Seakeeper 3 Installation Manual (90378-7); S/N 3-232-4223 to Current

2.3.3 Installation of Seakeeper

- Lower Seakeeper into position onto the hull foundation beams and align over drilled holes. Apply a small bead of marine sealant (e.g., SILI-THANE 803 or equivalent)between mating surfaces of Seakeeper frame and hull structure to prevent moisture wicking into bolt holes.

- For dissimilar metal foundations locate and position 4 isolation gaskets onto foundation beams and apply a small bead of marine sealant (e.g., SILI-THANE 803 or equivalent) between both mating surfaces of each isolation gasket where it contacts the beam and the Seakeeper (See Figure 9).

- Install mounting bolts:

- For Blind Hole Installations, install the Seakeeper supplied Grade 10.9, M16-2.0 x110 mm fasteners or alternative Grade 10.9, M16-2.0 bolts to maintain a minimum thread engagement of .94 in (24 mm). If Seakeeper supplied bolts do not achieve the minimum thread engagement because of the lamination thickness or structure, longer bolts of the same specification (M16-2.0, Grade10.9) should be sourced. If tapping directly into a metal frame shorter bolts maybe required. Apply a moderate coat of marine anti-seize (e.g., SAF-T-EZE nickel grade anti-seize, SBT-4N or equivalent) to the threads of each bolt and include a small bead of marine grade sealant (e.g., SILI-THANE 803 or equivalent) under each bolt head and washer before installation. See Figure 10 below.

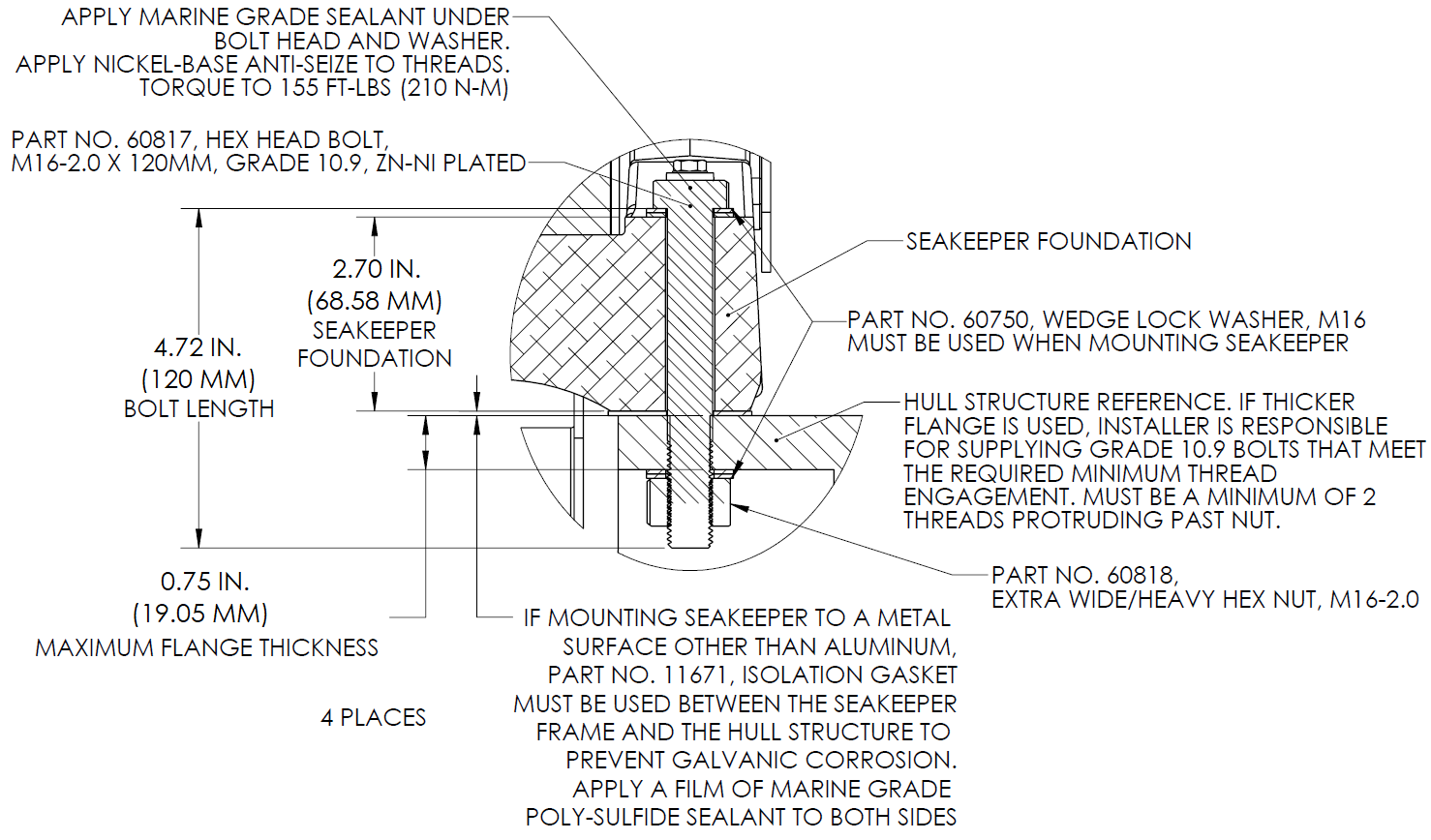

- For Through-Bolt installation install the Seakeeper optional Thru-Bolt Kit (P/N 90641) Grade 10.9, M16-2.0 x 120 mm fasteners with a minimum of 2 threads passing through the nut If Seakeeper supplied bolts do not pass entirely through the Extra Wide / Heavy Hex Nut because of the frame thickness, longer bolts of the same specification (M16-2.0, Grade 10.9) should be sourced. Apply a moderate coat of marine anti-seize (e.g., SAF-T-EZE nickel grade anti-seize, SBT-4N or equivalent) to the threads of each bolt and include a small bead of marine grade sealant (e.g., SILI-THANE 803 or equivalent) under each bolt head and washer before installation. See Figure 11 below.

- Torque all fasteners to 155 ft-lbs (210 Nm).

- New bolts matching the Seakeeper specification must be used for each installation.

- Proceed to electrical and cooling portion of the installation.