Seakeeper 40 Installation Manual (90715-2) 40-234-0043 to Current

2.3 Selection of Installation Method

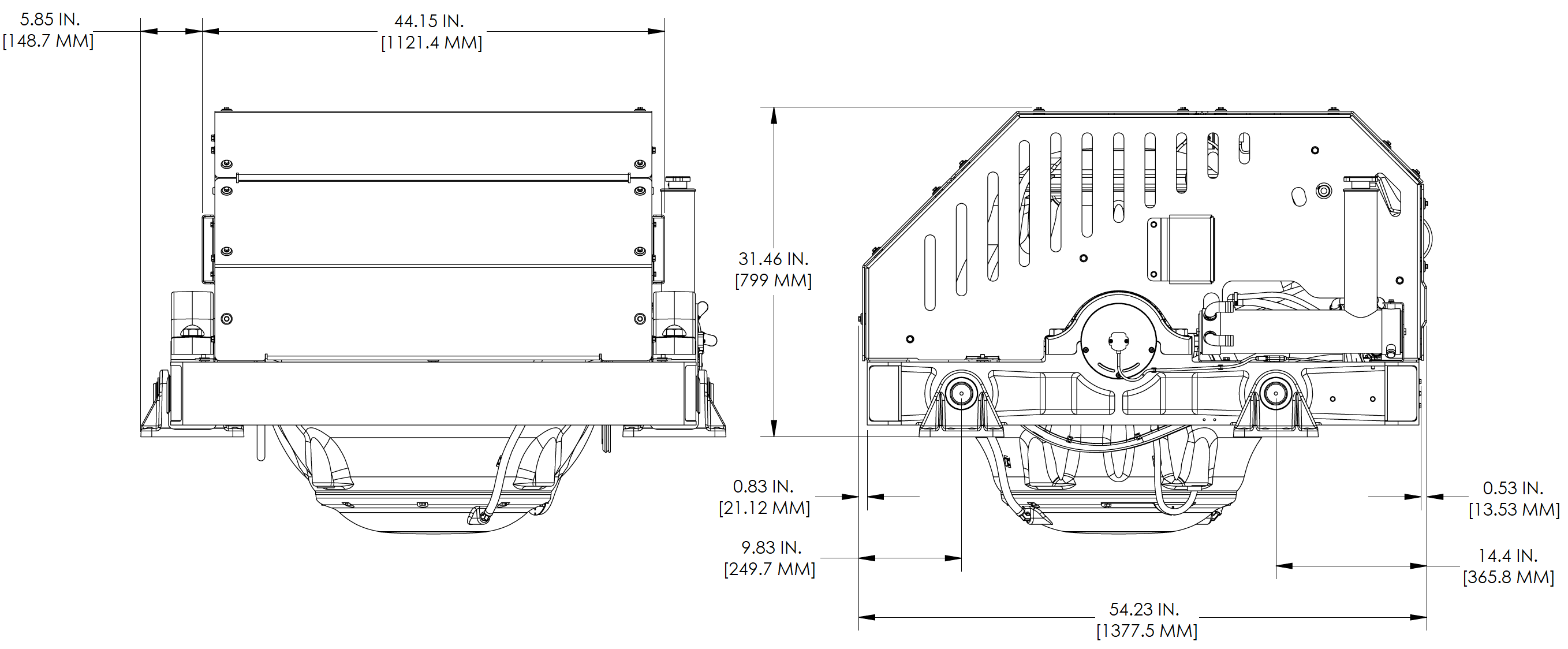

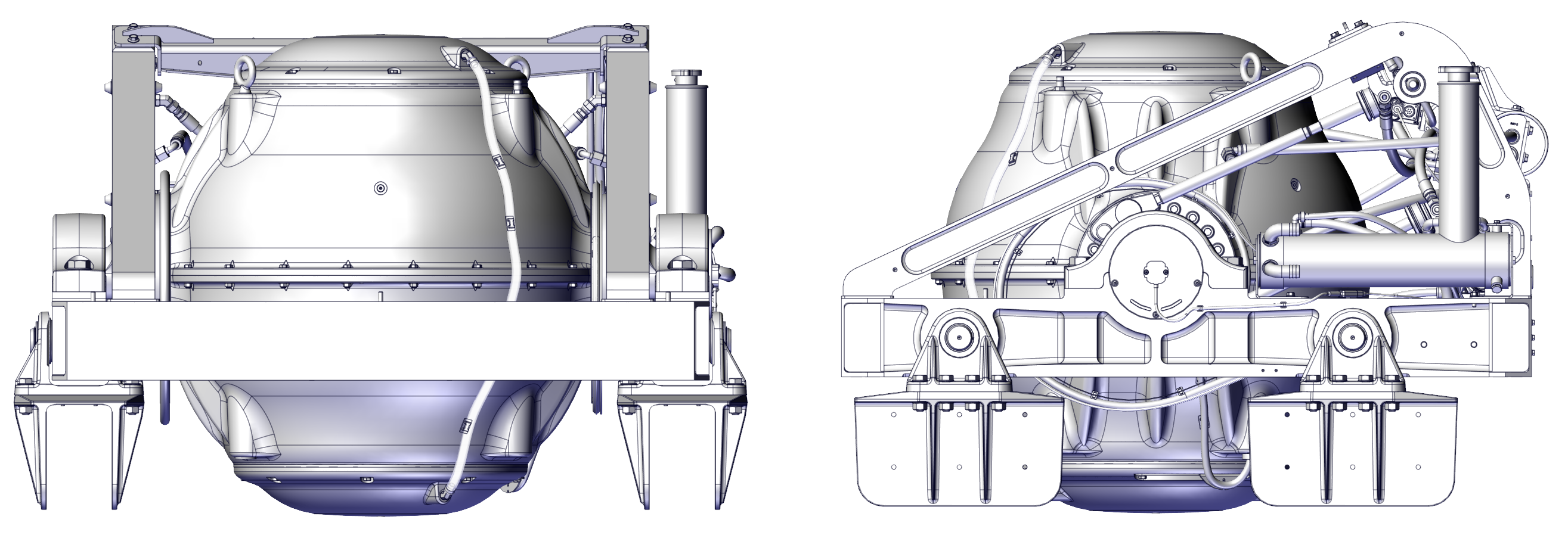

The Seakeeper 40 FRB can be affixed to the hull structure using two methods 1) Bolt-In installation or 2) Bond-In (Saddle) installation. See figures below.

Option 1 would be applied when a metal structure or laminated metal plates are available for attachment. The foundation would fasten directly to the hull structure or plates using isolation gaskets for metal-to-metal contact using 32 x M16-1.0 fasteners. Depending on the structure to which the Seakeeper is fastened, blind threaded holes (Seakeeper Part No. 90614) or thru-bolting (Seakeeper Part No. 90086) can be utilized.

Option 2 would be commonly used on a hull constructed of glass-reinforced plastic (GRP) or fiberglass. For this option, four 16.0 in. (406 mm) long by 8.0 in. (203 mm) deep saddles (Seakeeper Part No. 90287) are bonded to properly spaced and prepared structural members that are an integral part of the hull structure. Seakeeper recommends using a structural adhesive with a lap shear strength of 2000 psi (13.8 MPa) or greater, such as Plexus MA590. Careful consideration should be exercised by the installer while selecting the appropriate adhesive. Compatibility with the Seakeeper’s cast aluminum A356-T6 saddles, hull structure, and pot life are three critical factors. Proper surface preparation per the adhesive manufacturer’s recommendations before installation is required.

Note: If bonding saddles to a metal structure, contact Seakeeper for hull preparation instructions.