Seakeeper 5 / 6 Installation Manual (90402-4) 6/5-222-5365 to 6/5-233-5846

2.2 Selection of Installation Location

Seakeeper can only assess installation location regarding its impact on Seakeeper operation and serviceability. Seakeeper cannot determine how the installation location will affect the vessel static or directional stability other than cyclic roll reduction. The Installer is responsible for considering the Seakeeper‘s effect on the CG location, trim, overall stability, and performance of the vessel.

Selection of mounting location of Seakeeper should consider the following desirable features:

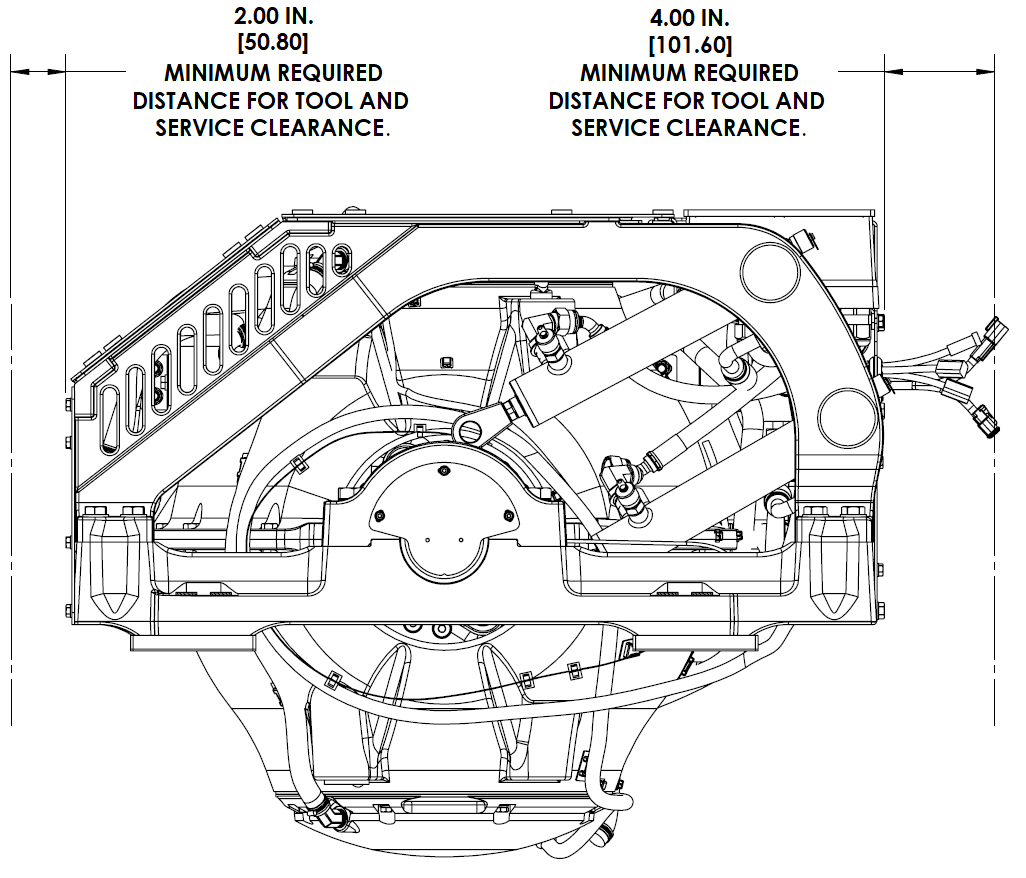

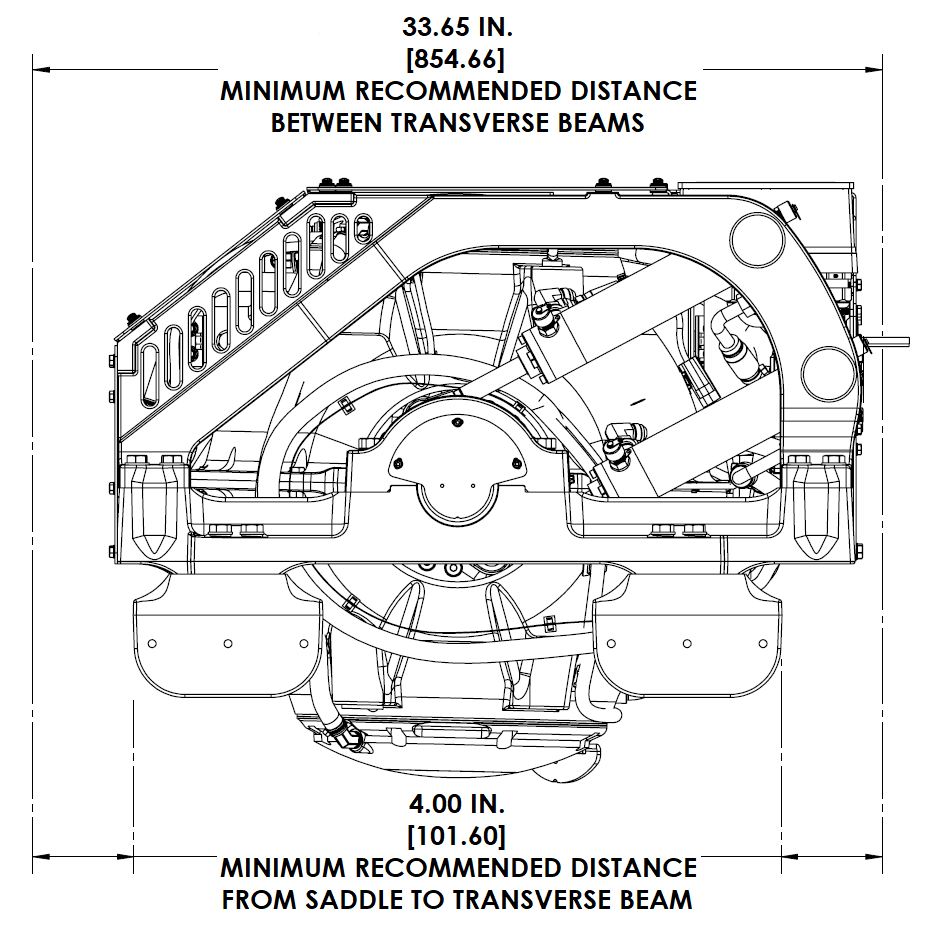

- Overhead access or sufficient clearance for removal / re-installation of the Seakeeper for overhaul in future years. Provide adequate clearance for maintenance, as shown in Figure 1 and 2 below.

- The Seakeeper should be installed in a dry space to minimize effects of corrosion.

- Installed near vessel’s longitudinal center of gravity (LCG) to minimize effects on trim and performance in various loading conditions.

VIEWS SHOWING RECOMMENDED CLEARANCES AROUND THE SEAKEEPER FOR USE OF HANDTOOLS, EASE OF MAINTENANCE, INSTALLATION, AND PROPER OPERATION.

Figure 1 – Seakeeper 6 Installed Clearance Considerations

Refer to Figure 2 for recommended clearances to transverse beams. If a transverse beam is located under the forward brace, it must be 4 in. (102 mm) from the edge of the saddle beams to provide the necessary clearance for the swing of the motor power cable during precession. Clearances aft of the Seakeeper are shown to provide access for maintenance.

2.2.1 Noise/Soundproofing

Seakeeper noise has been measured under steady state conditions (no wave load) in Seakeeper‘s Engineering Lab and in our Factory Demo Boat. The steady state noise is typically <72 dBC at 1 meter. As the frequencies emitting the highest sound pressures are low (like other marine machinery), it is recommended that the Seakeeper be installed in a machinery space that is already treated with soundproofing.