Seakeeper 3 Installation Manual (90378-7); S/N 3-232-4223 to Current

3.2 Electrical Equipment Power Connections

Reversing polarity on the DC power input to the Seakeeper can result in damaging the electronics in the control system.

3.2.1 High Current 12 VDC Power Source Requirements:

| Source | Battery Bank, 12 VDC, Marine, Deep Cycle |

| Voltage Range | 11 – 15 VDC |

| Continuous Current | 80 A (maximum, spool up) |

| Overcurrent Protection | 100 A (Customer Supplied) |

3.2.2 High Current 12 VDC Power Connection Instructions

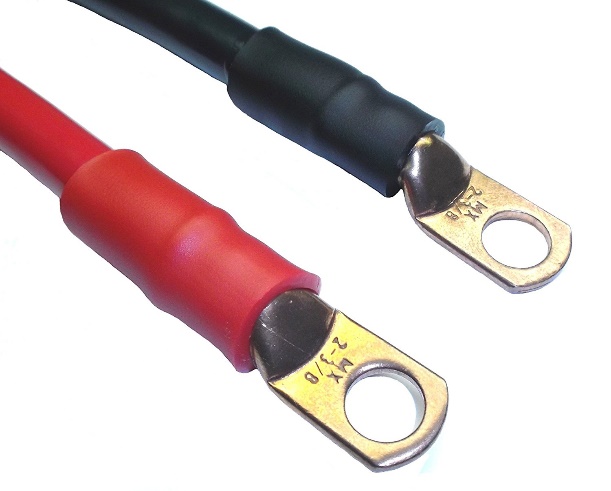

- Connect high-current power red and black cables, 2 AWG conductors, to the 12 VDC power source.

- Both cables (red and black) are supplied at length 13 ft (4 m) and approximately 0.5 m is routed within the gyro frame.

- Connect high-current power positive (B+, red) conductor through 100 A overcurrent protection device, dedicated battery isolation switch (customer supplied), and to battery positive (B+) terminal.

- Connect high-current power negative (B-, black) conductor directly to battery negative (B-) terminal or to vessel main negative bus.

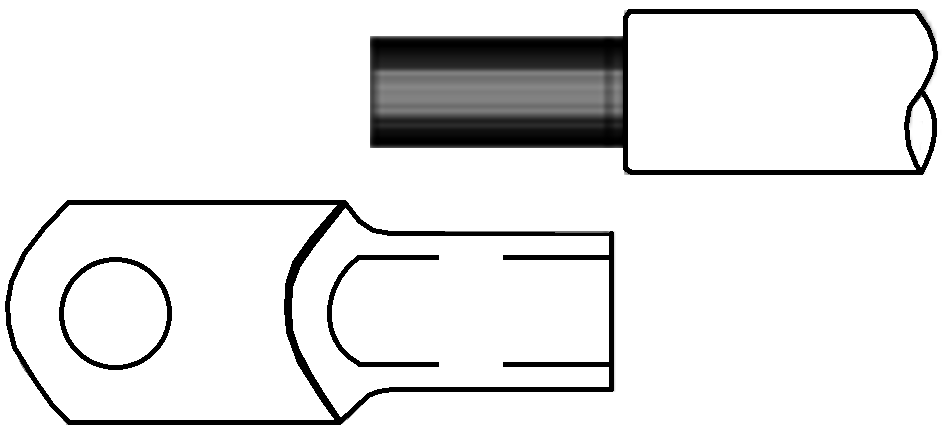

- If the 2 AWG high current 12 V power input conductors are shortened or lengthened, use heavy-duty eyelet (closed end) terminal such as Molex 19221-0235 and follow instructions outlined in the following steps.

- The bare wire strands should extend fully into the barrel of the heavy-duty eyelet and be crimped in two places if possible then sealed with double-wall heat shrink tubing. Crimp heavy-duty terminals with Quick Cable 4245 Crimp Tool, Molex19284-0034 Crimp Tool, or equivalent using manufacturer’s instructions.

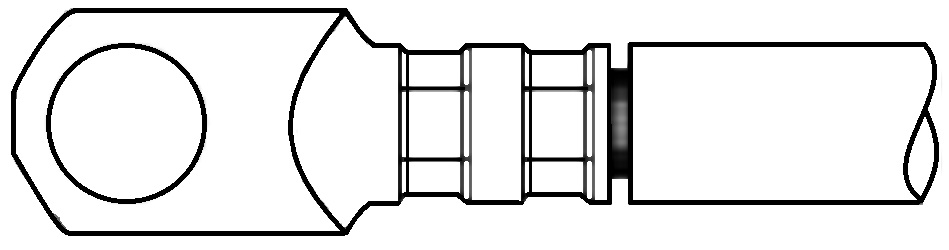

- Use heavy-duty eyelet (closed end) terminal such as Molex 19221 – Strip insulation from 2AWG conductor to the length of the terminal barrel approximately as shown.

- Insert stripped end of 2 AWG conductor fully into barrel of heavy-duty eyelet (closed end) terminal, approximately as shown.

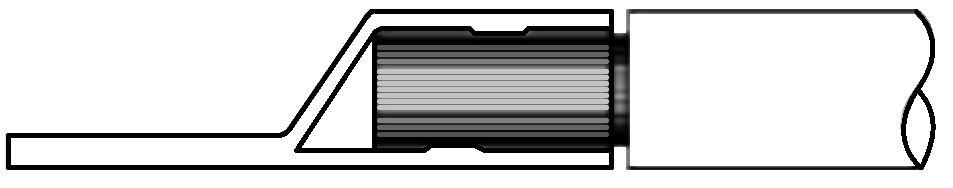

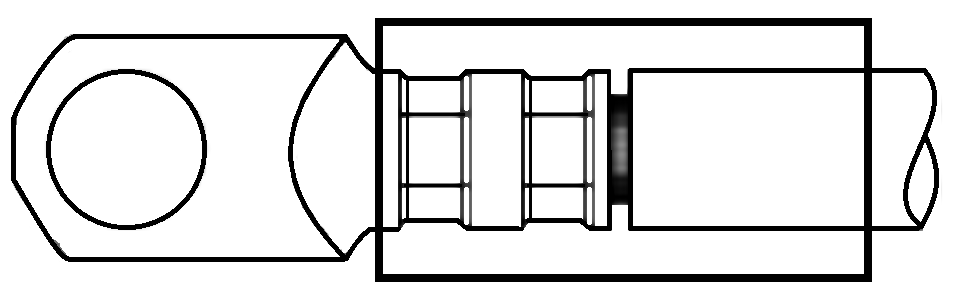

4. Crimp with quick cable 4245 cub crimp tool or equivalent, double

crimp, as shown.

- The resultant crimp(s) should fully enclose and confine the conductor strands from all sides and withstand an aggressive manual pull test.

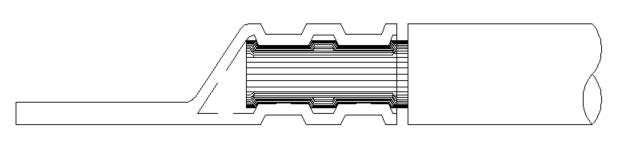

- Install approximately 1.5 in. (38 mm) of double wall (adhesive lined) heat shrink tubing over both the terminal barrel and the conductor insulation. Heat shrink in place until tubing conforms to barrel and conductor shape and adhesive seals the junction (See Figure 13).

3.2.3 Low Current 12 VDC Power Source Requirements

| Source: | Battery Bank, 12 VDC, Marine Deep Cycle (Seakeeper recommends AGM batteries) |

| Voltage Range: | 11 – 15 VDC |

| Continuous Current: | 9 A |

| Overcurrent Protection: | 15 A (Customer Supplied) |

3.2.4 Low Current 12 VDC Power Connection Instructions

Reversing polarity on the DC power input to the Seakeeper can result in damaging the electronics in the control system.

- Install Seakeeper-provided Low Current DC Power Input Cable, (P/N 20248), to battery bank, per Drawing Number 90377.

- Connect control power positive conductor (B+, red) through dedicated over-current protection device (customer supplied) and a dedicated Seakeeper isolation switch (customer supplied). A 2AWG, B+ conductor (red), is capable of carrying the current for both the High Current, Low Current, and Seawater Pump from the 12VDC power supply to the dedicated battery isolation switch.

- Connect control power negative conductor (B-, black) directly to battery minus terminal or negative DC bus bar.

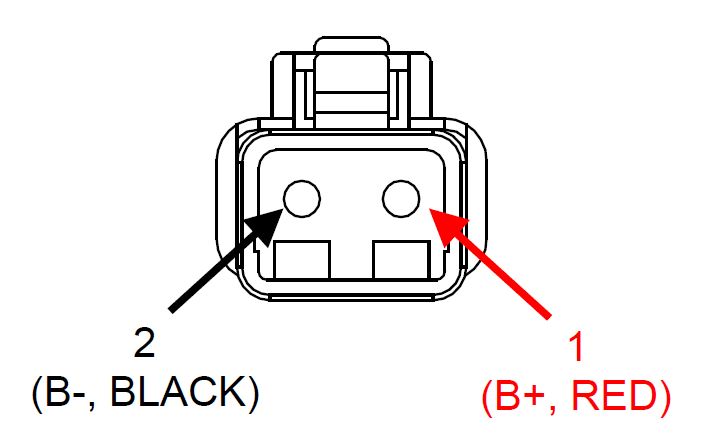

- Before connecting low-current control power cable to Seakeeper, check for proper voltage and polarity with a DC multimeter using Figure 14 below.

- Connect low-current control power cable to Low Current 12 VDC power input connector on the Seakeeper, Deutsch DTP04-2P connector.

3.2.5 DC Seawater Pump Power Source Requirements

| Source: | 12 VDC from the Seakeeper |

| Voltage Range: | 11 – 15 VDC |

| Current Rating: | On Demand, typically ~ 10 A |

| Overcurrent Protection | Per pump specification, max 15 A |

3.2.6 DC Seawater Pump Power Connection Instructions

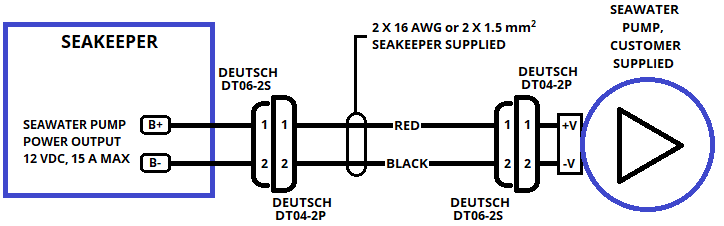

DC Seawater Pump Power Input Connection:

- Install Seawater Pump 12VDC Input Cable (P/N: 30327) to Seakeeper 3 “SW Pump DC In” (as shown in Drawing No. 90377) with overcurrent protection corresponding to seawater pump selected.

- Connect the 16 AWG positive conductor (red) through dedicated overcurrent protection device (customer-supplied), maximum of 15 A, to dedicated battery isolation switch.

- Connect the 16 AWG negative conductor (black) directly to battery negative terminal or DC main negative bus bar.

- Before connecting Seawater Pump 12VDC IN cable to Seakeeper, check for proper voltage and polarity with a DC multimeter using Figure 15 below.

- Connect Seawater Pump 12VDC Cable to Seawater Pump 12 VDC In connector on the Seakeeper, Deutsch DT04-2P connector.

DC Seawater Pump Power Output Connection:

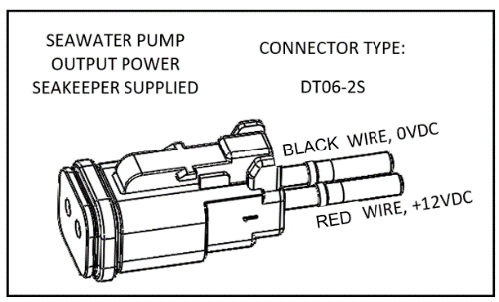

- Connect Seawater Pump 12VDC Output Cable to the Seakeeper 3 “SW Pump 12VDC Out” for DC power output to the seawater pump.

- The Seawater Pump 12VDC Output Cable is a 2 x 16AWG cable, 16 ft (5 m) length, with a size 16 female Deutsch plug.

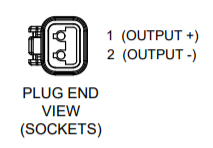

- Pumps rated at 12 VDC, 15 A maximum, customer-supplied, must be configured with a Deutsch DT series, 2-pin receptacle to mate with the connector shown in Figure 16.

- The Seawater Pump 12VDC Output cable must be routed and installed in the vessel from the Seakeeper 3 “SW Pump12VDC Out” Deutsch connector (pins end) to the DC seawater pump cable Deutsch connector (socket end).

- Connect the Seawater Pump Output cable plug end (socket end) to the customer-supplied receptacle end (pin end). The recommended wiring is shown in Figure 17.