Seakeeper 9 Operation Manual (90223-10); S/N 9-233-4900 to Current

4.0 Power Failures, Alarms, and Troubleshooting

4.1 Power Failures and Alarms Introduction

The Motor Drive Box contains hazardous voltage and the cover should not be removed while the flywheel is spinning and the AC input voltage is present. This high voltage exists even if the flywheel is coasting down and the supply voltage has been shut off. The flywheel must be at 0 RPM and AC input power disconnected for at least 10 minutes prior to any service work on the motor drive box.

____________________________________________________________________________________________

The operator should physically examine the Seakeeper following an alarm. Continuing to reset alarms without service intervention can result in damage or personnel injury.

____________________________________________________________________________________________

The flywheel must be at Zero (0) RPM and AC input power disconnected for at least 10 minutes prior to any service work on the Seakeeper.

The Seakeeper 9 has safety features, such as alarms and warnings, that pop-up on the Seakeeper

Application and are signaled on the ConnectBox to protect the Seakeeper as well as the vessel. The brake can be locked from the Application, ConnectBox or by shutting off power at the supply breakers, preventing the Seakeeper from precessing.

In the event of a DC control power failure, the brake automatically locks the Seakeeper so it cannot generate anti-rolling torque loads.

There are three sources of power to the Seakeeper 9:

- 24 VDC powers the Seakeeper for all the control electronics.

- 24 VDC powers the DC Seawater Pump for cooling water supply.

- 208 – 230 VAC powers the Motor Drive Box to drive the motor inside the Seakeeper.

These are supplied on cables shown on Drawing No. 90257 – Seakeeper 9 Cable Block Diagram.

4.2 DC Power Failure

24 VDC Control Power

If the 24 VDC is disconnected during operation, the display will be blank, flywheel speed will decrease, and the brake will be locked (no precession).

- Verify the boat’s circuit breaker supplying +24 VDC has not tripped and the AC breaker is On.

- When +24 VDC is restored, the display will power up, the Splash Screen will appear, and then the Home Screen will appear.

- Press Power On/Off button

. The progress bar will appear and indicate flywheel speed. When the flywheel is at minimum operating speed, the Stabilize button will appear so stabilization can be turned on. This may take up to 30 minutes, depending on the speed of the flywheel when the +24 VDC is turned back on.

. The progress bar will appear and indicate flywheel speed. When the flywheel is at minimum operating speed, the Stabilize button will appear so stabilization can be turned on. This may take up to 30 minutes, depending on the speed of the flywheel when the +24 VDC is turned back on.

Seawater Pump Power

If Seawater Pump input DC power is disconnected during operation, the Seawater Pump will fail to provide cooling seawater flow when required. The resulting high temperatures would result in the Seakeeper being turned off (no stabilization) due to high temperature alarm(s).

- Verify the boat’s circuit breaker or fuse supplying DC Seawater Pump power has not tripped or blown.

- When DC SW Pump power is restored, reset any alarm and continue Seakeeper operation.

4.3 230 VAC Failure

AC Power Failure

If the AC power is not connected, a notification screen will indicate “AC Mains Low”. If the failure is not corrected within two minutes, an “AC Mains Low” alarm will occur. The brake will lock and the Seakeeper will stop moving if stabilization was on.

- Verify the boat’s circuit breaker supplying 208-230 VAC to the Motor Drive Box has not tripped.

- When 208-230 VAC is restored, the display will power up, the Splash Screen will appear, and then the Home Screen will appear.

- Press Power On/Off button

to clear the alarm. The progress bar will appear and indicate flywheel speed. When the flywheel is at minimum operating speed, the Stabilize button will appear so stabilization can be turned on. This may take up to 30 minutes, depending on the speed of the flywheel when the 208-230 VAC is turned back on.

to clear the alarm. The progress bar will appear and indicate flywheel speed. When the flywheel is at minimum operating speed, the Stabilize button will appear so stabilization can be turned on. This may take up to 30 minutes, depending on the speed of the flywheel when the 208-230 VAC is turned back on.

AC Power Fluctuation, Spike, or Momentary Failure

If the AC voltage to the Motor Drive Box is outside Seakeeper’s specified range (208 – 230 VAC), the Motor Drive Box will briefly shut down for protection. The Motor Drive Box will continue operation when the voltage returns to the specified range.

A brief fluctuation can happen when the generator is unable to regulate its output voltage, particularly when a large AC load is switched on or off. A momentary AC failure also happens during transition from shore power to ship’s power.

4.4 Alarms and Troubleshooting

Alarms

The operator should physically examine the Seakeeper following an alarm. Continuing to reset without service intervention can result in damage or personnel injury.

Sensors, alarms, and shutdowns are provided to allow unattended operation. Sensors measure drive temperatures, gimbal angle, brake pressure, and vessel motion. The Seakeeper controller sends sensor values and alarm information to the display and locks the brake and shuts down the motor drive in the event of an alarm condition. Seakeeper operating history during faults or alarms is recorded in the controller’s memory for subsequent recall if service is needed. Seakeeper and Seakeeper Dealers may access the Seakeeper’s software to gather run hours, bearing loading, and hull slamming information.

NOTE: Only the MFD app or the Seakeeper 5” Touch Display can identify and address the alarm. The alarm will not clear until the operator presses the Reset Alarm button, AND the alarm condition is no longer present. The operator can then press the POWER button again to resume Seakeeper operation.

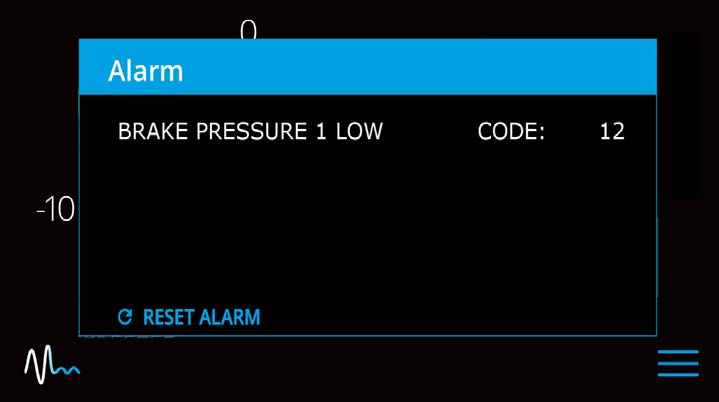

- A view of a typical Alarm screen.

- To reset the alarm, press the Reset Alarm button:

Troubleshooting

- At MFD app or 5″ Touch Display, check for alarms or warnings.

- Power Supply: Check electrical power source breakers ON or fuses installed and NOT blown.

- Mechanical Components:

- For temperature -related alarm, verify the coolant reservoir is filled with glycol mixture (50% ethylene glycol/50% distilled water). Verify seawater pump power aligned.

- Visually check mechanical fittings and joints for leakage.

- Visually check coolant and brake hoses for chaffing and leakage.

- Contact an authorized Seakeeper dealer for further assistance in diagnosing and resolving complex alarms.

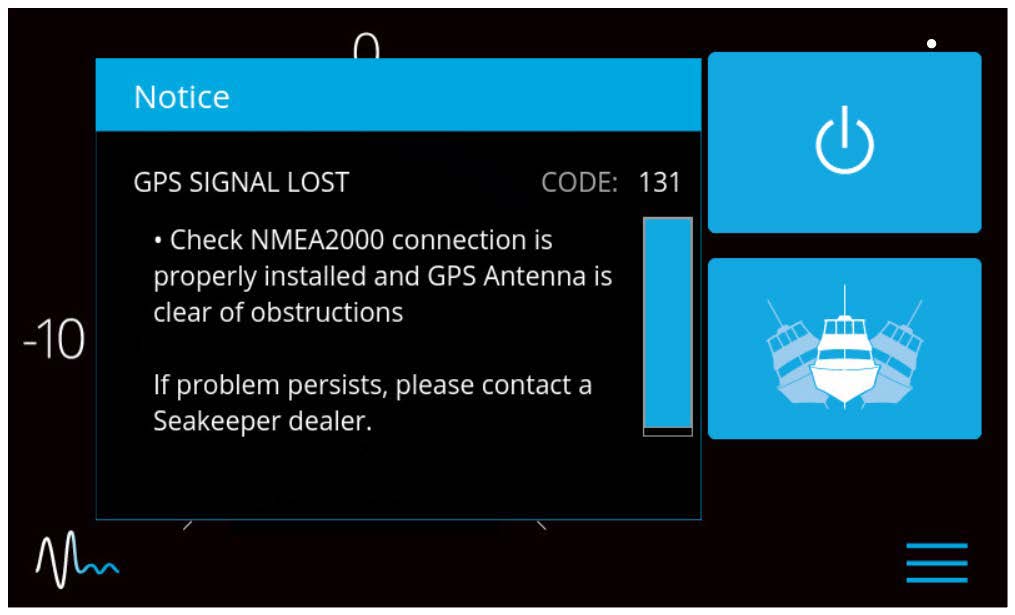

If a GPS signal is lost, a warning message will appear in the Alarm History and a message will appear on the Home Screen, as seen below. The Seakeeper will not spool down, however the precession rate and angle of the sphere will be reduced until GPS signal returns.

4.5 Alarm History

The operator should physically examine the Seakeeper following an alarm. Continuing to reset alarms without service intervention can result in damage or personnel injury.

The ALARM HISTORY page on the Seakeeper application or display shows the recent alarms and warnings. Alarms trigger a pop-up message to be displayed on the display or Seakeeper App. Warnings will be listed in the alarm history but do not affect Seakeeper operation. The alarms and warnings are in chronological order starting with the most recent. Warnings included in the history page are for issues that do not affect gyrostabilizer operation.

Press the Menu button ![]() to show the page options and then the Alarm button

to show the page options and then the Alarm button ![]() to show alarm history.

to show alarm history.