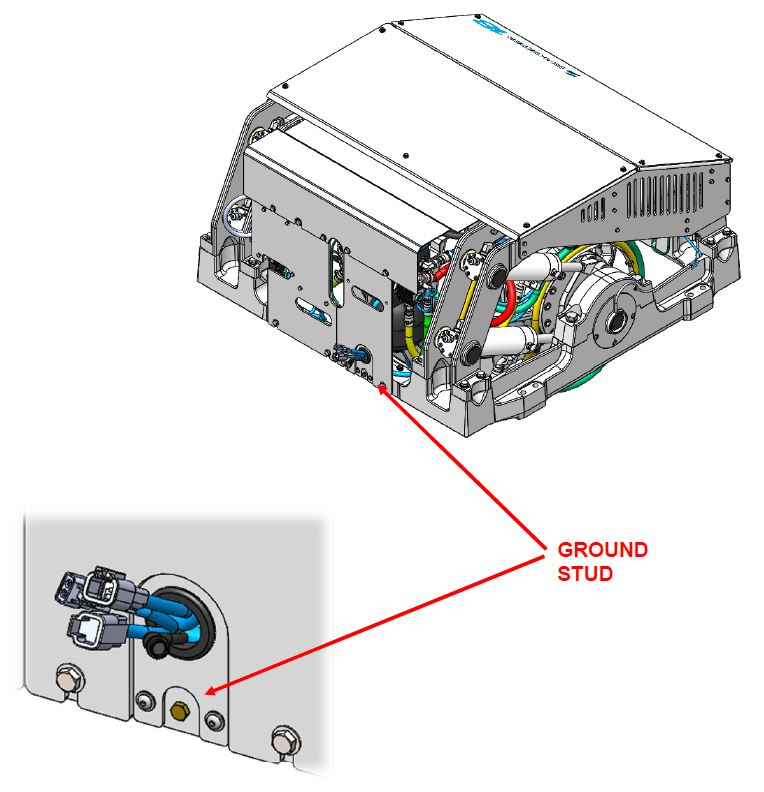

Electrical Equipment Ground Connections

Seakeeper to Vessel Ground Connection Instructions

- Connect the Seakeeper foundation to vessel ground.

- Install Cable 6 (10 AWG or 22.0 mm2, customer supplied) from the M6 brass ground stud on the Seakeeper rear brace to a suitable vessel ground.

Note: ONLY USE THIS LOCATION FOR GROUNDING THE SEAKEEPER TO THE VESSEL GROUND.

- Install Cable 6 (10 AWG or 22.0 mm2, customer supplied) from the M6 brass ground stud on the Seakeeper rear brace to a suitable vessel ground.

Operator Station

This section explains the connection between the Operator Station equipment and the Seakeeper.

Reference Documents & Drawings

- 90539 – Seakeeper 16/18 Cable Block Diagram

Determine Location of Operator Station

- The desired location of the Operator Station must be determined with respect to the vessel arrangement.

- The operator display should be located on the bridge console.

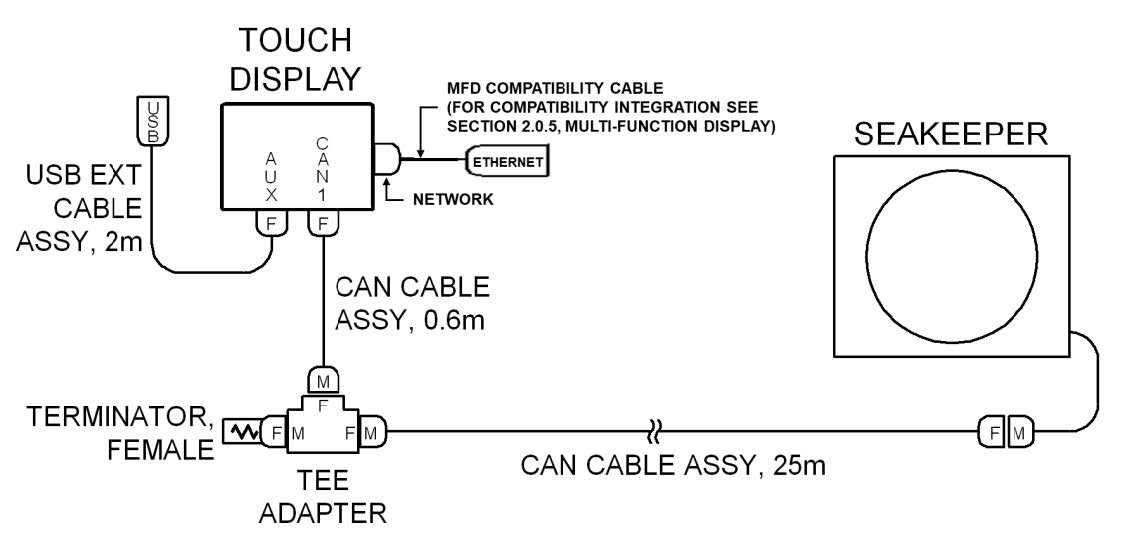

- Figure 8 below shows the CAN bus communications link for the Operator Station. The Terminator goes on the far end of the Tee Adapter from the Seakeeper.

Route Serial Communications Cable

- The CAN Cable Assembly (P/N 30243, Cable 3) is a 25 m shielded cable and the largest connector is a molded plug with maximum outer diameter of .58 in. (14.8 mm).

- Cable 3 must be routed and installed in the vessel from the Seakeeper (female end) to the Tee Adapter (male end) at the Operator Station.

Install Operator Station Equipment

- The Operator Station equipment is installed at the selected location using instructions found in Section: Electrical Equipment Mounting.

Connect Operator Station Equipment

- The Operator Station equipment is connected in accordance with Drawing No. 90539 – Seakeeper 16/18 Cable Block Diagram.

Second Operator Station Connection

This section explains how to connect the 2nd Operator Station Kit.

Reference Documents & Drawings

- 90467 – Helm Display 2nd Operator Station Kit

- 90539 – Seakeeper 16/18 Cable Block Diagram (includes detail of 2nd Operator Station)

Determine Location of 2nd Operator Station

- The desired location of the 2nd Operator Station must be determined with respect to the 1st Operator Station and the vessel arrangement.

- Typical locations include:

- Flybridge

- Engine room

Determine Cabling Arrangement

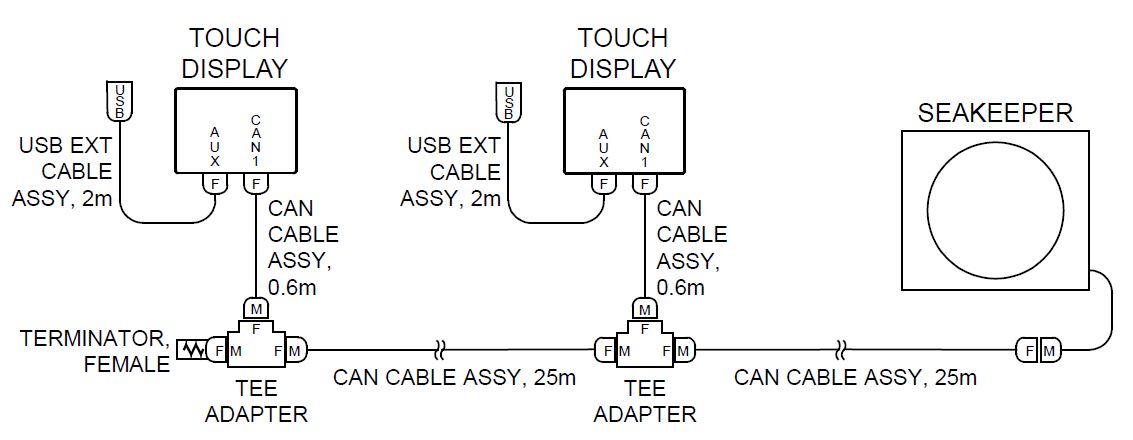

- Figure 9 below shows the entire serial communications link for 2 Operator Stations. The Terminator must be installed on the Tee Adapter farthest from the Seakeeper.

- The Operator Station nearest the Seakeeper should be connected to Cable 3.

Route 2nd Operator Station Cable

- A second CAN Cable Assembly (P/N 30243), also a 25 m shielded cable, and the largest connector is a molded plug with maximum outer diameter of .58 in. (14.8 mm).

- The additional CAN Cable Assembly must be routed in the vessel from the 1st Operator Station (female end) to the 2nd (male end) Operator Station.

Install 2nd Operator Station Equipment

- The 2nd Operator Station equipment is installed at the determined location using instructions found in Section: Electrical Equipment Mounting.

Connect 2nd Operator Station Equipment

- The 2nd Operator Station equipment is connected in accordance with Drawing No. 90539 – Seakeeper 16/18 Cable Block Diagram.