Seakeeper 40 Installation Manual (90715-1)

2.0 Mechanical Installation

2.1 Mechanical Installation Introduction

The Seakeeper can produce loads up to 11,381 lbs (50.6 kN) at each of the four mounts and careful consideration should be given to foundation design to ensure it can transfer these loads into the hull. These loads do NOT include vessel motion accelerations, such as vertical slam loads which can be significant for high speed vessels. The responsible party for designing the supporting structure (boat builder, installer, or hired sub-contractor) must accommodate the above forces plus a reasonable factor of safety. Seakeeper recommends a minimum safety factor of 3.0 (yielding a Safety Margin of 2.0).” The Seakeeper 40 FRB only supports Bolt-In Installation methods.

It is assumed that the installer is familiar with mechanical fasteners to marine structures and has performed structural analysis to assure the structure to which the Seakeeper mounts, can properly transfer the loads the Seakeeper creates into the hull structure. If the installer has any doubt about the ability of the structure to transfer the loads to the hull, then a licensed naval architect or marine engineer should be contacted to do a structural analysis.

The installer should review the following list of reference drawings to ensure the installation procedure is fully understood.

Reference Documents & Drawings:

2.2 Selection of Installation Location

Selection of mounting location of the Seakeeper should consider the following desirable features:

The Seakeeper should be installed aft of amidships to minimize high acceleration loadings due to hull/wave impacts during operation at high speed or in large waves. If the only possible installation location is forward of amidships, then the installer should have Seakeeper review the installation location prior to finalizing the design.

Seakeeper can only assess installation location regarding its impact on Seakeeper operation and serviceability. Seakeeper cannot determine how the installation location will affect the vessel static or directional stability other than cyclic roll reduction. The Installer is responsible for considering the Seakeeper’s effect on the CG location, trim, overall stability, and performance of the vessel.

The Installer is solely responsible for ensuring that the Seakeeper is properly located and installed on the vessel foundation with an adequate margin of safety for the specified design loads and vessel operating characteristics.

Selection of mounting of the Seakeeper should consider the following desirable features:

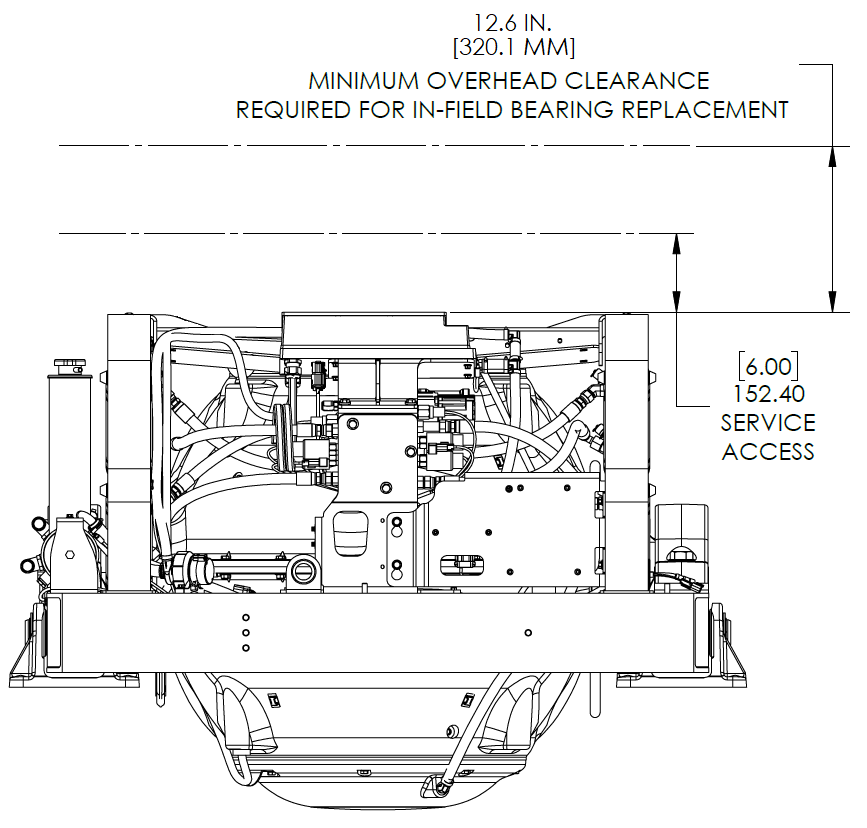

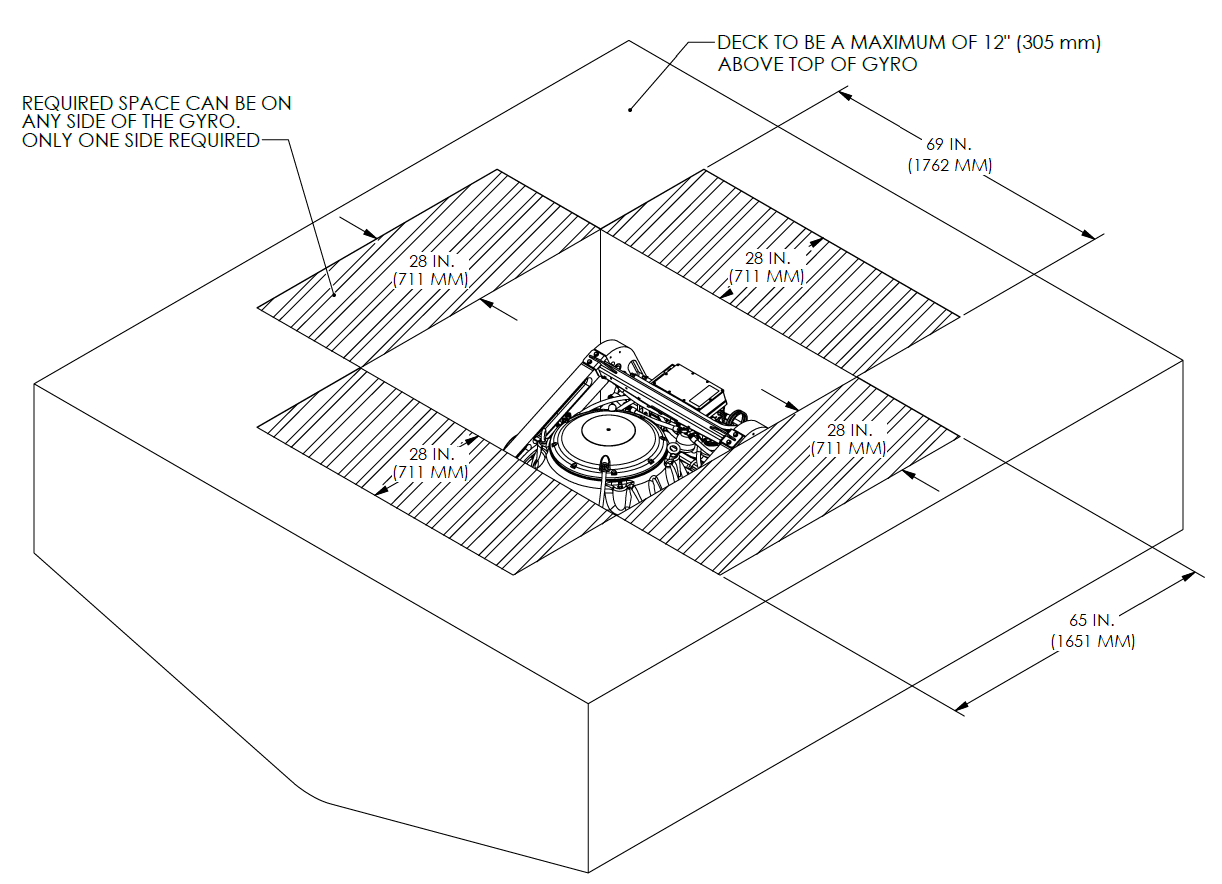

- Overhead access or sufficient clearance for removal / re-installation of the Seakeeper for overhaul in future years per Figure 2.

- The Seakeeper should be installed in a dry space to minimize effects of corrosion.

- Clearance for replacement of gimbal angle sensor on gimbal shaft (see Figure 2).

- Clearance for filling / purging brake hydraulic oil (see Figure 2).

- Clearance for filling water/glycol cooling circuit (see Figure 2).

- Clearance for replacement of brake hydraulic cylinders (see Figure 2).

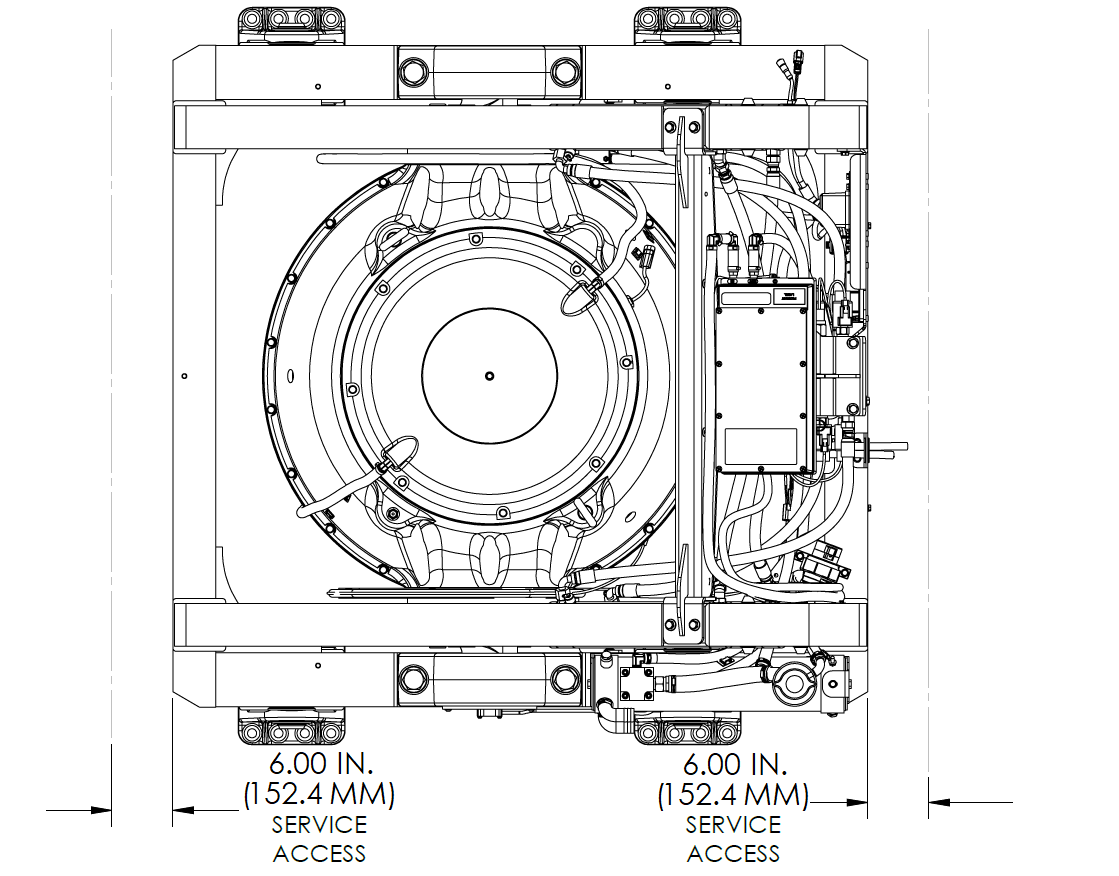

VIEWS SHOWING RECOMMENDED CLEARANCES AROUND THE SEAKEEPER FOR USE OF HANDTOOLS, EASE OF MAINTENANCE, INSTALLATION, AND PROPER OPERATION.

Figure 2 – Seakeeper 40 Installed Clearance Considerations

6 in. (152 mm) on each side with one side having 28 in. (711 mm)

12.6 in. (320 mm) overhead service clearance

2.2.1 Noise/Soundproofing

Seakeeper noise has been measured under steady state conditions (no wave load) in Seakeeper‘s Engineering Lab. The steady state noise is typically < 73 dBC at 1 meter. As the frequencies emitting the highest sound pressures are low (like other marine machinery), it is recommended that the Seakeeper be installed in a machinery space that is already treated with soundproofing.

2.3 Bolt-In Installation

2.3.1 Preparation of Vessel Structure

Seakeeper provided mounting hardware is intended to apply to typical installation arrangements. However, each installation, especially custom aftermarket foundations, should be thoroughly reviewed to ensure the provided hardware meets the required thread engagement for the Seakeeper unit being installed. The mounting bolt thread engagement requirements are outlined in the Installation Manuals and Installation Details Drawings for each Seakeeper model. This also applies to Seakeeper model adapter kits and OEM built frames where the bolt hole depth should be checked to ensure the bolts will not bottom, preventing the bolts from achieving the intended preload.

When the Seakeeper provided hardware is not appropriate, the bolt specification (diameter and thread pitch) and grade should be matched in the required length and used with the Seakeeper provided washers. Mounting bolts should always be torqued to the Seakeeper specification. All Seakeeper provided bolts are metric course thread. Hardware specifications are also listed in the Installation Manuals and Installation Details Drawings.

Refer to Seakeeper Drawing No. 90714 – Seakeeper 40 Bolt-In Installation Details. Important dimensional and load information is given in this drawing that will impact the design details of the structure that will receive the Seakeeper. It is assumed that a proper structural analysis has been performed for the hull structure to which the Seakeeper will be fastened to ensure proper strength margins for the loads the Seakeeper will create during operation.

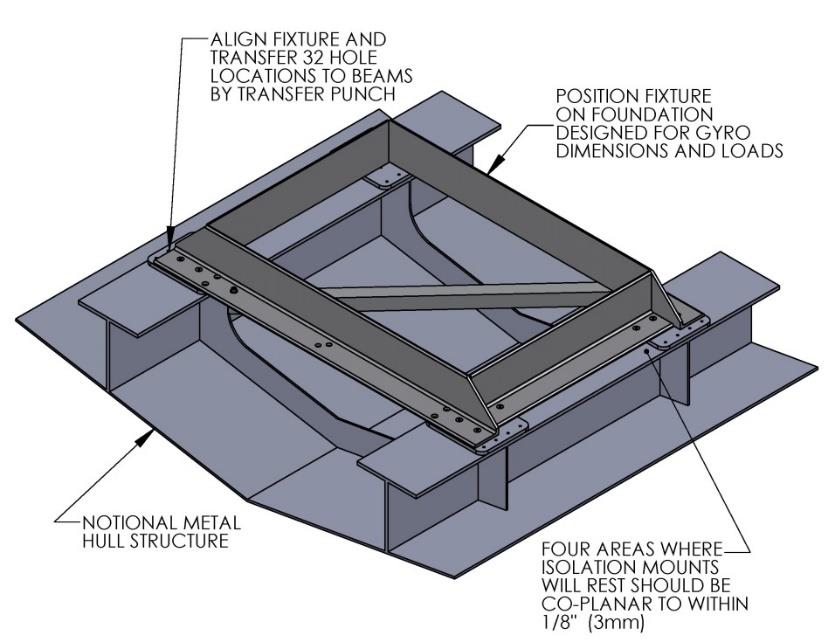

The hull structure supporting the Seakeeper should be arranged so the Seakeeper is parallel to the waterline in the forward-aft and port-starboard directions (with up to 2° allowance for trim). In addition, the four areas on top of the beams on which the isolation mounts will rest, need to be co-planar within 0.12 in. (3 mm) to minimize potential distortion of Seakeeper support frame when installed.

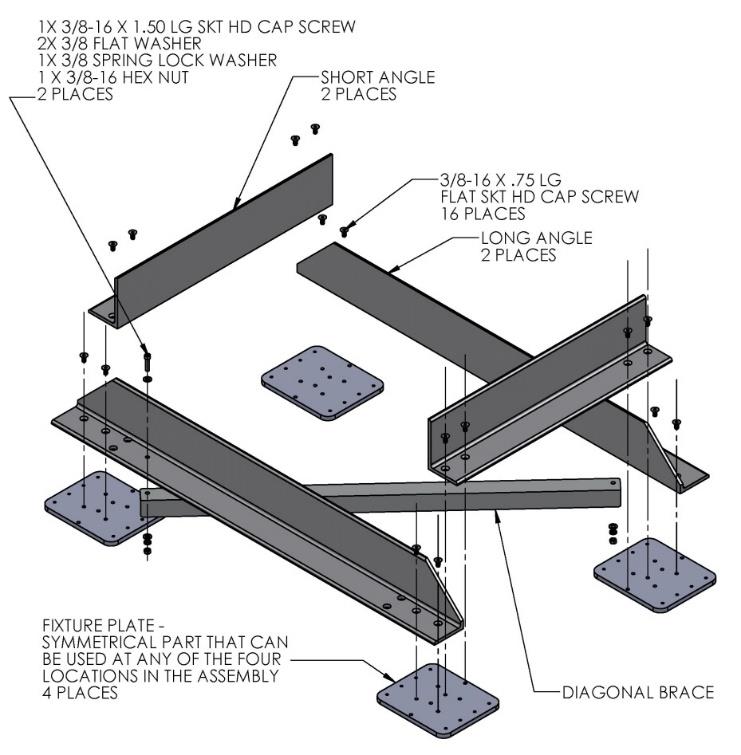

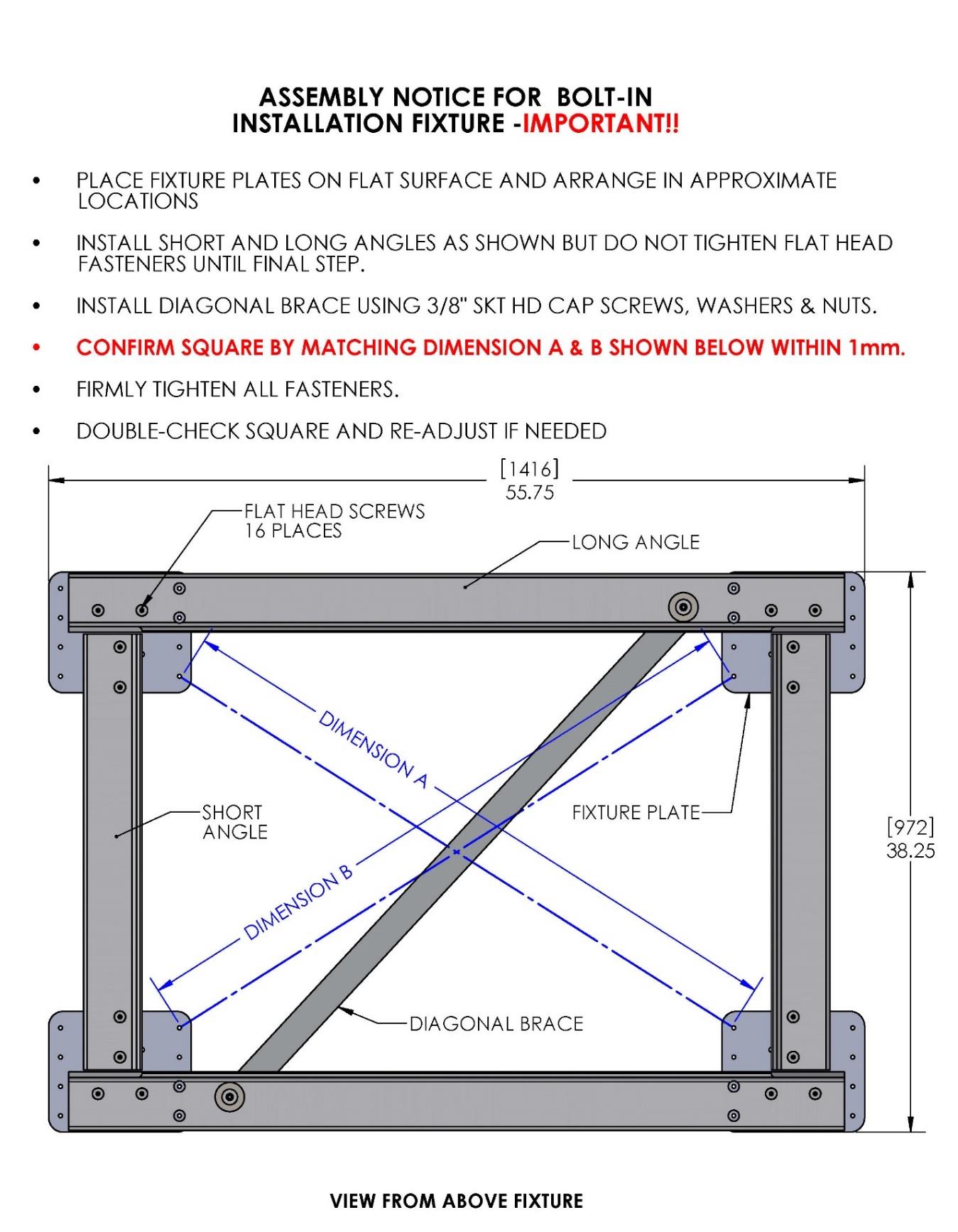

Seakeeper provides an installation fixture assembly (P/N 90089), which contains four plates that mimic the mating surfaces of the four isolation mounts located on the Seakeeper’s foundation. These plates have 8 holes located at the same centers as the holes in the isolation mounts. These smaller holes can be used to locate the holes in the ship’s structure through use of a transfer punch or drill. The fixture locates the hole patterns at the proper spacing, both in the fore-aft direction and the port-starboard direction. See Figures 4 & 5 below. Once assembled, the fixture can be used to check clearances and alignment of the hull structure.

Note: Do NOT use the installation fixture to establish Seakeeper envelope dimensions. Refer to Drawing No. 90714 – Seakeeper 40 Bolt-In Installation Details, for envelope dimensions. A 3-D model of the Seakeeper is available on the Seakeeper website (www.seakeeper.com) to aid in designing the Seakeeper foundation and the space around the Seakeeper.

CAUTION: Tight clearances from cable guide bands to hull structure. See above figure for dimensions and reference Seakeeper Drawing No. 90714 – Seakeeper 40 Bolt-In Installation Details, for complete envelope.

2.3.2 Transfer of Holes to Boat Structure

- Lower assembled fixture onto hull structure.

- The four areas where the isolation mounts will rest should be coplanar to within 0.12 in. (3 mm). See figure below. Do not use the fixture to check co-planarity as it is not stiff enough.

- Align fixture in desired location and transfer holes from fixture plate to the hull structure. A transfer punch is recommended for this step. Note that holes in fixture plate are ø.257 in. (6.5 mm).

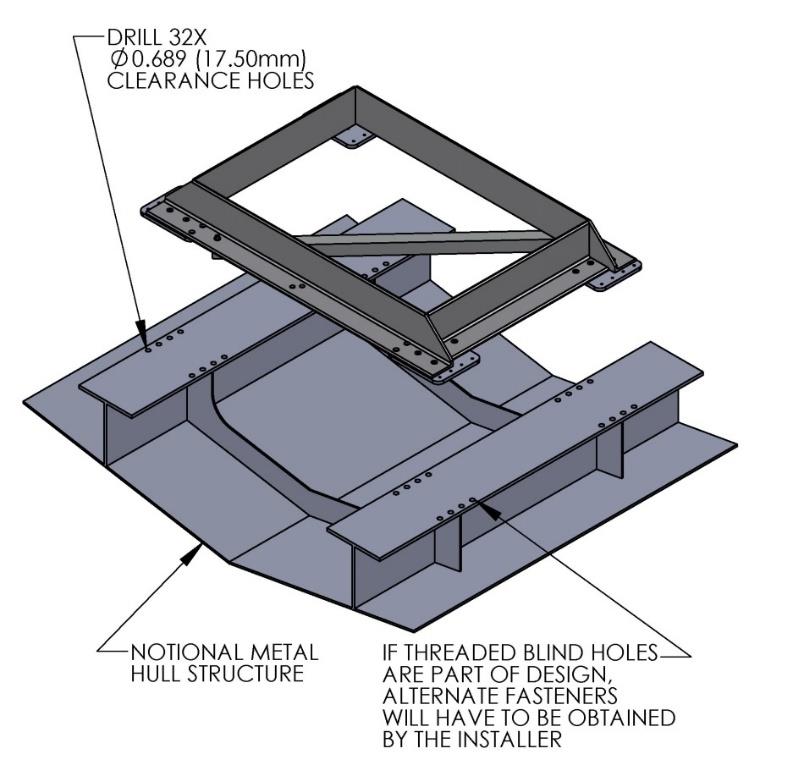

- Remove fixture and drill holes in hull structure at marked locations to mate with holes in Seakeeper isolation mounts. A ø.689 in. (17.5 mm) hole is recommended for the provided M16 fasteners.

NOTE: Certain foundation designs that employ threaded blind holes in thick plates may require the installer to obtain alternate fasteners.

2.3.3 Installation of Seakeeper

- Locate and position 4 isolation gaskets (P/N 10534) onto foundation beams (for metal to metal contacts only).

NOTE: A FILM OF SEALANT SHOULD BE APPLIED TO THE GASKET TO KEEP WATER FROM WICKING INTO THE JOINT. - Lower Seakeeper into position onto foundation beams and align over drilled holes.

- Install Mounting Bolts:

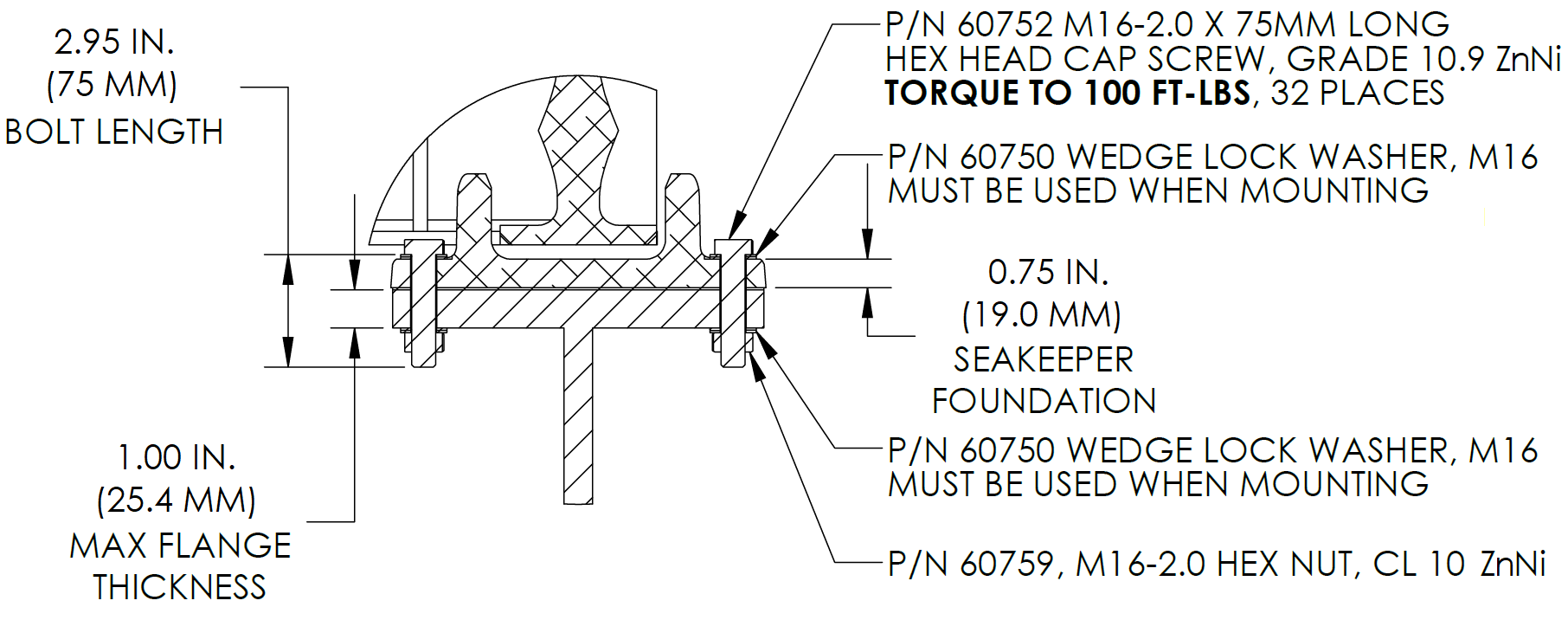

- For Through-Bolt installations (P/N 90086 – Seakeeper 40 Thru-Bolt Kit), install the Seakeeper supplied M16-2.0 fasteners to maintain a minimum of 2 threads protruding past nut. Apply a moderate coat of nickel-based anti-seize (e.g., SAF-T-EZE nickel grade anti-seize, SBT-4N or equivalent) to the threads of each bolt and include a small bead of marine grade sealant (e.g., SILI-THANE 803 or equivalent) under each bolt head and washer before installation. See Figure 6.

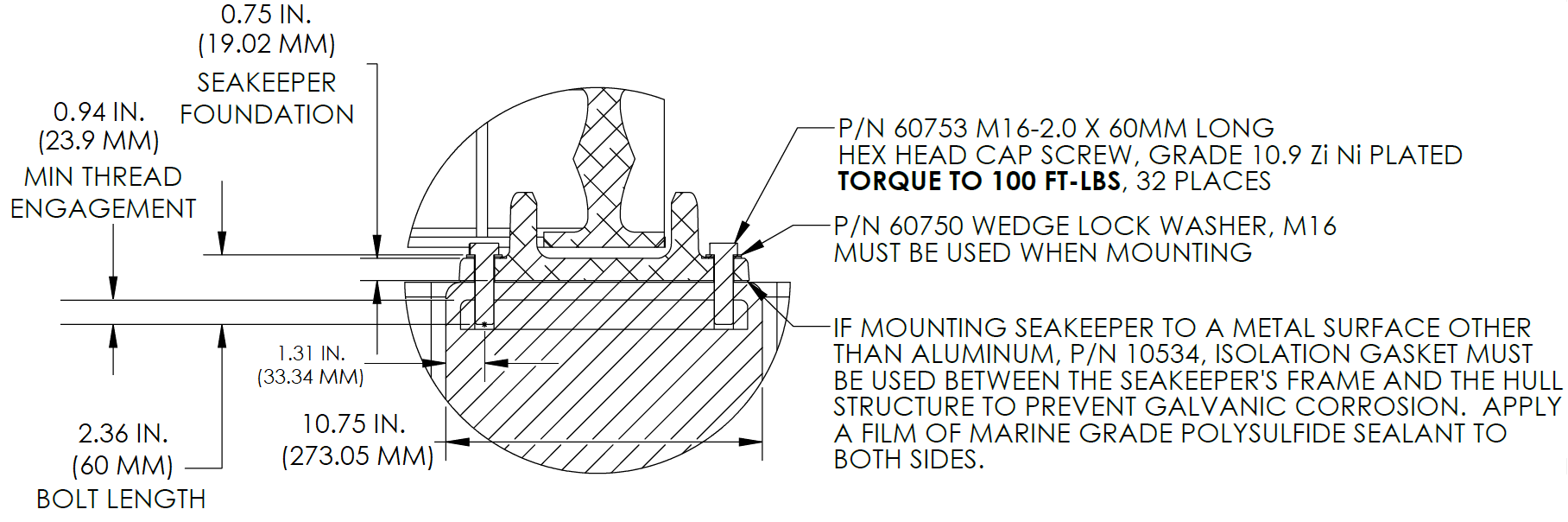

- For Blind-Hole installations (P/N 90614 – Seakeeper 40 Bolt-In Kit), install the Seakeeper supplied M16-2.0 fasteners to maintain a minimum thread engagement of 0.95 in. (24 mm). Apply a moderate coat of nickel-based anti-seize (e.g., SAF-T-EZE nickel grade anti-seize, SBT-4N or equivalent) to the threads of each bolt and include a small bead of marine grade sealant (e.g., SILI-THANE 803 or equivalent) under each bolt head and washer before installation. See Figure 7.

- Torque all fasteners to 100 ft-lbs (136 N-m).

- New bolts, matching the Seakeeper specification, must be used for each installation and reinstallation that meet the requirements listed above.

- Proceed to electrical and cooling portion of the installation.