Seakeeper 9 Operation Manual (90223-10); S/N 9-233-4900 to Current

Seakeeper 9 Operation Manual (90223-10); S/N 9-233-4900 to Current

1.0 Introduction

Seakeeper 9

Operation Manual

90233, Revision 10

This Operation Manual is applicable to the Seakeeper 9 (9-233-4900 to Current)

2.0 System Overview

2.1 System Overview Introduction

The Seakeeper 9 uses gyroscopic principles to reduce boat roll motions in waves and wakes independent of boat speed. In installations involving multiple Seakeepers, each Seakeeper operates independently of one another; therefore this manual only discusses the operation of a single unit.

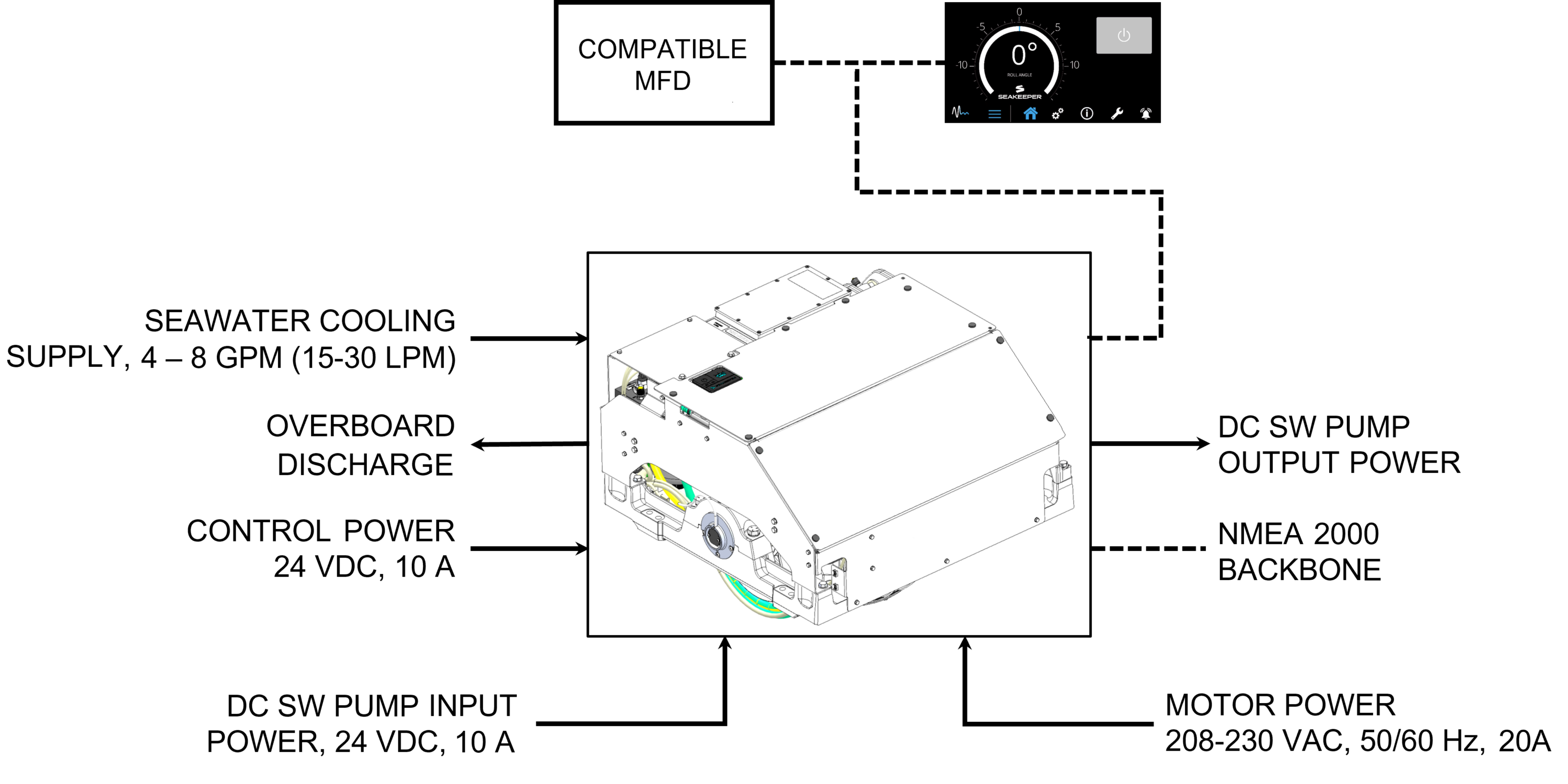

A Seakeeper 9 consists of a Gyro assembly, a CAN communications cable, and a Display. Figure 1 illustrates the interconnection of these components and their interface with the boat.

Seakeeper 9 technical specifications provided in Section: Specifications and Summary, list the power consumption, total weight, and dimensions of the major components. Gyroscopic principals that apply to boat roll control are discussed on Seakeeper’s website at www.seakeeper.com. The Seakeeper website also contains videos of Seakeeper operation and a variety of different boats operating in waves with the Seakeeper on and off. It is recommended that the reader play these videos prior to reading the remainder of this manual.

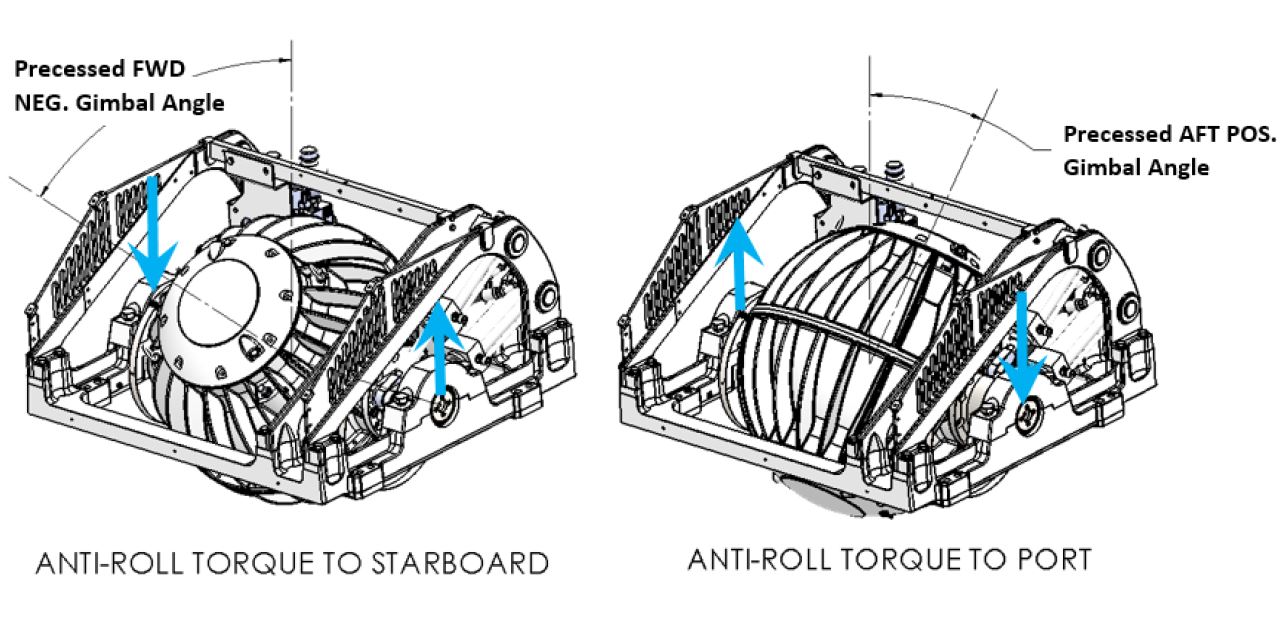

The gimbal angle and the rate of rotation about the gimbal axis (termed precession rate) play an important role in its operation. These parameters are illustrated in Figure 2. At zero degree gimbal angle, the sphere is vertical; it can precess a maximum of +/- 70 degrees about this position. The amount of torque that the Seakeeper exerts on a boat’s hull to counter the wave induced roll is directly proportional to the precession rate. The farther the Seakeeper is from vertical (zero degrees) the lower the anti-roll torque. The vertical arrows in Figure 2 illustrate the direction of the forces that the Seakeeper exerts on the boat’s hull to damp roll motion.

Seakeeper precession is actively controlled by an electronic controller and a hydraulic brake throughout each roll cycle so the Seakeeper supplies the maximum anti-roll torque and does not make mechanical contact with the hard stops that limit the maximum gimbal angle travel to +/- 70 degrees.

There is a large torque about the gimbal axis when the Seakeeper is precessing. Seakeeper cover panels are provided to prevent personnel or equipment from contacting the Seakeeper while it is in operation. These covers should not be stood on or have anything placed on top. The covers should always be in place during operation.

___________________________________________________________________________________________

If it is ever necessary to touch the Seakeeper while the flywheel is spinning, the Seakeeper must be locked at the display to stop the Seakeeper from precessing.

___________________________________________________________________________________________

Seakeeper maintenance should not be attempted unless the Seakeeper is locked, the flywheel has stopped spinning, and AC input power disconnected for at least 10 minutes due to remote start capabilities in some installations.

2.2 Seakeeper Assembly

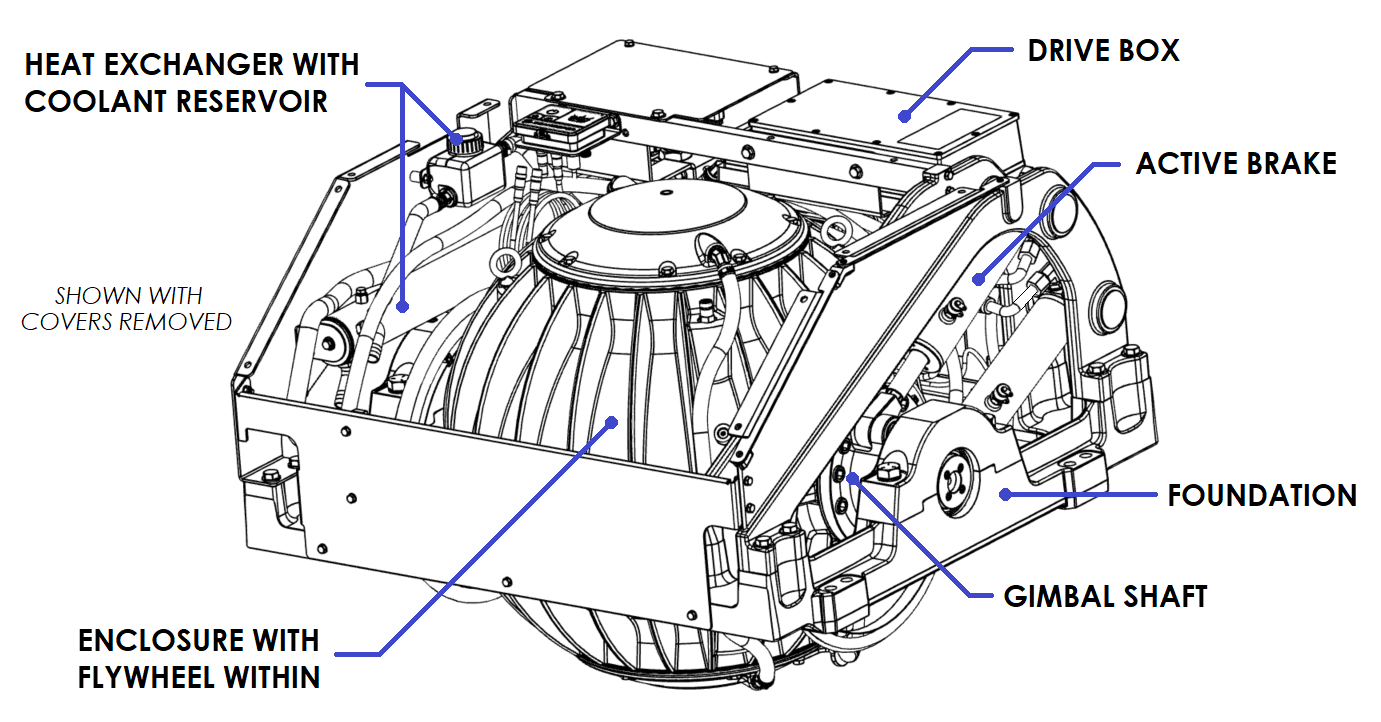

The Seakeeper assembly consists of a flywheel housed in a cast aluminum vacuum-tight enclosure. The flywheel spins about a vertical axis and is supported by upper and lower pairs of bearings. A DC brushless motor mounted inside the enclosure spins the flywheel at high speed.

The enclosure is fastened to two gimbal shafts that are supported by gimbal bearings on either side. These shafts establish an athwartship gimbal axis about which the flywheel and enclosure precess or rotate up to +/- 70 degrees during operation. The gimbal bearings are supported by a foundation which is attached to the hull structure. This foundation transfers the loads that the Seakeeper produces to the hull structure.

An active hydraulic brake mechanism is located on the Seakeeper assembly to regulate the Seakeeper’s precession motions about the gimbal shaft. It includes two hydraulic cylinders and a hydraulic manifold.

A coolant pump, heat exchanger, and reservoir are located near the manifold. A glycol/water mix is circulated through a closed loop to the motor drive box, hydraulic manifold, and the end caps of the enclosure to remove heat.

3.0 System Operation

3.1 ConnectBox and Display Screens: Overview

Introduction

The Seakeeper 9 requires the ConnectBox and connection to either a Seakeeper 5” Touch Display or, preferably, a compatible MFD. The Seakeeper 5” Touch Display and compatible MFD will show the same Seakeeper Application outlined in this section.

When 24 VDC power is applied to the Seakeeper, the ConnectBox will illuminate and the Seakeeper Application on the MFD or 5” Touch Display will initialize. If connecting the ConnectBox to an MFD, and the Seakeeper App does not appear on the MFD, please refer to appropriate Technical Bulletin to troubleshoot, at www.seakeeper.com/technical-library/ and filter for the Seakeeper 9:

- TB-90478 – Garmin and Seakeeper Compatibility

- TB-90479 – Raymarine and Seakeeper Compatibility

- TB-90480 – NAVICO (Simrad/Lowrance/B&G) and Seakeeper Compatibility

- TB-90598 – Furuno and Seakeeper Compatibility

ConnectBox and Home Screen

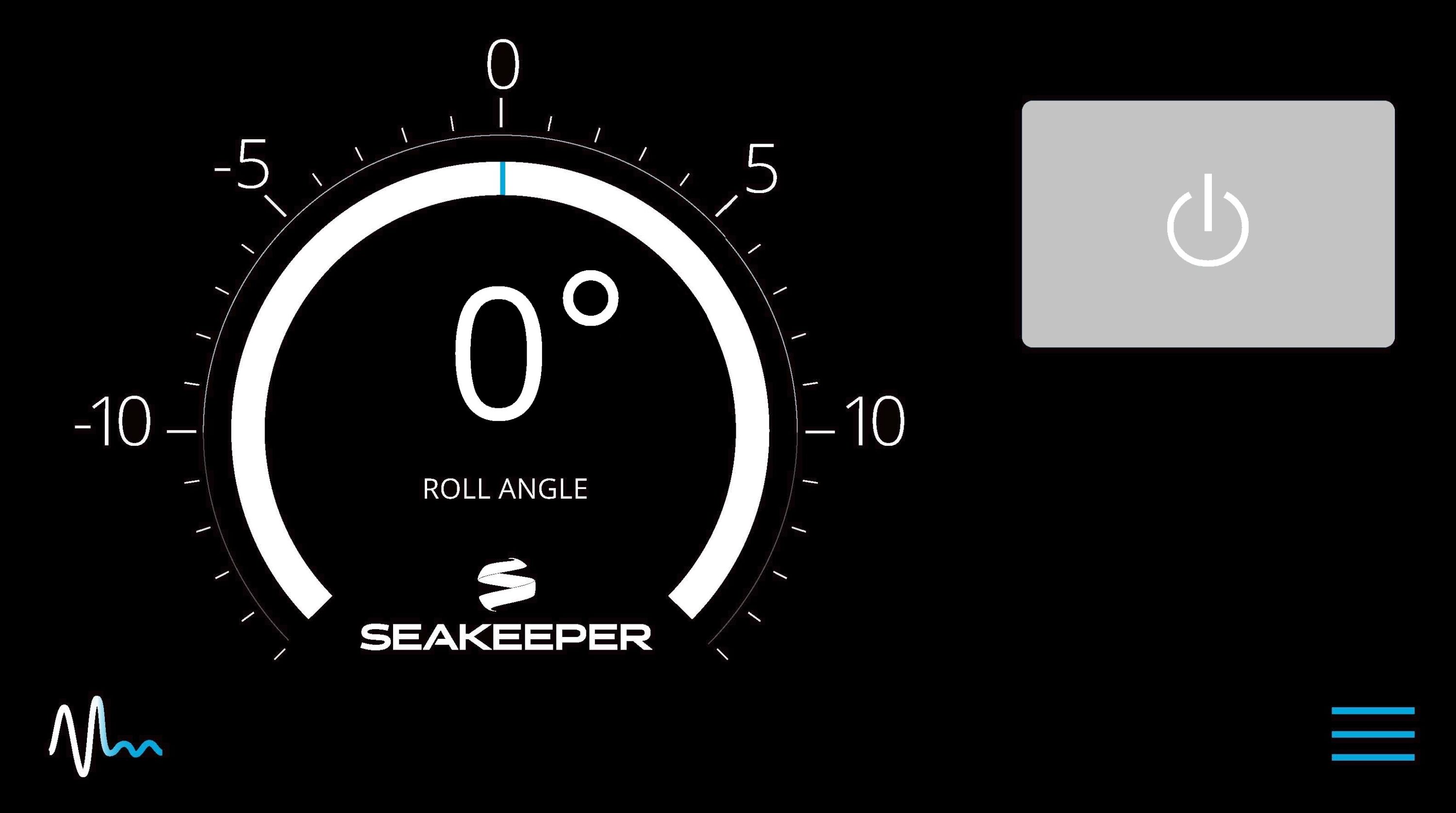

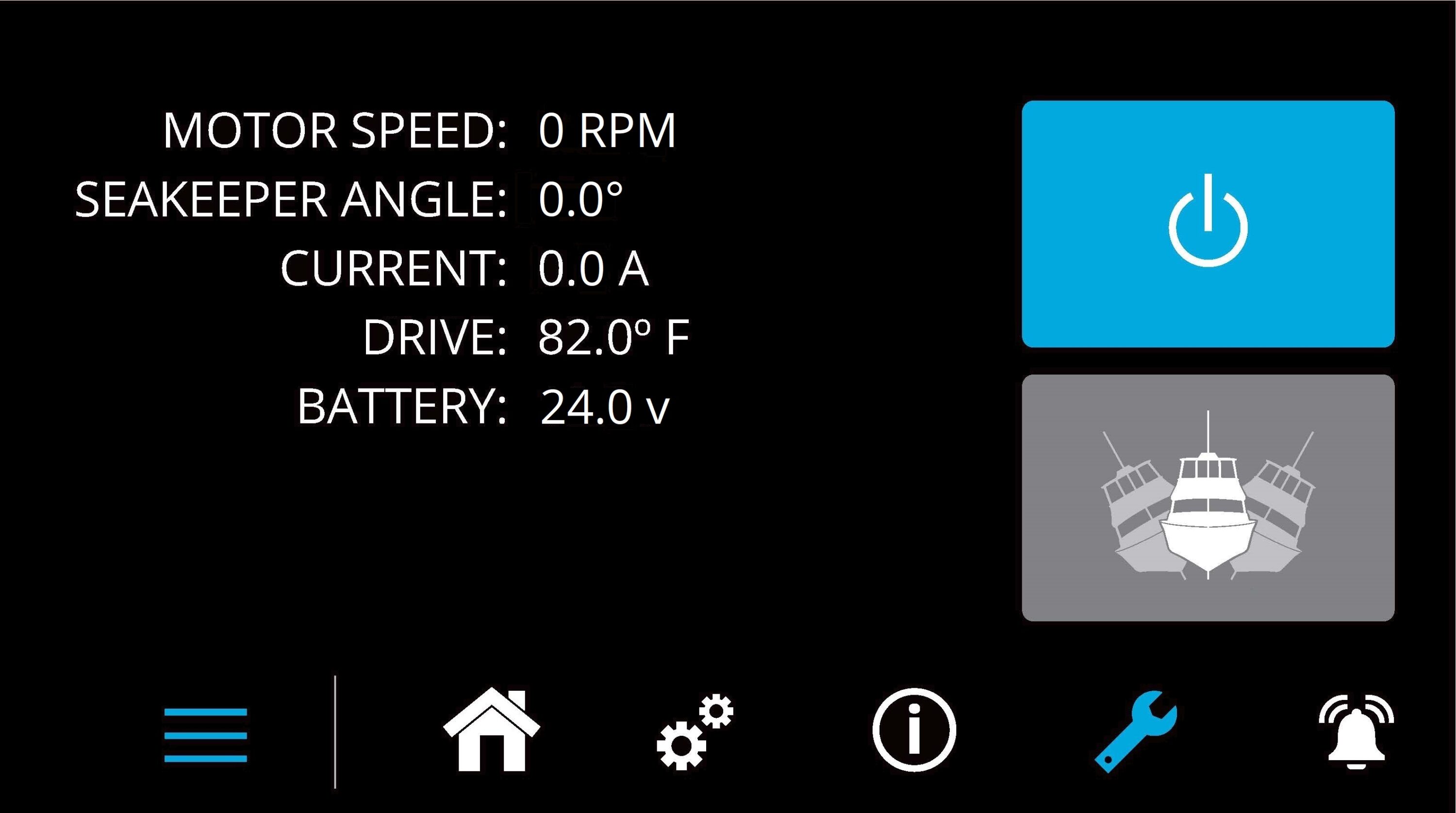

- After the Seakeeper ConnectBox and Application have initialized, the ConnectBox and Application Home Screen will be displayed as shown below.

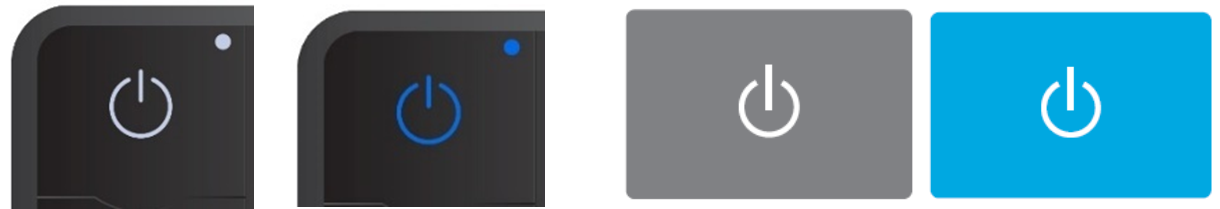

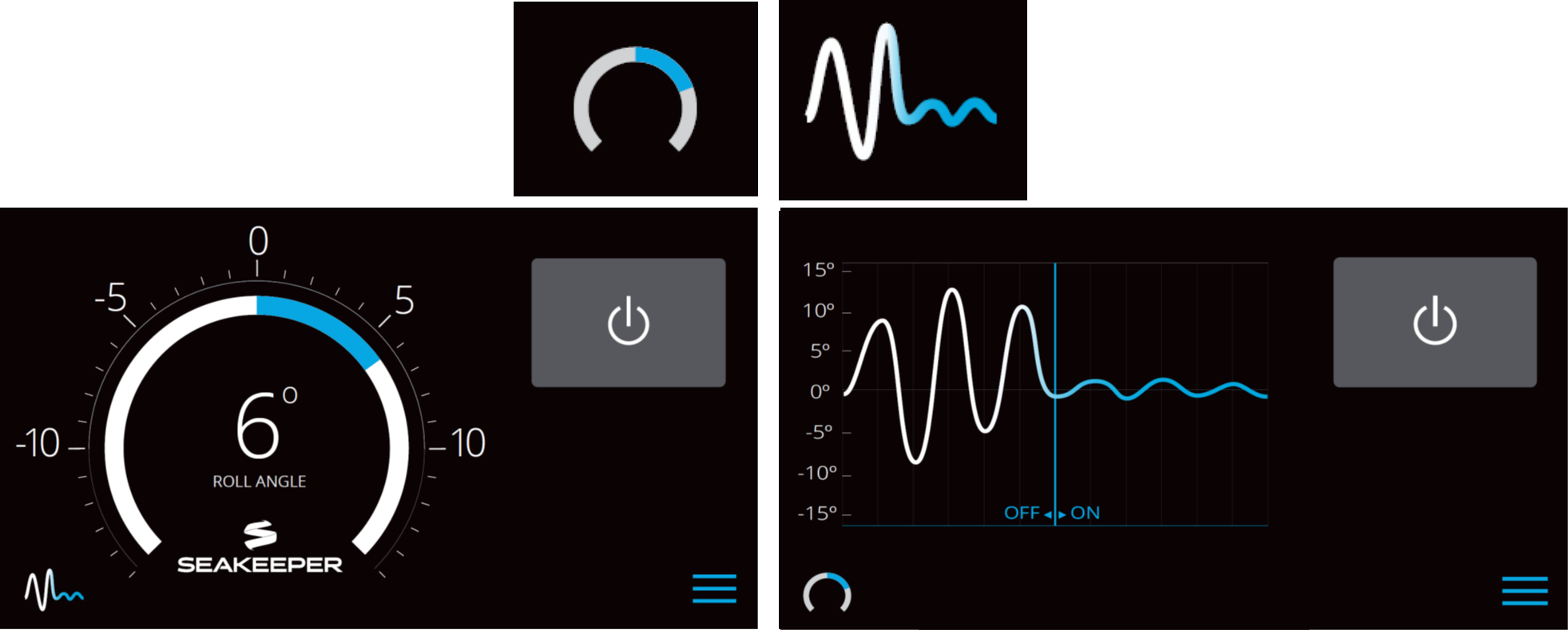

- The Seakeeper can be controlled by either the ConnectBox (shown in images on left) or the Application on the Seakeeper 5” Touch Display or compatible MFD (shown in images on right). Seakeeper POWER button: when pressed, the button will change from grey (Seakeeper Off) to blue (Seakeeper On).

- Seakeeper STABILIZE button: when pressed, the button will change from grey (Stabilize Off) to blue (Stabilize On).

- On the MFD or 5″ Touch Display Application Home Screen view, these buttons can be pressed to toggle Home Screen views between the Roll Angle Gauge and the Roll Angle Graph as shown below.

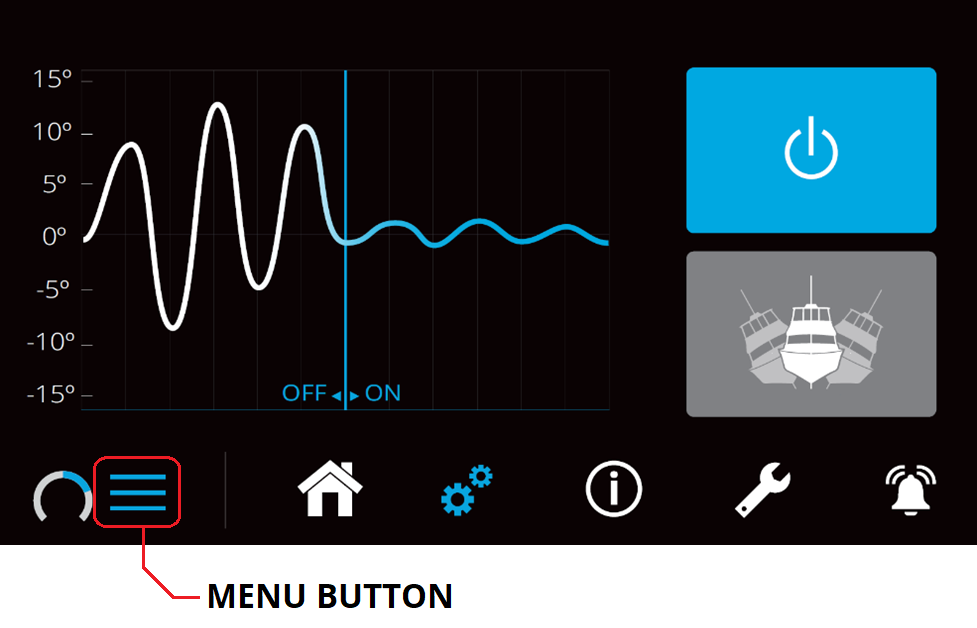

- When the MENU button is pressed,

the Menu Bar will appear or disappear at the bottom of the screen.

the Menu Bar will appear or disappear at the bottom of the screen.

- The Menu Bar is used to navigate between pages. From left to right, the available pages are Home, Settings, Information, Service, and Alarm History. The selected page is highlighted in blue on the Menu Bar.

Settings Page

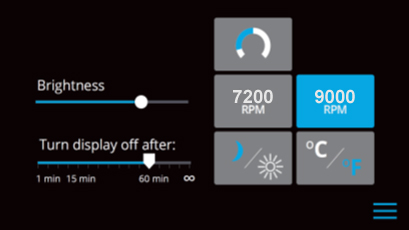

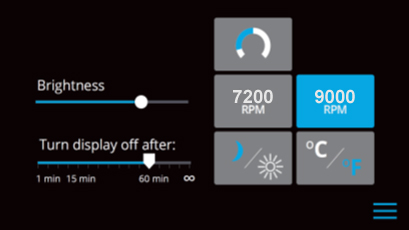

The Settings Page allows the user to adjust their preferences for the display. It can be accessed by pressing the gears ![]() in the menu bar. Settings screen shown below is an example and may appear differently on the installed Seakeeper.

in the menu bar. Settings screen shown below is an example and may appear differently on the installed Seakeeper.

- To increase or decrease the brightness of the display, slide the white dot left to decrease brightness and right to increase brightness on the brightness bar, pictured below on the Settings Page.

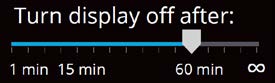

- Adjust the sleep timer from 1 minutes to 60 minutes or on all of the time using sleep time slider. Touching the screen will wake the display up after it has gone to sleep.

- Change the sign of the roll angle value displayed in the roll angle gauge so the gauge matches the motion of the boat. This will depend on installation orientation and will only need to be adjusted once. If the Seakeeper is facing the bow of the vessel, the Roll Angle Gauge should show the blue on the left (pictured left). If the Seakeeper is facing the stern of the vessel, you should select the Roll Angle Gauge with the blue on the right (pictured right). A positive roll angle should be displayed when the vessel rolls to starboard.

- Change the speed of the Seakeeper between normal operation and low power operation. Low power mode consumes less power and should generate less noise. The selected speed is colored blue. When power is cycled (or Seakeeper turned Off), this speed will default back to the normal operating speed. Speed selection buttons shown below are examples and may not match operating speed of installed Seakeeper.

- Change the display between day and night mode. The selected mode is colored blue and to change between day and night mode, press the button.

- Change the units of the temperatures displayed on the Service Page between degrees Celsius and degrees Fahrenheit. The selected units are colored blue and to change between Celsius and Fahrenheit, press the button.

Information Page

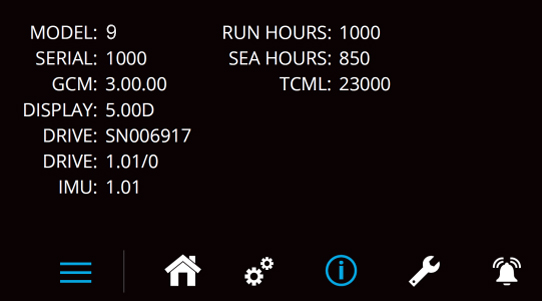

- The Information Page

displays the Seakeeper Model, Serial Number, Software Versions, Run Hours, Sea Hours, and other information. The image below is an example and may not match information details of installed Seakeeper.

displays the Seakeeper Model, Serial Number, Software Versions, Run Hours, Sea Hours, and other information. The image below is an example and may not match information details of installed Seakeeper.

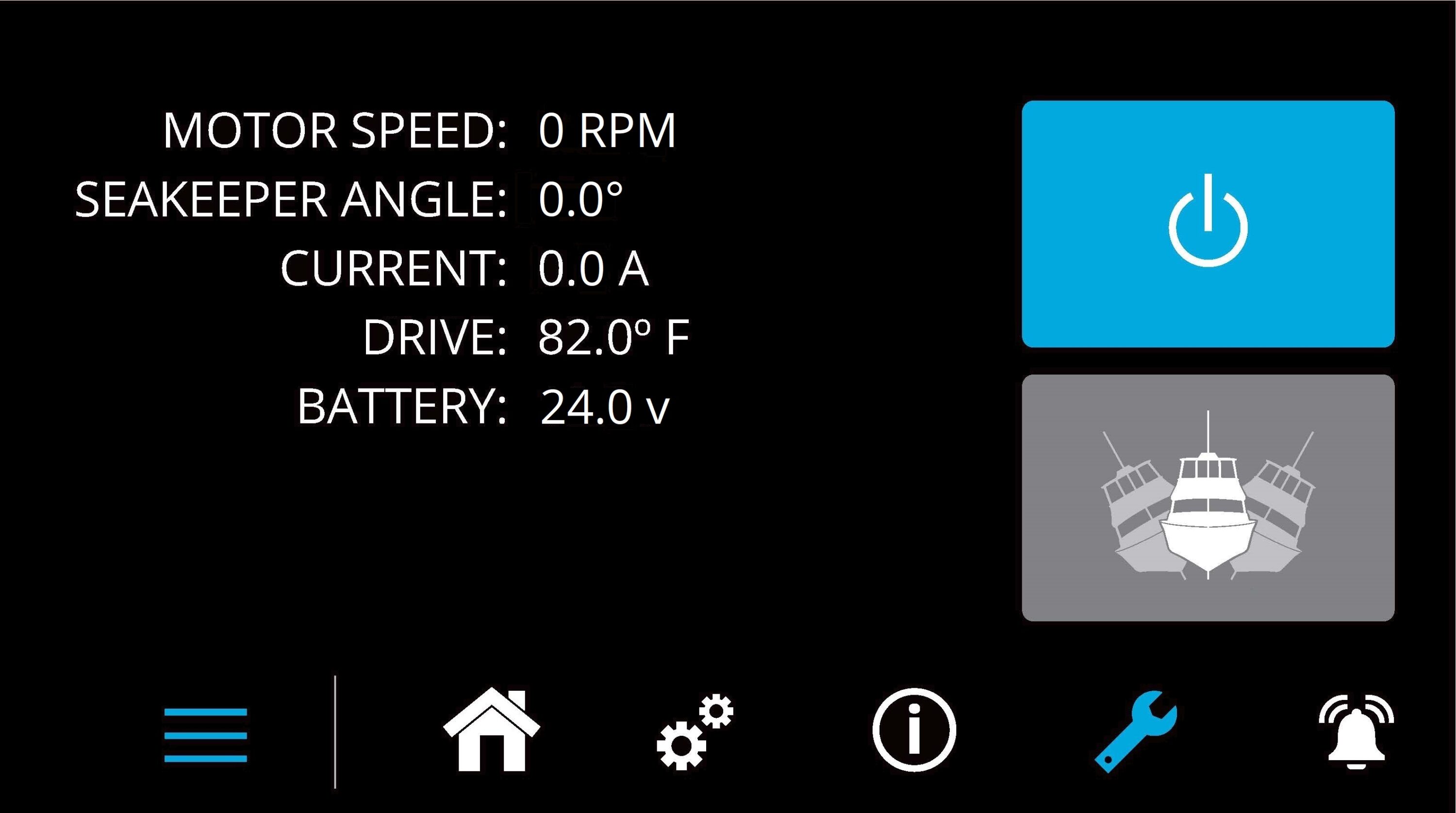

Service Page

- The Service Page

displays Seakeeper operating information.

displays Seakeeper operating information.

Alarm History Page

- The Alarm History Page

shows alarms and warnings that have occurred in the past and their associated run hours. The scroll bar on the right is used to move up and down through the list.

shows alarms and warnings that have occurred in the past and their associated run hours. The scroll bar on the right is used to move up and down through the list.

3.2 Operating Instructions

Start Up Instructions

- Make sure AC and DC power are available.

- Turn on the boat’s DC circuit breaker that supplies power to the Seakeeper.

- Turn on the boat’s AC circuit breaker that supplies power to the Seakeeper.

- In most cases, the seawater pump will be wired to turn on when the Seakeeper is turned on. However, in some cases the seawater pump is on a separate AC or DC circuit breaker and it is necessary to turn it on.

- When the DC power is turned on, the Display will initialize and the Home Screen will appear. If a fault is present an Alarm Screen will appear.

- To turn the Seakeeper on, press the On/Off button, the button will turn blue. The progress bar will appear and indicate how soon the Seakeeper will be available for stabilization. When the Seakeeper is initialized and up to minimum operating speed the Stabilize button will appear. At this point, the Seakeeper is available for stabilization.

- The progress bar indicating flywheel spool-up will disappear from the display screen once the STABILIZE button is pressed (turns blue) and the ConnectBox will fully illuminate. At this point, the Seakeeper has reached its rated operating RPM and maximum stabilization is available. If the STABILZE button has not been pressed(button is grey), pressing the button will turn it blue and stabilization will be provided. The seawater pump will cycle on and off based on the operating temperature of the Seakeeper 9.

Stabilization Instructions

Boat operators are advised that the Seakeeper’s sole function is to dampen a boat’s cyclic roll motions. The Seakeeper is not, and is not intended to be, a substitute for adequate hull stability about the pitch, roll and yaw axes and the Seakeeper is not designed to prevent any instability due to improper boat operation, including, without limitation, any aggressive maneuvers at high speed. During aggressive maneuvers at high speed, the Seakeeper outputs a constant pitch moment which can create a small bow-down or bow-up trim change.

Improper boat operation including, without limitation, aggressive maneuvers at high speed can result in the boat becoming unstable. If you intend to operate the boat in such a manner, you should lock the Seakeeper in the vertical position before operating the boat in that manner. This is easily accomplished by turning the boat to starboard at slow speed in the Stabilize mode. After turning to starboard for 5 seconds, turn the Stabilize mode off while continuing to turn and then go to the Service Page on the display and confirm the Gyro Angle is within +10 degrees of 0 degrees.

To stabilize the vessel after the Seakeeper is On and the flywheel is above the minimum stabilization RPM:

- Press the Stabilize button. The button will turn blue indicating that the Seakeeper is stabilizing the roll motion.

If it is necessary to shut off power to the flywheel motor and slow the flywheel for any reason, press Seakeeper On/Off button; the button will turn grey and the Stabilize button will disappear, indicating the command has been accepted. It takes approximately 4+ hours for the speed to slow down to 0 RPM.

_________________________________________________________________________________________

If it is necessary to stop Seakeeper motion for any reason, press the Stabilize button. The Stabilize button will turn grey indicating that the Seakeeper is locked. Never attempt to work on the Seakeeper until the flywheel has stopped spinning. In the event that the brake system has automatically locked the Seakeeper due to an alarm or failure, no attempt should be made to bypass the alarm or automatic lock.

Speed Adjustment

- Press the Menu button

, then select the Settings screen

, then select the Settings screen  .

. - Select the desired RPM button to adjust the Seakeeper’s speed. The selected RPM button will turn blue. Speed selection buttons shown below are examples and may not match operating speed of installed Seakeeper.

Seakeeper 9: Normal operational speed is 9000 RPM. Quiet mode operates at 7200 RPM, which allows stabilization at a reduced flywheel speed. After a 24 V power cycle to the Seakeeper, the speed selection will revert to 9000 RPM.

Normal Shutdown Instructions

The Seakeeper should be stopped when pulling into port and stabilization is no longer required. This maximizes life by allowing the Seakeeper to start the coast down cycle before cooling is shutoff. Once the vessel is secured, the AC and DC breakers can be switched Off. The Seakeeper will continue to spool down to 0 RPM. No cooling is required during this time.

- Press the Seakeeper On/Off button. The On/Off button will turn grey. The Seakeeper will discontinue stabilization and the flywheel will start coasting.

- Once the vessel is secured in the slip and the crew has shut down the generator and engines, switch the AC and DC breakers that control the Seakeeper Off. The flywheel will continue to spool down to 0 RPM. This can take 4+ hours from full speed. When the flywheel has stopped spinning, 0 RPM will appear on the screen.

The circuit breakers should be left on as long as possible while the Seakeeper is spinning to remove heat from the Seakeeper. During normal operation, the Seakeeper should be stopped when pulling into port and stabilization is no longer required. This maximizes long term life as it allows the Seakeeper to start the coast down cycle before cooling is shutoff. Once the vessel is secured in the slip and the crew has shut down the generator and engines, the AC and DC breakers that control the Seakeeper should be switched to the Off position. The Seakeeper will continue to spool down to 0 RPM. No cooling is required during this time. Note Seakeeper will take approximately 4+ hours to coast down to 0 RPM from full speed. The Display will indicate 0 RPM when the flywheel has stopped.

Note: The seawater pump may run for up to 5 minutes after the Seakeeper is switched off and is coasting (with DC Seawater Pump power applied).

4.0 Power Failures, Alarms, and Troubleshooting

4.1 Power Failures and Alarms Introduction

The Motor Drive Box contains hazardous voltage and the cover should not be removed while the flywheel is spinning and the AC input voltage is present. This high voltage exists even if the flywheel is coasting down and the supply voltage has been shut off. The flywheel must be at 0 RPM and AC input power disconnected for at least 10 minutes prior to any service work on the motor drive box.

____________________________________________________________________________________________

The operator should physically examine the Seakeeper following an alarm. Continuing to reset alarms without service intervention can result in damage or personnel injury.

____________________________________________________________________________________________

The flywheel must be at Zero (0) RPM and AC input power disconnected for at least 10 minutes prior to any service work on the Seakeeper.

The Seakeeper 9 has safety features, such as alarms and warnings, that pop-up on the Seakeeper

Application and are signaled on the ConnectBox to protect the Seakeeper as well as the vessel. The brake can be locked from the Application, ConnectBox or by shutting off power at the supply breakers, preventing the Seakeeper from precessing.

In the event of a DC control power failure, the brake automatically locks the Seakeeper so it cannot generate anti-rolling torque loads.

There are three sources of power to the Seakeeper 9:

- 24 VDC powers the Seakeeper for all the control electronics.

- 24 VDC powers the DC Seawater Pump for cooling water supply.

- 208 – 230 VAC powers the Motor Drive Box to drive the motor inside the Seakeeper.

These are supplied on cables shown on Drawing No. 90257 – Seakeeper 9 Cable Block Diagram.

4.2 DC Power Failure

24 VDC Control Power

If the 24 VDC is disconnected during operation, the display will be blank, flywheel speed will decrease, and the brake will be locked (no precession).

- Verify the boat’s circuit breaker supplying +24 VDC has not tripped and the AC breaker is On.

- When +24 VDC is restored, the display will power up, the Splash Screen will appear, and then the Home Screen will appear.

- Press Power On/Off button

. The progress bar will appear and indicate flywheel speed. When the flywheel is at minimum operating speed, the Stabilize button will appear so stabilization can be turned on. This may take up to 30 minutes, depending on the speed of the flywheel when the +24 VDC is turned back on.

. The progress bar will appear and indicate flywheel speed. When the flywheel is at minimum operating speed, the Stabilize button will appear so stabilization can be turned on. This may take up to 30 minutes, depending on the speed of the flywheel when the +24 VDC is turned back on.

Seawater Pump Power

If Seawater Pump input DC power is disconnected during operation, the Seawater Pump will fail to provide cooling seawater flow when required. The resulting high temperatures would result in the Seakeeper being turned off (no stabilization) due to high temperature alarm(s).

- Verify the boat’s circuit breaker or fuse supplying DC Seawater Pump power has not tripped or blown.

- When DC SW Pump power is restored, reset any alarm and continue Seakeeper operation.

4.3 230 VAC Failure

AC Power Failure

If the AC power is not connected, a notification screen will indicate “AC Mains Low”. If the failure is not corrected within two minutes, an “AC Mains Low” alarm will occur. The brake will lock and the Seakeeper will stop moving if stabilization was on.

- Verify the boat’s circuit breaker supplying 208-230 VAC to the Motor Drive Box has not tripped.

- When 208-230 VAC is restored, the display will power up, the Splash Screen will appear, and then the Home Screen will appear.

- Press Power On/Off button

to clear the alarm. The progress bar will appear and indicate flywheel speed. When the flywheel is at minimum operating speed, the Stabilize button will appear so stabilization can be turned on. This may take up to 30 minutes, depending on the speed of the flywheel when the 208-230 VAC is turned back on.

to clear the alarm. The progress bar will appear and indicate flywheel speed. When the flywheel is at minimum operating speed, the Stabilize button will appear so stabilization can be turned on. This may take up to 30 minutes, depending on the speed of the flywheel when the 208-230 VAC is turned back on.

AC Power Fluctuation, Spike, or Momentary Failure

If the AC voltage to the Motor Drive Box is outside Seakeeper’s specified range (208 – 230 VAC), the Motor Drive Box will briefly shut down for protection. The Motor Drive Box will continue operation when the voltage returns to the specified range.

A brief fluctuation can happen when the generator is unable to regulate its output voltage, particularly when a large AC load is switched on or off. A momentary AC failure also happens during transition from shore power to ship’s power.

4.4 Alarms and Troubleshooting

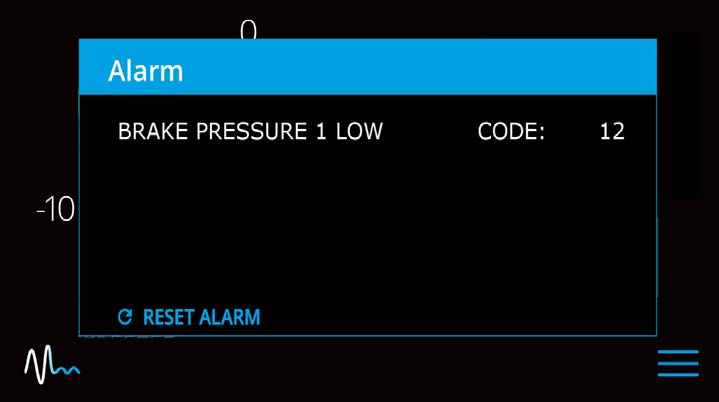

Alarms

The operator should physically examine the Seakeeper following an alarm. Continuing to reset without service intervention can result in damage or personnel injury.

Sensors, alarms, and shutdowns are provided to allow unattended operation. Sensors measure drive temperatures, gimbal angle, brake pressure, and vessel motion. The Seakeeper controller sends sensor values and alarm information to the display and locks the brake and shuts down the motor drive in the event of an alarm condition. Seakeeper operating history during faults or alarms is recorded in the controller’s memory for subsequent recall if service is needed. Seakeeper and Seakeeper Dealers may access the Seakeeper’s software to gather run hours, bearing loading, and hull slamming information.

NOTE: Only the MFD app or the Seakeeper 5” Touch Display can identify and address the alarm. The alarm will not clear until the operator presses the Reset Alarm button, AND the alarm condition is no longer present. The operator can then press the POWER button again to resume Seakeeper operation.

- A view of a typical Alarm screen.

- To reset the alarm, press the Reset Alarm button:

Troubleshooting

- At MFD app or 5″ Touch Display, check for alarms or warnings.

- Power Supply: Check electrical power source breakers ON or fuses installed and NOT blown.

- Mechanical Components:

- For temperature -related alarm, verify the coolant reservoir is filled with glycol mixture (50% ethylene glycol/50% distilled water). Verify seawater pump power aligned.

- Visually check mechanical fittings and joints for leakage.

- Visually check coolant and brake hoses for chaffing and leakage.

- Contact an authorized Seakeeper dealer for further assistance in diagnosing and resolving complex alarms.

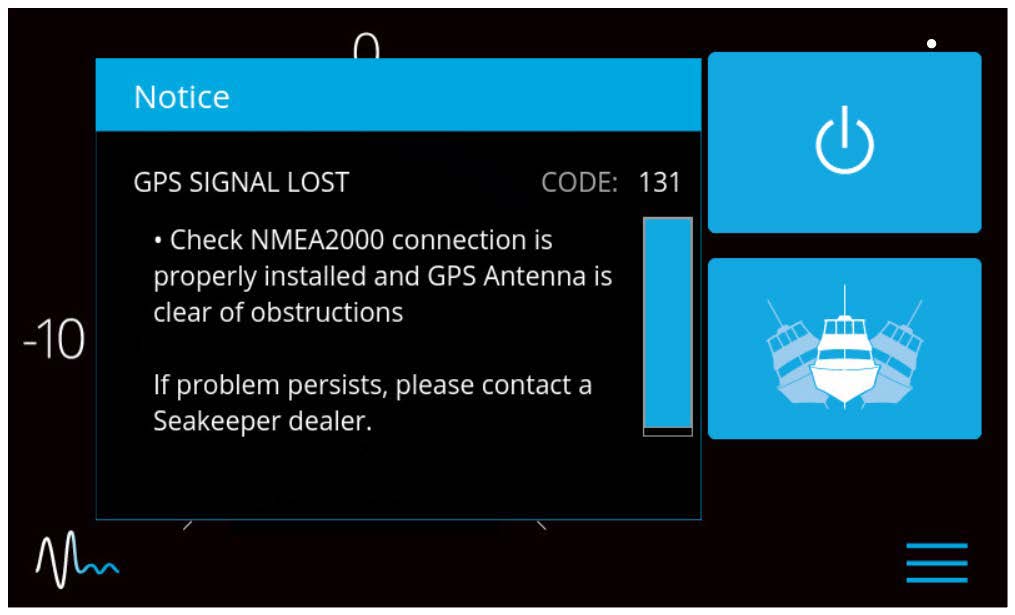

If a GPS signal is lost, a warning message will appear in the Alarm History and a message will appear on the Home Screen, as seen below. The Seakeeper will not spool down, however the precession rate and angle of the sphere will be reduced until GPS signal returns.

4.5 Alarm History

The operator should physically examine the Seakeeper following an alarm. Continuing to reset alarms without service intervention can result in damage or personnel injury.

The ALARM HISTORY page on the Seakeeper application or display shows the recent alarms and warnings. Alarms trigger a pop-up message to be displayed on the display or Seakeeper App. Warnings will be listed in the alarm history but do not affect Seakeeper operation. The alarms and warnings are in chronological order starting with the most recent. Warnings included in the history page are for issues that do not affect gyrostabilizer operation.

Press the Menu button ![]() to show the page options and then the Alarm button

to show the page options and then the Alarm button ![]() to show alarm history.

to show alarm history.

5.0 Maintenance

5.1 Maintenance Introduction

The Seakeeper system is designed to require as little maintenance as possible. However, since the system is comprised of mechanical and electrical components that operate in a marine environment, some periodic inspections and maintenance are required. Seakeeper recommends a regular inspection interval and Scheduled Maintenance to keep the Seakeeper running trouble-free.

If the Seakeeper is installed in a wet space, efforts should be made to keep the Seakeeper free of salt residue from either condensation or direct exposure to salt spray. If exposed, a regular wipe down with mild soap and water with a rinse will help limit corrosion and keep the Seakeeper assembly in good cosmetic condition. Refer to How to Care for Your Seakeeper article for details.

If any components of the Seakeeper or its sub-systems will be exposed to environmental temperatures where winterization is necessary for storage, reference How Do I Winterize My Seakeeper article for details.

The Seakeeper comes standard with sealant and thread locker on applicable fasteners. When reinstalling all fasteners use thread locker and sealant unless otherwise specified.

Reference Documents:

Due to remote start capabilities of MFDs, ENSURE power removed from Seakeeper and flywheel at zero RPM at display/MFD app before removing covers.

Hydraulic Hand Pump Kit is required for servicing the brake. Pressure should NOT be relieved unless this tool is available.

5.2 Scheduled Maintenance Table

The following contains the scheduled maintenance table organized by RUN hours. Scheduled maintenance is not covered under warranty.

*These tasks must be performed by a certified Seakeeper Dealer.

Find a local Dealer at www.seakeeper.com/find-us

Perform the Recommended Maintenance after the indicated number of Running [RUN] hours or Years since last maintenance, whichever occurs first.

Seakeepers are designed for use in a marine environment and to withstand occasional water spray or splash. Prolonged exposure to seawater, however, can cause premature wear and damage to the unit; therefore, it is important to apply a gentle fresh water rinse following exposure to seawater.

The service intervals are based on ‘average’ use, including operating in various Sea conditions, such as zero or low-speed usage in/around marinas and anchorages vs. different speeds while underway in light or heavy sea conditions. If the customer’s normal operating conditions include extended SEA operation, more frequent service should be considered.

6.0 Warranty and Limit of Liability

6.1 Warranty

The complete Seakeeper warranty details may be found on the Seakeeper website www.seakeeper.com.

Register your Seakeeper at the Seakeeper Warranty Registration page.

Seakeeper Standard Models

This warranty starts upon the installation of the Product, and the warranty period is for the shorter of the following periods:

- Twenty-four (24) months from purchase date of a vessel on which the Product is installed;

- Twenty-four (24) months from date the Product is installed on an existing vessel (refit); or

- Two thousand (2000) operating SEA hours, subject to verification and confirmation by SEAKEEPER.

Exclusions

Any installation, repair or any handling of the Product shall be done only by an authorized person trained and explicitly authorized in writing by SEAKEEPER.

This warranty shall be void and not apply to or resulting from:

- ANY UNAUTHORIZED MODIFICATION OF THE PRODUCTS AS SHIPPED WILL RESULT IN VOIDING THIS WARRANTY.

- An application or installation method not approved by Seller, including improper or inadequate site preparation, faulty installation, handling during maintenance or otherwise, if any, by the Customer, as well as to defects attributable to loading/shipment/delivery of the Product or any other defect or damage not attributable to SEAKEEPER.

- Defects resulting from Customer’s or any third-party interface of equipment, hardware or software if installed, connected, or loaded into and/or onto the Product.

- Misuse, operator error or fault caused by the failure of an external unit (i.e., Sea Water pump, Ships power supply).

- Any negligent or willful misconduct.

- Excessive exposure to water (salt or fresh) including submersion (partial or full).

- Acts of Nature such as, but not limited to, fire, flood, wind, and lightning.

- Improper use or operation of the vessel.

- Failure of the Customer to strictly comply with any of the following requirements:

- Operation and Maintenance according to the guidelines and recommendations specified in the SEAKEEPER Operation Manual.

- Proof of such compliance shall be provided upon request.

- Operation and Maintenance according to the guidelines and recommendations specified in the SEAKEEPER Operation Manual.

Warranty Activation

A Warranty Registration must be fully completed and sent to SEAKEEPER for review, approval and registration upon delivery of the vessel to the first retail Customer. Warranty registration and expiration date confirmation can be achieved by providing SEAKEEPER, a copy of the original bill of sale, purchase agreement, Customer’s name, address and SEAKEEPER Product Serial Number along with current RUN / SEA hours to SEAKEEPER’s warranty registration department within thirty (30) days of purchase.

For removal of doubt, it is clarified that the activation date shall in no event affect the warranty period set forth herein.

6.2 Limitation of Liability

NOTWITHSTANDING ANYTHING CONTAINED HEREIN TO THE CONTRARY, SEAKEEPER, INC., SHALL NOT BE LIABLE FOR ANY SPECIAL, PUNITIVE, INCIDENTAL, INDIRECT OR CONSEQUENTIAL DAMAGES INCLUDING, BUT NOT LIMITED TO, LOST PROFITS, ARISING OUT OF THE PERFORMANCE, DELAYED PERFORMANCE OR BREACH OF PERFORMANCE OF THIS ORDER REGARDLESS OF WHETHER SUCH LIABILITY IS CLAIMED IN CONTRACT, EQUITY, TORT OR OTHERWISE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. SEAKEEPER’S OBLIGATION IS LIMITED SOLELY TO REPAIRING OR REPLACING (AT ITS OPTION AND ONLY AS SET FORTH HEREIN), AT ITS APPROVED REPAIR FACILITY, ANY GOODS OR PARTS WHICH PROVE TO SEAKEEPER’S SATISFACTION TO BE DEFECTIVE AS A RESULT OF DEFECTIVE MATERIALS OR WORKMANSHIP, IN ACCORDANCE WITH SEAKEEPER, INC.’S STATED WARRANTY. IN NO EVENT SHALL SEAKEEPER’S CUMULATIVE LIABILITY EXCEED THE TOTAL PURCHASE PRICE SETFORTH IN THIS ORDER. CUSTOMER HOLDS HARMLESS SEAKEEPER AND INDEMNIFIES SEAKEEPER FOR ANY ACT OR OMISSION TO ACT THAT VOIDS THE LIMITED WARRANTY OR OTHERWISE BREACHES CUSTOMER’S OBLIGATIONS PURSUANT TO THE TERMS AND CONDITIONS OF SALE.

The terms and conditions of this warranty are the entire agreement between the Parties relating to the warranty obligations of SEAKEEPER to the Products. There are no other express or implied terms or conditions of this warranty.

7.0 Specifications and Summary

| Seakeeper 9 | |

|---|---|

| Rated RPM | 9,000 RPM |

| Angular Momentum at Rated RPM | 9,000 N-m-s |

| Anti-Rolling Torque at Rated RPM | 18,890 N-m |

| Spool-up Time to Rated Speed | 55 minutes (9,000 RPM) |

| Spool-up Time to Stabilization | 38 minutes (7,650 RPM) |

| Spool-up Power AC Motor DC Control | 3,000 Watts Max 240 Watts |

| Operating Power AC Motor (Sea state dependent) DC Control | 1,000-2,000 Watts 240 Watts |

| Voltage AC Input DC Input | 208-230 VAC, 50/60 Hz, Single Phase 24 VDC @ 10 Amps |

| Seawater Supply to Heat Exchanger | 4 GPM (15.1 LPM) minimum 8 GPM (30.3 LPM) maximum |

| Ambient Air Temperature | 32˚ – 140˚F (0 – 60˚C) |

| Weight | 1,250 lbs (567 kg) bolt-in |

| Envelope Dimensions | 33.8 L x 35.7 W x 27.6 H (inches) 0.86 L x 0.91 W x 0.71 H (meters) |

| Noise Output | At full operating RPM, steady state noise measured in the factory at a 1-meter distance measures 68-70 dBC (sound levels may be higher during spool-up). |

Arrangement

The Seakeeper 9 consists of the Flywheel, Enclosure, Foundation, Electronics, Brake, Cooling, and Cover Subsystems.

Installation Location

The Seakeeper is a torque device and does not have to be installed in a specific hull location or on the centerline. However, the Seakeeper should not be installed forward of the longitudinal center of gravity to minimize high acceleration loading due to hull/wave impacts during operation at high speed or in large waves.

Mounting Dimensions

See Drawing No. 90225 – Seakeeper 9/7HD Bolt-In Installation Details.

See Drawing No. 90226 – Seakeeper 9/7HD Bond-In Installation Details.

Loads

The installer is responsible for designing the foundation to which the Seakeeper is attached and for ensuring that this foundation can safely transfer the concentrated Seakeeper loads from the frame to the adjacent hull structure. Loads that the Seakeeper imposes on the hull structure are explained on Drawing No. 90225 – Seakeeper 9/7HD Bolt-In Installation Details and Drawing No. 90226 – Seakeeper 9/7HD Bond-In Installation Details; these loads do NOT include vessel motion accelerations, such as vertical slam loads which can be high for higher speed vessels.

Cooling

The Seakeeper bearings, Motor Drive Box, and hydraulic manifold are cooled by a closed water / glycol mix cooling loop that incorporates a seawater heat exchanger. The installer is responsible for providing 4 – 8 GPM (15.1 – 30.3 LPM) raw water at ambient sea temperature and a maximum pressure of 20 psi (1.4 bar) to the heat exchanger.

Electrical

The installer is responsible for supplying 208-230 VAC, 50/60 Hz, single phase power on a 20 A service to the Motor Drive Box and 24 VDC at 10 A service to the Seakeeper Control System. Separate circuit breakers should be used for each Motor Drive Box in multiple Seakeeper installations. Similarly, separate circuit breakers should be used for each Seakeeper Control System in multiple Seakeeper installations.

Operator Controls

A Display with integrated Keypad is used to start, operate, monitor, and shutdown the Seakeeper.

Performance

Reduction of boat roll is a function of the boat’s displacement, transverse metacentric height (GMT) and hull damping as well as the operating conditions (speed and heading with respect to waves) and sea state. The Seakeeper controller regulates the active hydraulic brake to ensure the Seakeeper’s anti-roll torque is maximized regardless of hull characteristics or operating conditions.

Alarm and Monitoring

Sensors, alarms and shutdowns are provided to allow unattended operation. Sensors measure Seakeeper and drive temperatures, vacuum pressure, gimbal angle, brake pressure, and ship motion. The Seakeeper controller sends sensor values and alarm information to the display and also locks the brake and shuts down the motor drive in the event of an alarm condition. Seakeeper operating history during faults or alarms is recorded in the controller’s memory for subsequent recall if service is needed. Seakeeper may access the Seakeeper’s software to gather run hours, bearing loading, and hull slamming information.

Safety

The brake automatically locks the Seakeeper so it cannot generate excessive anti-rolling torque loads in the event of a system fault or alarm, loss of electrical power or loss of brake pressure. The brake can be locked from the Display or by shutting off AC and DC power at the supply breakers.

8.0 Revision History

| REVISION | DESCRITION | DATE |

| 5 | Minor edits throughout. | 01JUN2015 |

| 6 | 7HD model introduced. Minor edits. | 26JAN2017 |

| 7 | 5″ Touch Display introduced. | 20OCT2017 |

| 8 | Corrections and edits. | 03SEP2021 |

| 9 | Deleted 7HD model references. Updated specifications for FRB model. | 08MAR2023 |

| 10 | ConnectBox user interface introduced. Scheduled maintenance table updated to match latest TB-90426 revision. | 25SEP2023 |