Seakeeper 4 / 4.5 Installation Manual (90762-1)

1.0 Introduction

Seakeeper 4 / 4.5

Installation Manual

90762, revision 1

This installation manual is intended to provide details and guidance to a boat builder

or equipment installer to install the Seakeeper 4 and Seakeeper 4.5 Stabilization Systems

(Serial number 4-0001 and 4.5-0001 to current).

Reference Documents:

- 90737 – Seakeeper 4.5 Hardware Scope of Supply

- 90807 – Seakeeper 4 Packing List

- 90806 – Seakeeper 4.5 Packing List

1.1 Precautions

There is a significant torque about the gimbal axis when the

Seakeeper is precessing. Seakeeper cover panels are provided to prevent personnel or equipment from contacting the Seakeeper while in operation. These covers should not be stepped on or have anything placed on top. The covers should always be in place during operation.

__________________________________________________________________________________________

If it is ever necessary to access the Seakeeper while the flywheel is pinning, the Seakeeper must be locked at the display to stop the Seakeeper from precessing.

__________________________________________________________________________________________

Stand clear of the Seakeeper and all moving components.

__________________________________________________________________________________________

The unit may be started remotely. Assume it could move without warning.

__________________________________________________________________________________________

The following must be true before accessing the Seakeeper:

* The Input power must be disconnected for at least 10 minutes

* The Seakeeper must be locked (Not in SEA MODE)

* The Flywheel must be at zero speed

- The Seakeeper must only be lifted from the supplied lifting eyes (see Section: Transport and Unpacking).

- Precision bearings support the Seakeeper flywheel. Make sure while unpacking and lifting the Seakeeper assembly NOT to drop or impart mechanical shock as damage to bearings could result.

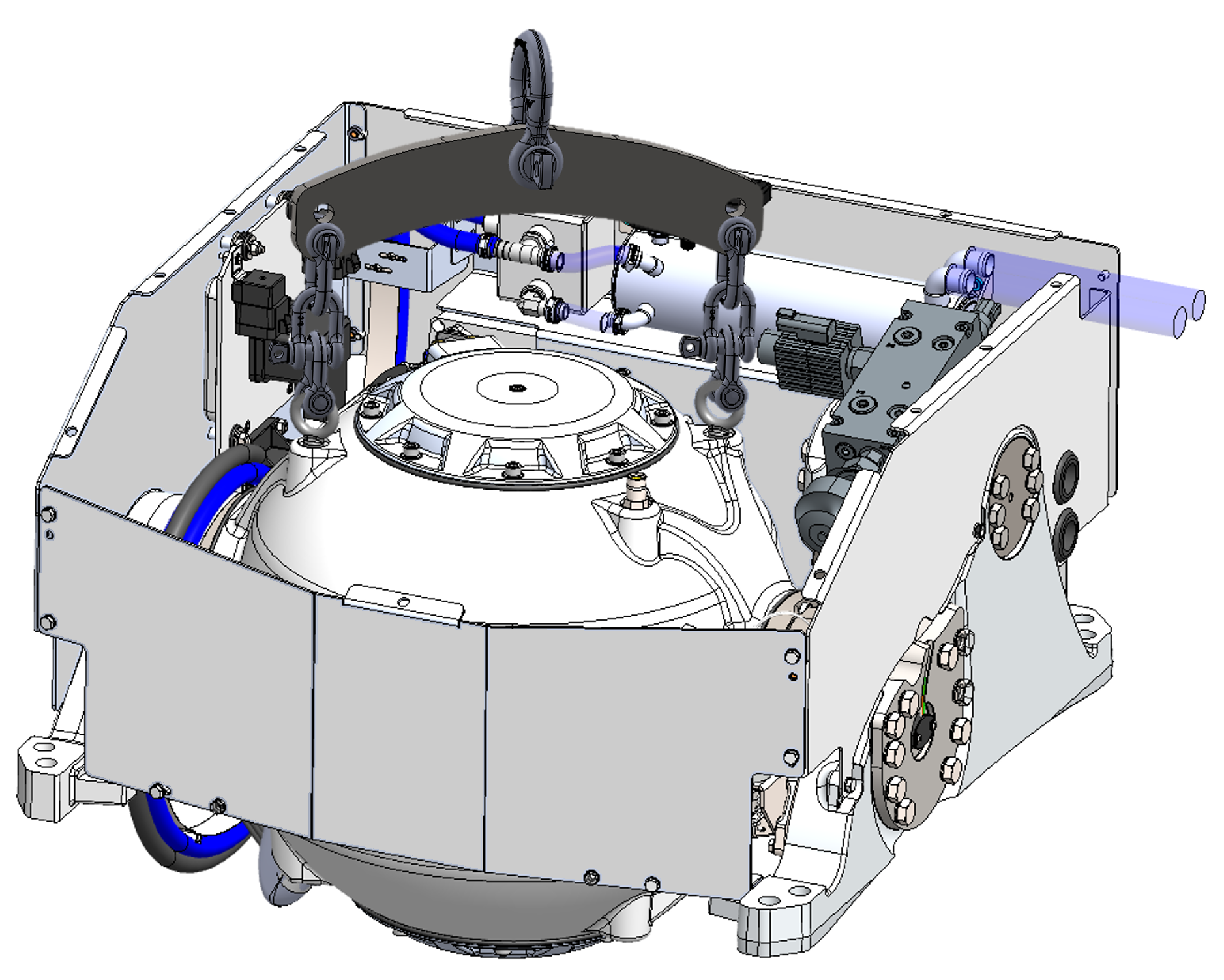

- While handling / installing the Seakeeper assembly, protect exposed hydraulic brake cylinder rods (See Figure 1) from scratches or damage, which could lead to premature seal failure and oil leaks.

- While handling / installing the Seakeeper assembly, do not allow electrical fittings that exit the bottom of the Seakeeper enclosure to contact any surface or object. Damage to the fittings could potentially affect the vacuum integrity of the enclosure.

- Exercise care to protect the painted finish, as damage to the finish could lead to early appearance degradation of the installed Seakeeper.

1.2 Transport and Unpacking

Reference Documents:

- 90808 – Seakeeper 4 & 4.5 Unpacking Instructions

- 90807 – Seakeeper 4 Packing List

- 90806 – Seakeeper 4.5 Packing List

1.2.1 Transport

- Use a Seakeeper provided shipping crate for transport (P/N 90810). Overall dimensions of a fully packed crate are xx.x L X xx.x W X xx.x H in. (x.xx L X xx.x W X xx.x H m) with a weight of xxx lbs (XXX kg).

- Do not stack Seakeeper shipping crates.

- Both Air and Ground transport are acceptable.

- Seakeeper shipping crates must be transported in environmental conditions between 32°F and 140°F (0°C and 60°C).

1.2.2 Unpacking Crate

- Reference Seakeeper Drawing No. 90737 – Seakeeper 4.5 Hardware Scope of Supply for items that ship with the Seakeeper.

- Remove electrical components, cables, and miscellaneous items and set aside.

- Remove packing materials that secure the Seakeeper assembly inside the crate.

- Remove top and angled face cover panels to access lifting eyes.

- Attach spreader bar (P/N 11766) to the two lifting eyes located on the top of the Seakeeper enclosure. Stay clear of any other parts on the Seakeeper. The Seakeeper 4.5 weighs 728 lbs (330 kg).