Seakeeper 3 Installation Manual (90378-6); S/N 3-223-3836 to 3-231-4222

2.3 Bolt-In Installation

2.3.1 Preparation of Boat Structure

The Seakeeper Drawing No. 90591, Seakeeper 3 Generic Installation Guide shows various structural arrangements to support the installation of the Seakeeper. The Generic Installation Guide offers above and below deck installation arrangements with fiber-reinforced plastic (FRP) and aluminum structures, which should provide solutions for most vessels. The Seakeeper 3 is affixed to the hull structure via four bolts in the

Seakeeper 3 frame. Depending on the structure to which the Seakeeper is fastened, blind threaded holes or through-bolting can be utilized.

Refer to Seakeeper Drawing No. 90374, Seakeeper 3 Bolt in Installation Guide. Important dimensional and load information is given in this drawing that will impact the design details of the structure that will receive the Seakeeper. It is assumed that a proper structural analysis has been performed for the hull structure to which the Seakeeper will be fastened to ensure proper strength margins for the loads the Seakeeper will create during operation.

The hull structure supporting the Seakeeper should be installed so the Seakeeper is parallel to the waterline in the transverse direction and within 1 degree longitudinally.

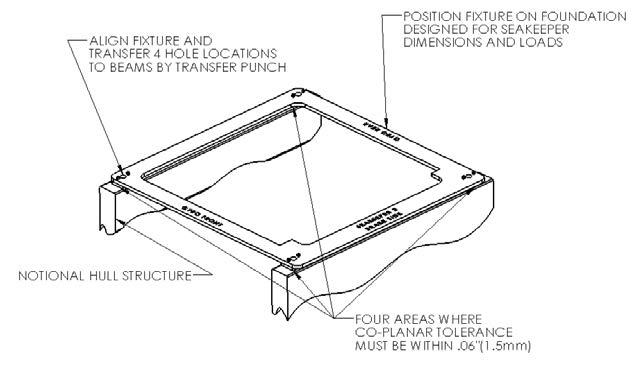

In addition, the four areas on top of the structure on which the Seakeeper 3 frame and isolation gaskets will rest, need to be co-planar within .06 in. (1.5 mm) to minimize potential distortion of Seakeeper support frame when installed. The isolation gaskets are only used when the Seakeeper 3 is mounted to a dissimilar metal structure.

Seakeeper offers an optional installation template kit, P/N 90362, which contains four plates that mimic the mating surfaces of the four feet located on the Seakeeper ’s foundation. These plates have 4 holes located at the same centers as the mounting holes on the Seakeeper 3.The fixture locates the hole patterns at the proper spacing both in the forward-aft direction and the port-starboard direction. See Figure 5 below. Once assembled, the fixture can be used to check clearances and alignment of the hull structure.

Note: Do NOT use the installation fixture to establish the Seakeeper envelope dimensions. Refer to Drawing No. 90374 – Seakeeper 3 Bolt-In Installation Details, for envelope dimensions. A 3-D model of the Seakeeper is available on the Seakeeper Dealer Access website (www.seakeeper.com) to aid in designing the Seakeeper foundation and the space around the Seakeeper

NOTE: MAKE SURE NO OBSTRUCTIONS FROM THE HULL STRUCTURE CAN BE SEEN WITHINTHE INSIDE OF THE INSTALLATION TEMPLATE KIT (INSIDE THE MARKED RED LINES) AS SEEN IN FIGURE 4. REFERENCE SEAKEEPER DRAWING NO. 90374 – SEAKEEPER 3 BOLT-ININSTALLATION DETAILS

.

CAUTION: Tight clearances from cable guide bands to hull structure.

See above figure for dimensions and reference Seakeeper Drawing No. 90374,

Seakeeper 3 Bolt-In Installation Details, for complete Seakeeper 3 envelope.

2.3.2 Transfer of Holes to Boat Structure

- Lower assembled fixture onto hull structure.

- The four areas where the feet of the Seakeeper will rest should be coplanar to within .06 in. (1.5 mm). See Figure 5.

- Align fixture (P/N 90362) in desired location and transfer holes from fixture plate to the hull structure.

Note: Holes in fixture plate are ø0.64 in. (16.26 mm).

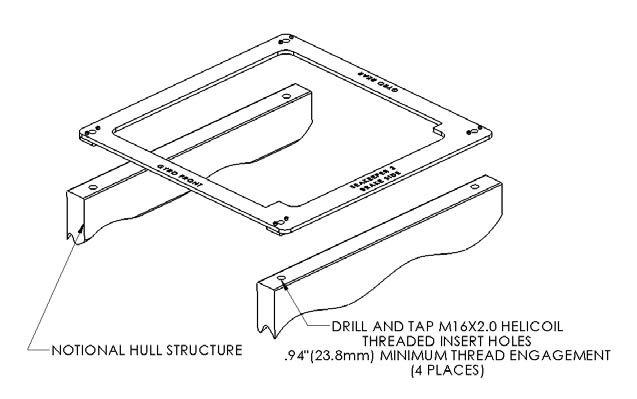

2.3.2.1 Blind Hole Installation

- Remove Template Fixture and drill four (4) 0.65 in. (16.5 mm) holes perpendicular to the vessel structure to a minimum depth of 0.94 in. (24 mm). Take special care to drill perpendicular to mounting surface. A drill guide is recommended. Remove any impeding obstructions.

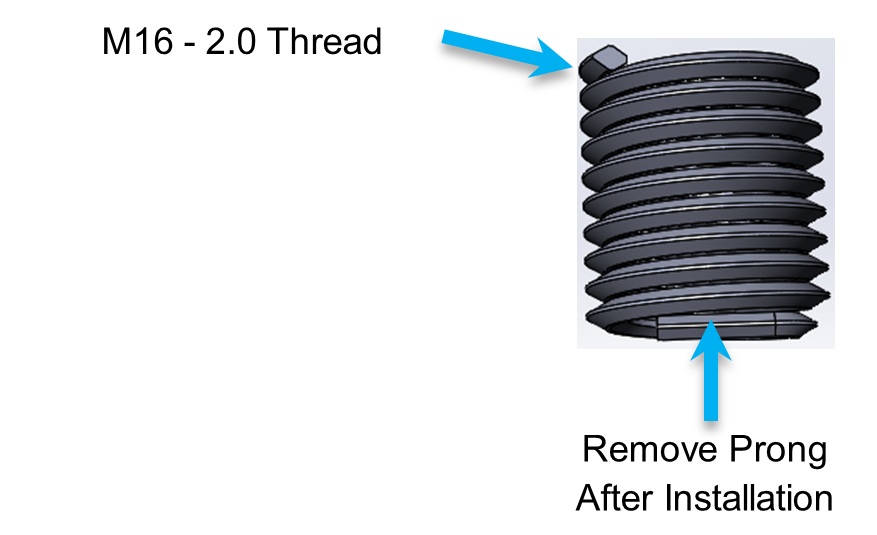

- Tap drilled holes for helical thread inserts per documentation accompanying helical threaded inserts. (Tap will be included in thread insert kit.)

- Install four (4) M16-2.0 X 24 mm threaded inserts into holes in hull structure at drilled and tapped locations using threaded insert manufacturer provided installation tool.

- Remove threaded insert prong / tang after threaded inserts are installed.

2.3.2.2 Through-Hole Installation

- Remove Template Fixture and drill four (4) 0.67 in. (17 mm) ø holes perpendicular to the vessel structure.

NOTE: Take special care to drill perpendicular to mounting surface. A drill guide is recommended.

2.3.3 Installation of Seakeeper

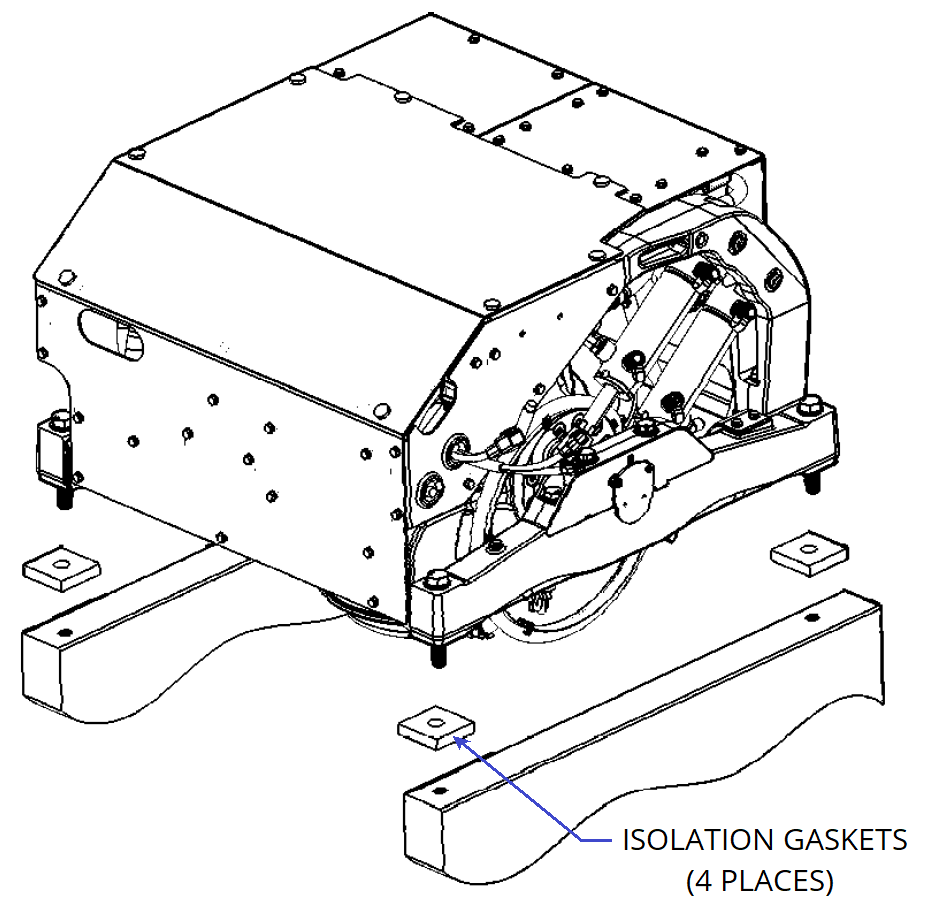

- Lower Seakeeper into position onto the hull foundation beams and align over drilled holes. Apply a small bead of marine sealant (e.g., SILI-THANE 803 or equivalent)between mating surfaces of Seakeeper frame and hull structure to prevent moisture wicking into bolt holes.

- For dissimilar metal foundations locate and position 4 isolation gaskets onto foundation beams and apply a small bead of marine sealant (e.g., SILI-THANE 803or equivalent) between both mating surfaces of each isolation gasket where it contacts the beam and the Seakeeper (See Figure 6).

- Install mounting bolts:

- For Blind Hole Installations, install the Seakeeper supplied Grade 10.9, M16-2.0 x110 mm fasteners or alternative Grade 10.9, M16-2.0 bolts to maintain a minimum thread engagement of .94 in (24 mm). If Seakeeper supplied bolts do not achieve the minimum thread engagement because of the lamination thickness or structure, longer bolts of the same specification (M16-2.0, Grade10.9) should be sourced. If tapping directly into a metal frame shorter bolts maybe required. Apply a moderate coat of marine anti-seize (e.g., SAF-T-EZE nickel grade anti-seize, SBT-4N or equivalent) to the threads of each bolt and include a small bead of marine grade sealant (e.g., SILI-THANE 803 or equivalent) under each bolt head and washer before installation. See Figure 7 below.

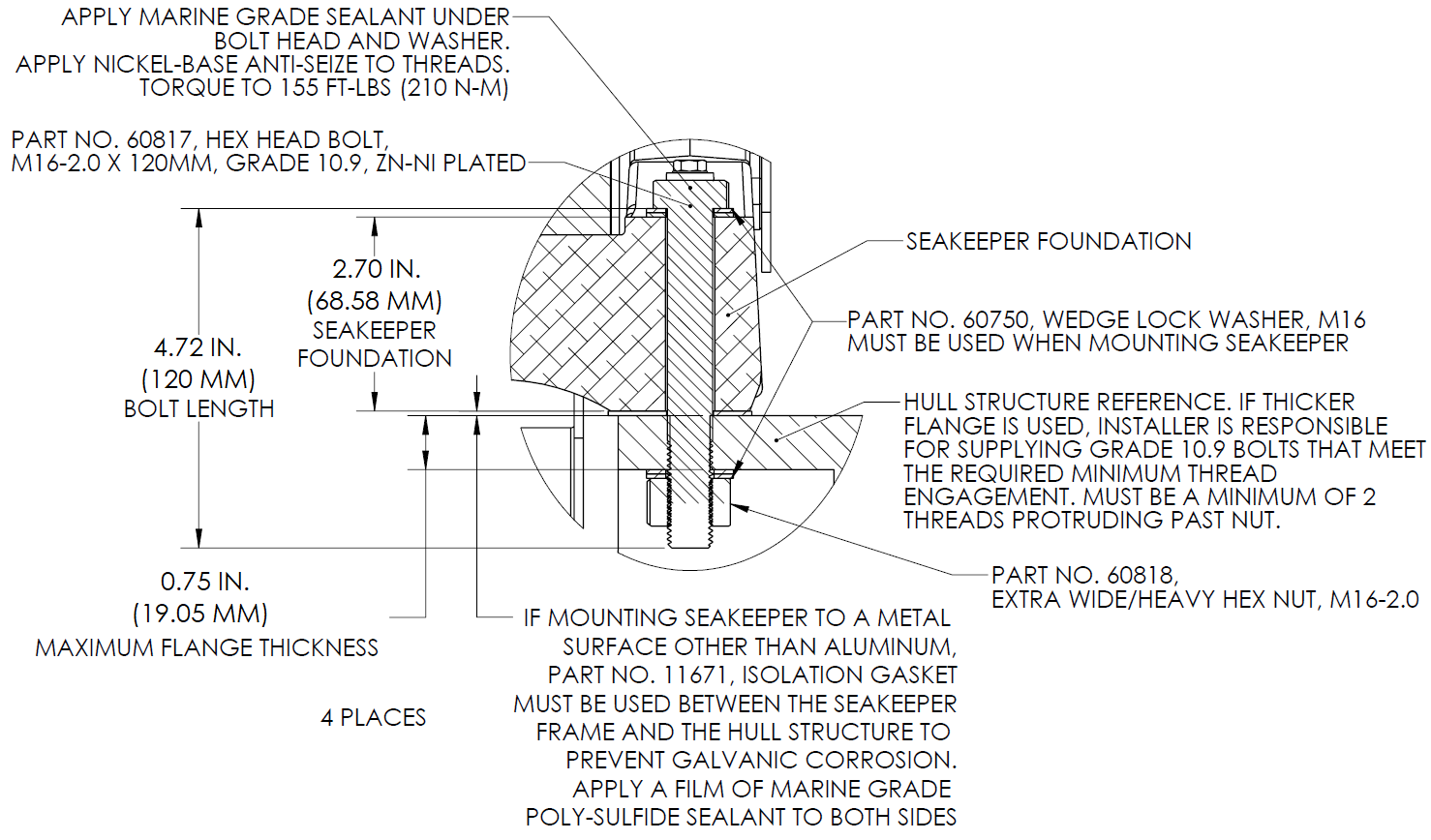

- For Through-Bolt installation install the Seakeeper optional Thru-Bolt Kit (P/N90641) Grade 10.9, M16-2.0 x 120 mm fasteners with a minimum of 2 threads passing through the nut If Seakeeper supplied bolts do not pass entirely through the Extra Wide / Heavy Hex Nut because of the frame thickness, longer bolts of the same specification (M16-2.0, Grade 10.9) should be sourced. Apply a moderate coat of marine anti-seize (e.g., SAF-T-EZE nickel grade anti-seize, SBT-4Nor equivalent) to the threads of each bolt and include a small bead of marine grade sealant (e.g., SILI-THANE 803 or equivalent) under each bolt head and washer before installation. See Figure 8 below.

- Torque all fasteners to 155 ft-lbs (210 Nm).

- New bolts matching the Seakeeper specification must be used for each installation.

- Proceed to electrical and cooling portion of the installation.

3.0 Electrical Installation

3.1 Electrical Installation Introduction

This section for electrical installation explains how to mount the electrical equipment and how to connect the electrical cables.

Reference Documents:

- 90377 – Seakeeper 3 Cable Block Diagram

- 90467 – Second Helm Station 5″ Display

- 90558 – ConnectBox Helm Mounting Kit

- TB-90191 – Seawater Cooling Pump Recommendations

- TB-90575 – DC Installation Kits

- TB-90621 – Seakeeper Battery Sizing Recommendations

- Seakeeper Compatibility Technical Bulletins

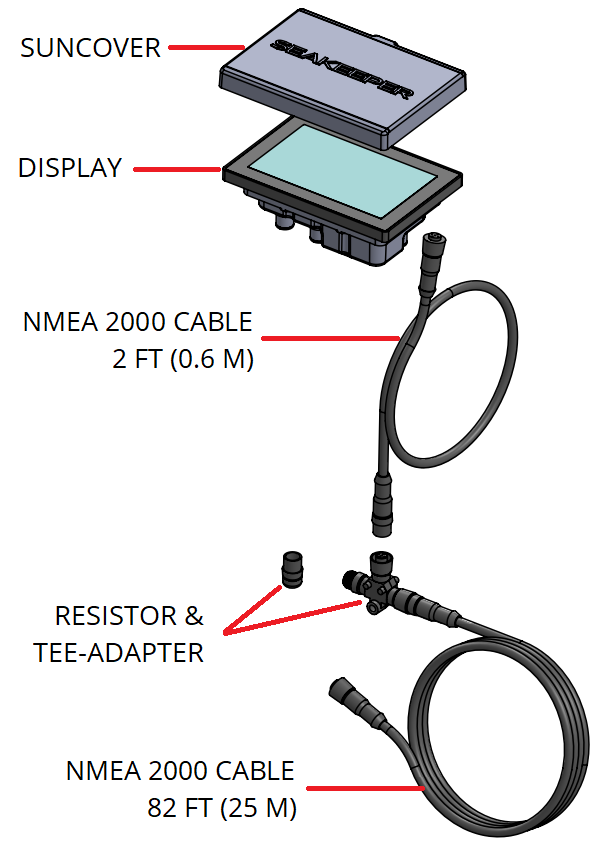

The following images (Figure 1) show the electrical equipment included with the Seakeeper 3 Hardware Scope of Supply (Drawing No. 90388):

16.4 ft (5 m) (20334)

19.7 ft (6 m)(30332)

16.4 ft (5 m) (30327)

Figure 1 – Electrical Equipment for Seakeeper 3

3.2 Electrical Equipment Power Connections

3.2.1 High Current 12 V Power Input

This Section outlines the requirements and process for connecting the Seakeeper 3 High Current 12 VDC power input.

3.2.1.1 High Current 12 VDC Power Source Requirements

| Source: | Battery Bank, 12 VDC, Marine Deep Cycle (Seakeeper recommends AGM batteries) |

| Voltage Range: | 11 – 15 VDC |

| Continuous Current: | 85 A (Max) |

| Overcurrent Protection: | 100 A (Customer Supplied) |

3.2.1.2 High Current 12 VDC Power Connection Instructions

- The 2 AWG conductors to connect the high current DC input power are supplied at13.12 ft (4 m). Approximately 3.28 ft (1 m) is routed within the gyro frame.

- The 2 AWG conductor length may be increased to a maximum of 29.53 ft (9 m), but changing from 2 AWG to larger wire size does not allow longer length. The length limit is required to limit the inductance from the high current conductors.

- Use the shortest length and most direct route to the battery bank as possible.

- Bind plus (B+, red) & minus (B-, black) conductors together throughout entire length and do not coil excess wire.

- Connect plus conductor (B+, red) through dedicated 100A over-current protection device (customer supplied) and a dedicated battery isolation switch (customer supplied) then directly to battery plus terminal or positive DC bus bar.

- Connect minus conductor (B-, black) directly to battery minus terminal.

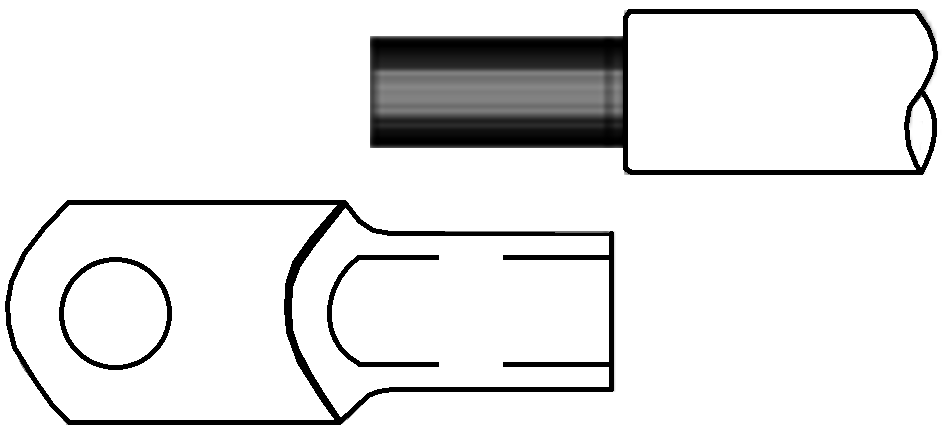

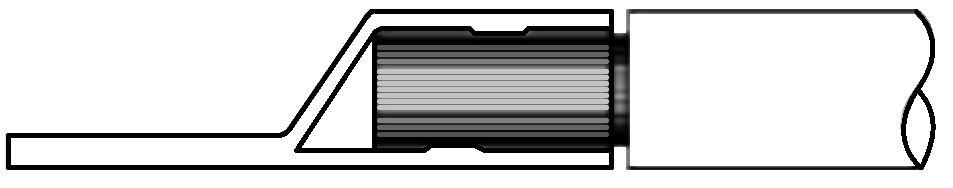

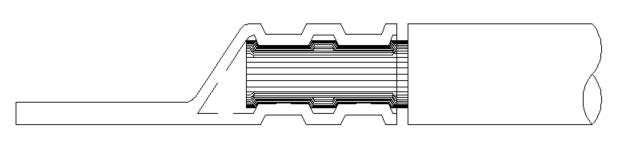

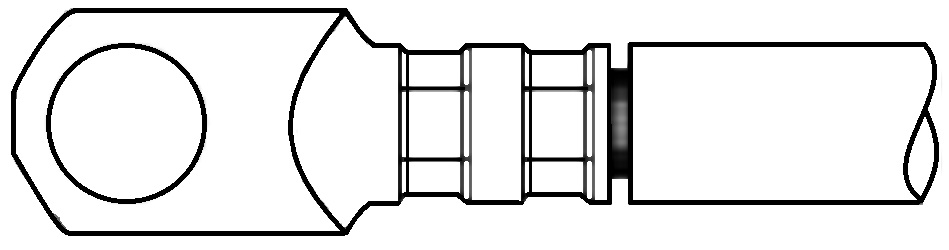

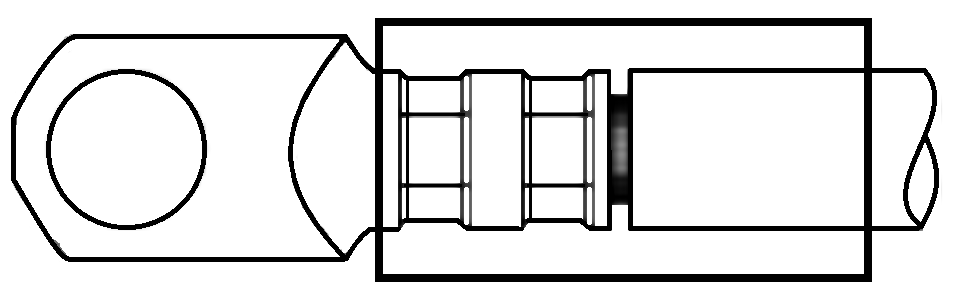

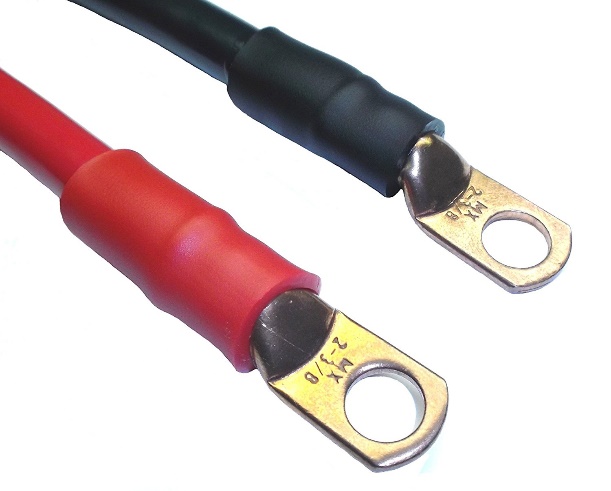

- If the 2 AWG high current 12 V power input conductors are shortened or lengthened, use heavy-duty eyelet (closed end) terminal such as Molex 19221-0235 and follow instructions outlined in the following steps.

- The bare wire strands should extend fully into the barrel of the heavy-duty eyelet and be crimped in two places if possible then sealed with double-wall heat shrink tubing. Crimp heavy-duty terminals with Quick Cable 4245 Crimp Tool, Molex19284-0034 Crimp Tool, or equivalent using manufacturer’s instructions.

- Use heavy-duty eyelet (closed end) terminal such as Molex 19221 – Strip insulation from 2AWG conductor to the length of the terminal barrel approximately as shown.

- Insert stripped end of 2 AWG conductor fully into barrel of heavy-duty eyelet (closed end) terminal, approximately as shown.

- Crimp with quick cable 4245 cub crimp tool or equivalent, double crimp, as shown.

- The resultant crimp(s) should fully enclose and confine the conductor strands from all sides and withstand an aggressive manual pull test.

- Install approximately 1.5 in. (38 mm) of double wall (adhesive lined) heat shrink tubing over both the terminal barrel and the conductor insulation. Heat shrink in place until tubing conforms to barrel and conductor shape and adhesive seals the junction (See Figure 2).

3.2.2 Low Current 12 V Power Input

3.2.2.1 Low Current 12 VDC Power Source Requirements

| Source: | Battery Bank, 12 VDC, Marine Deep Cycle (Seakeeper recommends AGM batteries) |

| Voltage Range: | 11 – 15 VDC |

| Continuous Current: | 9 A |

| Overcurrent Protection: | 15 A (Customer Supplied) |

3.2.2.2 Low Current 12 VDC Power Connection Instructions

Reversing polarity on the DC power input to the

Seakeeper can result in damaging the electronics in the control system.

- Install Seakeeper-provided Low Current DC Power Input Cable, (P/N 20248), as Cable 7to battery bank, per Drawing Number 90377.

- Connect plus conductor (B+, red) through dedicated over-current protection device(customer supplied) and a dedicated Seakeeper isolation switch (customer supplied).The High Current, 2AWG, B+ conductor (red), is capable of carrying the current for both the High Current, Low Current, and Seawater Pump from the 12VDC power supply to the dedicated battery isolation switch.

- Connect minus conductor (B-, black) directly to battery minus terminal or negative DCbus bar.

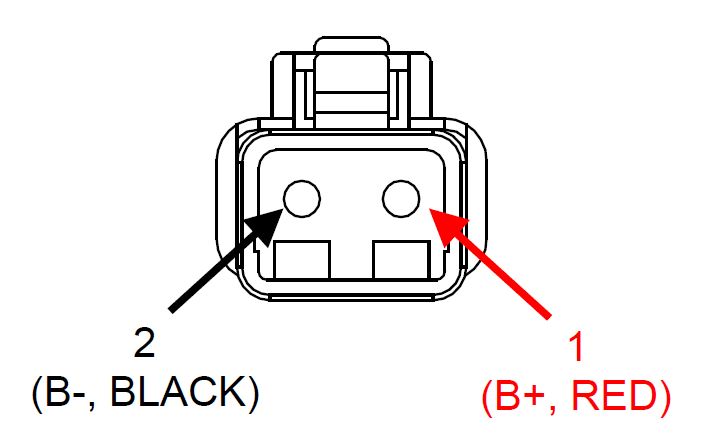

- Before connecting Cable 7 to Seakeeper, check for proper voltage and polarity with a DC multimeter using Figure 3 below.

- Connect Cable 7 to Low Current 12 VDC power input connector on the Seakeeper, DEUTSCH DTP04-2P connector.

3.2.3 Seawater Pump Connection Instructions

3.2.3.1 DC Seawater Pump 12 VDC Power Source Requirements:

| Source: | 12 VDC from the Seakeeper |

| Voltage Range: | 11 – 15 VDC |

| Current Rating: | On Demand, typically ~ 10 A |

| Overcurrent Protection | Per pump specification, max 15 A |

3.2.3.2 Seawater Pump 12 VDC Power Input Connection Instructions

- Install Cable 8 (P/N: 30327) to Seakeeper 3 “SW Pump DC In” (as shown in Drawing No. 90377) with overcurrent protection corresponding to seawater pump selected.

- Connect the 16AWG plus conductor (red) through dedicated overcurrent protection device (customer-supplied), maximum of 15A, to dedicated battery isolation switch.

- Cable 1, 2 AWG B+ conductor (red), is capable of carrying the current for both the High Current, Low Current, and Seawater Pump from the 12VDC power supply to the battery isolation switch.

- Connect the 16 AWG minus conductor (black) directly to battery minus terminal or DC main negative bus bar.

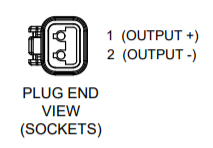

- Before connecting Cable 8 to Seakeeper, check for proper voltage and polarity with a DC multimeter using Figure 4 below.

- Connect Cable 8 to Seawater Pump 12 VDC In connector on the Seakeeper, DEUTSCHDT04-2P connector.

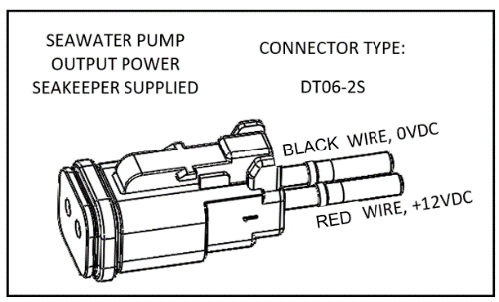

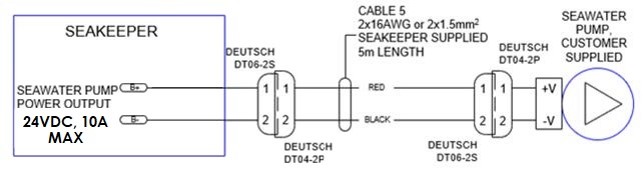

3.2.3.3 Seawater Pump 12 VDC Power Output Connection Instructions

- Connect Cable 5 to the Seakeeper 3 “SW Pump 12VDC Out” for DC power output to the seawater pump.

- Cable 5 is a 2 x 16AWG cable, 16 ft (5m) length, with a size 16 female Deutsch plug.

- Pumps rated at 12 VDC, 15 A maximum, customer-supplied, must be configured with a Deutsch DT series, 2-pin receptacle to mate with the connector shown in Figure 5.

- Cable 5 must be routed and installed in the vessel from the Seakeeper 3 “SW Pump12VDC Out” Deutsch connector (pins end) to the DC seawater pump cable Deutsch connector (socket end).

- Connect Cable 5 plug end (socket end) to the customer-supplied receptacle end (pin end). The recommended wiring is shown in Figure 6.

3.3 Electrical Equipment Ground Connections

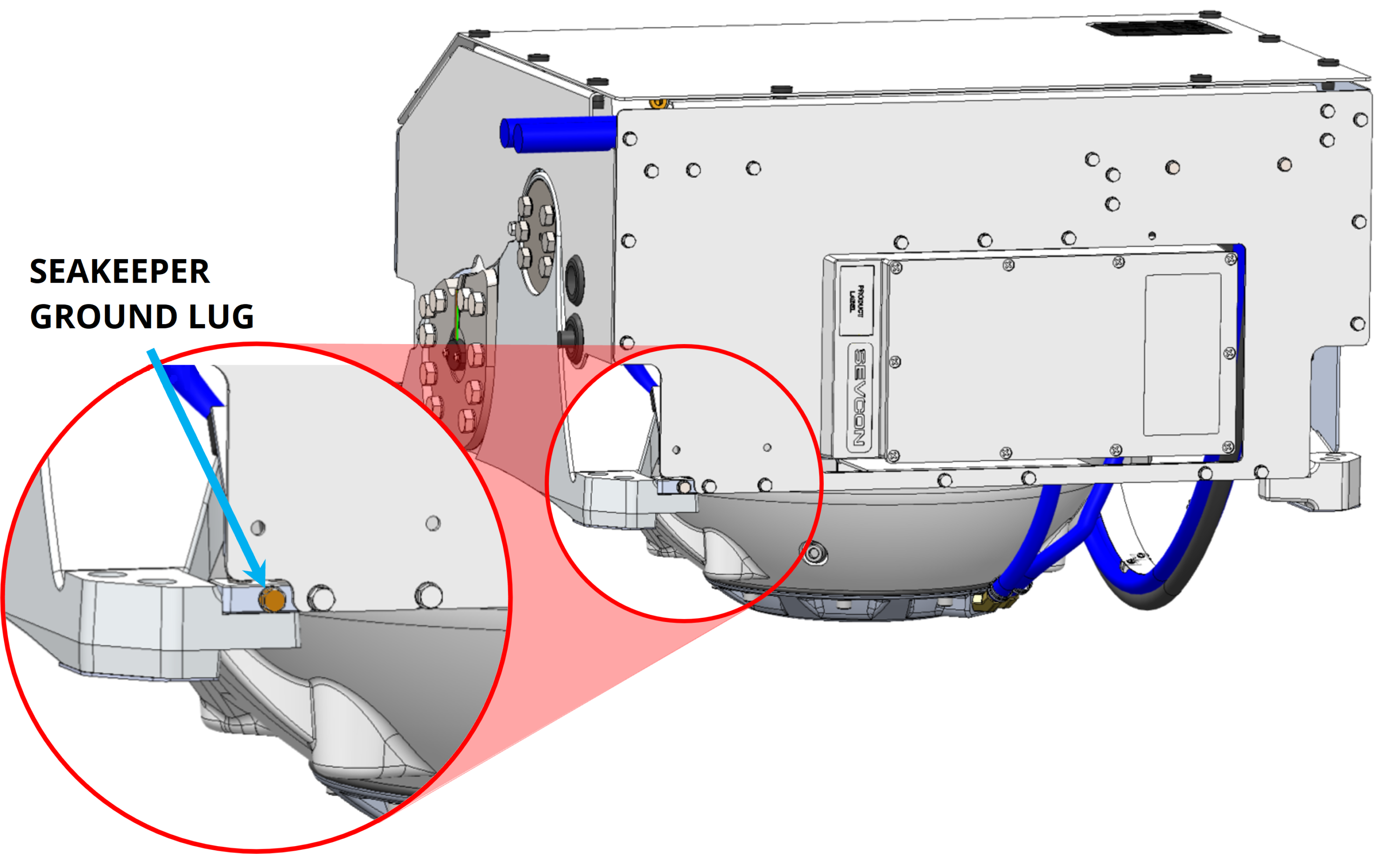

3.3.1 Seakeeper to Boat Ground Connection Instructions

- Connect the Seakeeper foundation ground stud, shown in Figure 7, to vessel ground.

- Install Cable 6 (4 AWG or 25 mm2, Customer Supplied) from the M6 brass ground stud to vessel grounding bus to comply with:

- EM/IEC 60204-1 Clauses 6.3.3 and 8.2.3.

- ABYC E-11 July 2018 Clauses 11.5.2 and 11.16.1.

- Install Cable 6 (4 AWG or 25 mm2, Customer Supplied) from the M6 brass ground stud to vessel grounding bus to comply with:

NOTE: USE ONLY THIS LOCATION FOR GROUNDING THE SEAKEEPER TO THE BOAT GROUND.

b. A proper ground connection is critically important for corrosion

protection and helps to ensure the ignition protection of the unit

by ensuring it does not carry any stray current.

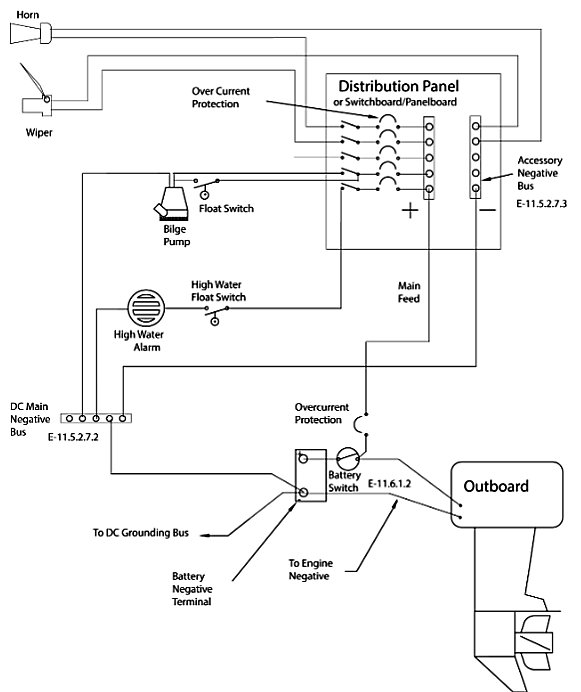

c. NOTE: the ground is not referring specifically to a bonding system

but for outboard boats generally refers to the outboard engine

negative terminal, or its bus, to the DC grounding bus. This connection

shall be used only as a means of maintaining the negative side of the

circuit at ground potential and is not to carry current under normal

operating conditions. See Figure 8.

3.4 Seakeeper Display Connection

3.4.1 Seakeeper 3 Display Options

A Seakeeper display is required with the installation of a Seakeeper 3 to support the full functionality of the unit through the Seakeeper App in addition to the ConnectBox. The Seakeeper App provides an interface for controlling the Seakeeper 3 or viewing the Settings, Service, Info, and Alarm pages. The Seakeeper ConnectBox can be helm-mounted to provide an additional interface for the control of the Seakeeper 3 but does not replace the need for a Seakeeper compatible display.

The Seakeeper 3 has several options for establishing a Seakeeper display interface to support the Seakeeper App:

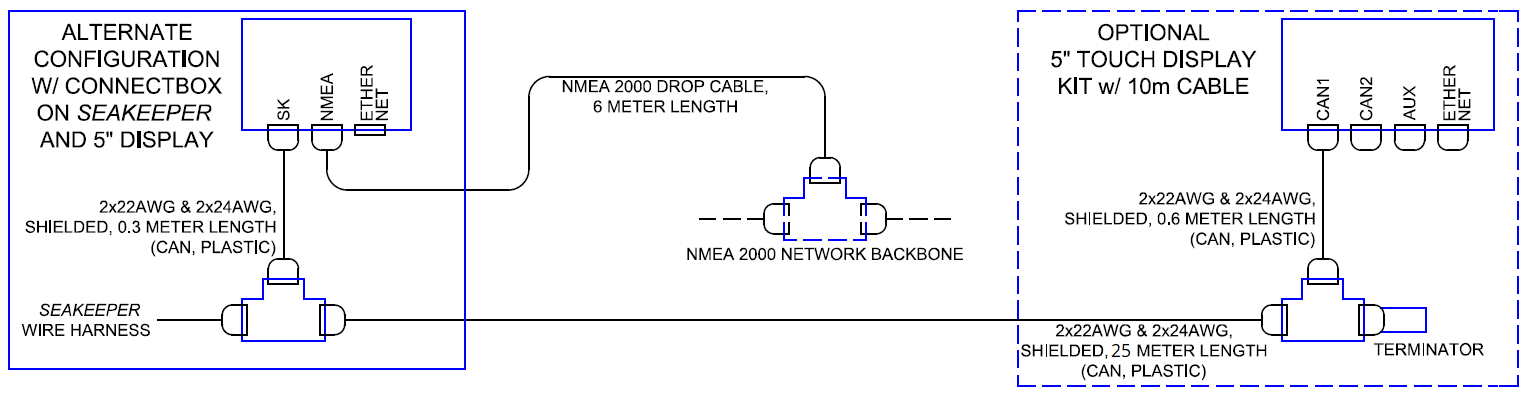

- Preferably, connect the Seakeeper 2 to a compatible Multifunction Display (MFD).

- Install an optional Seakeeper 5″ Touch Display.

- A combination of a compatible MFD and an optional 5″ Touch Display is also available, as seen in figure below (See drawing 90470).

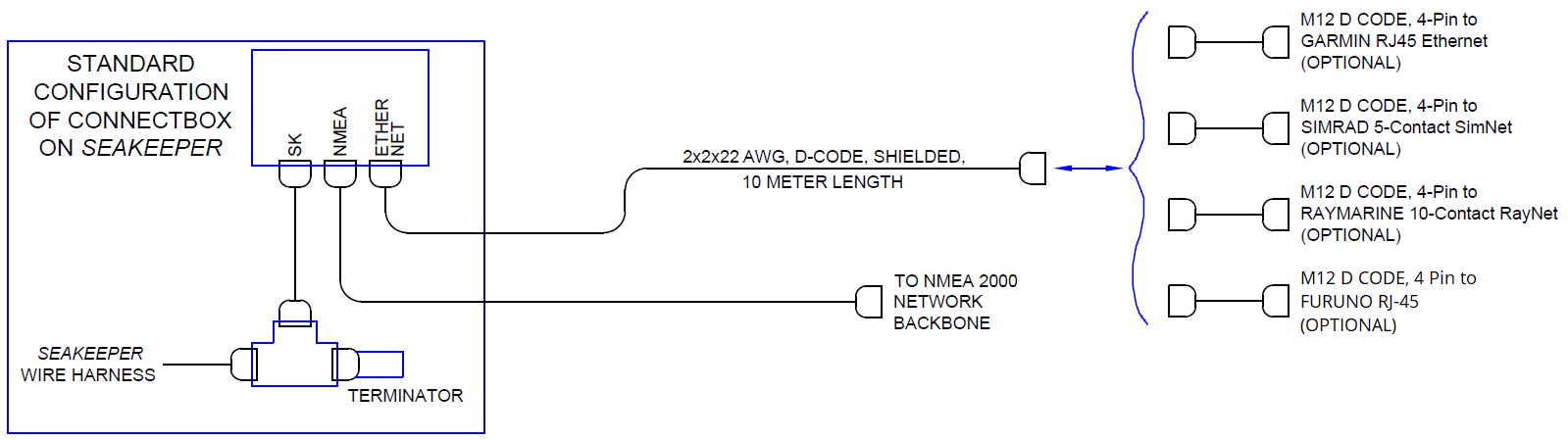

Figure 9 provides a schematic of the standard display option. The subsequent sections outline the instructions and references for connecting the Seakeeper 3 in each display option.

3.4.2 Connecting to Compatible MFD

- The Seakeeper 3 can be connected to a variety of available MFD systems. Refer to the Technical Bulletins Section of the Seakeeper Technical Library for manufacturer specific MFD compatibility technical Bulletins.

- MFD specific Technical Bulletins will be updated regularly as new MFD systems become compatible. Currently GARMIN, RAYMARINE, NAVICO (Simrad, Lowrance, and B&G), and FURUNO offer compatible MFD models.

- Once a compatible MFD has been selected, refer to the appropriate manufacturer specific Technical Bulletin for integration instructions and applicable adapter cable part numbers.

- Connect Seakeeper-supplied M12 D-Code Cable, 32.8 ft (10 m), (P/N 30330), to MFD manufacturer-specific Ethernet adapter cable. Custom Ethernet cables for specific MFD manufacturers are available through Seakeeper and must be purchased with the Seakeeper 3 if connecting to an MFD.

3.4.3 Installing the Optional Seakeeper 5″ Touch Display

- Determine location of Seakeeper 5” Touch Display (P/N 90467):

- The desired location of the 5” Touch Display must be determined with respect to the vessel’s arrangement.

- The 5” Touch Display should be located on or near the helm or another easily accessible location.

- Route CAN communications cable:

- The CAN Cable Assembly (P/N 30243), is a 82 ft (25 m) shielded cable that connects the Seakeeper to the 5” Touch Display.

- The CAN Cable must be routed and installed in the vessel from the Seakeeper wire harness CAN to the Tee Adapter at the Seakeeper 5” touch display.

- Install Seakeeper 5” Touch Display equipment per figure above:

- Console space required: Approx. 5.24” W x 3.70 H” (133 x 94 mm)

- Mounting Instructions, Surface Mount: see Envelope and Mounting Details, 5” Touch Display (90438) for details.

- CAN communications tee adapter and terminator mounting instructions:

- Console space required, Rear: Approx. 4 W x 3 H in. (102 x 76 mm).

- Rear mount on vessel console panel, within 2 ft (0.6 m) of Display.

- Hardware required: One mounting screw for 0.197 in. (5 mm) diameter mounting hole on Tee Adapter.

3.4.4 NMEA 2000 Network Connection

The Seakeeper 2 requires a connection to the vessel’s NMEA 2000 network backbone via a drop cable for access to the GPS signal. The Seakeeper 2 will monitor information on the NMEA network to support and optimize the performance of the Seakeeper 2. If no GPS signal is detected, a warning will appear on the Seakeeper display. The Seakeeper will not spool-down, but the operation of the unit will be limited until the GPS signal returns.

- Install customer-supplied NMEA 2000 Tee Adapter (space required: approximately 4 W X 3 H in. (102 X 76 mm).

- Connect NMEA Backbone to Tee Adapter. NOTE: NMEA drop cable can be no longer than 19.6 ft (6 m) in length.

- Connect Seakeeper-supplied NMEA cable (P/N: 30332) to the customer-supplied NMEA 2000 Tee Adapter on vessel’s NMEA 2000 backbone.

- An active NMEA 2000 compatible GPS signal is required on the vessel’s NMEA 2000 backbone to operate the Seakeeper 3.

- If no GPS signal is detected, a Speed Over Ground (SOG signal) warning will be present on the Seakeeper app. See TB-90640 for NMEA connectivity guidance.

- An active NMEA 2000 compatible GPS signal is required on the vessel’s NMEA 2000 backbone to operate the Seakeeper 3.

3.4.5 ConnectBox Helm Mounting – Optional

- Console space required: Approx. 3.41 L x 4.15 W in. (87 x 106 mm).

- Mounting Instructions, Surface Mount: See Drawing No. 90558 – ConnectBox Helm Mounting Kit, for details.

- Mount ConnectBox Replacement Blank insert into Seakeeper 3 enclosure at the original location of the ConnectBox.

4.0 Cooling Installation

4.1 Cooling Installation Introduction

Reference Documents:

- 90377 – Seakeeper 3 Cable Block Diagram

- 90376 – Seakeeper 3 Cooling Water Schematic

- TB-90191 – Seawater Cooling Pump Recommendations

- 30331 – Seakeeper DC Seawater Pump Assembly

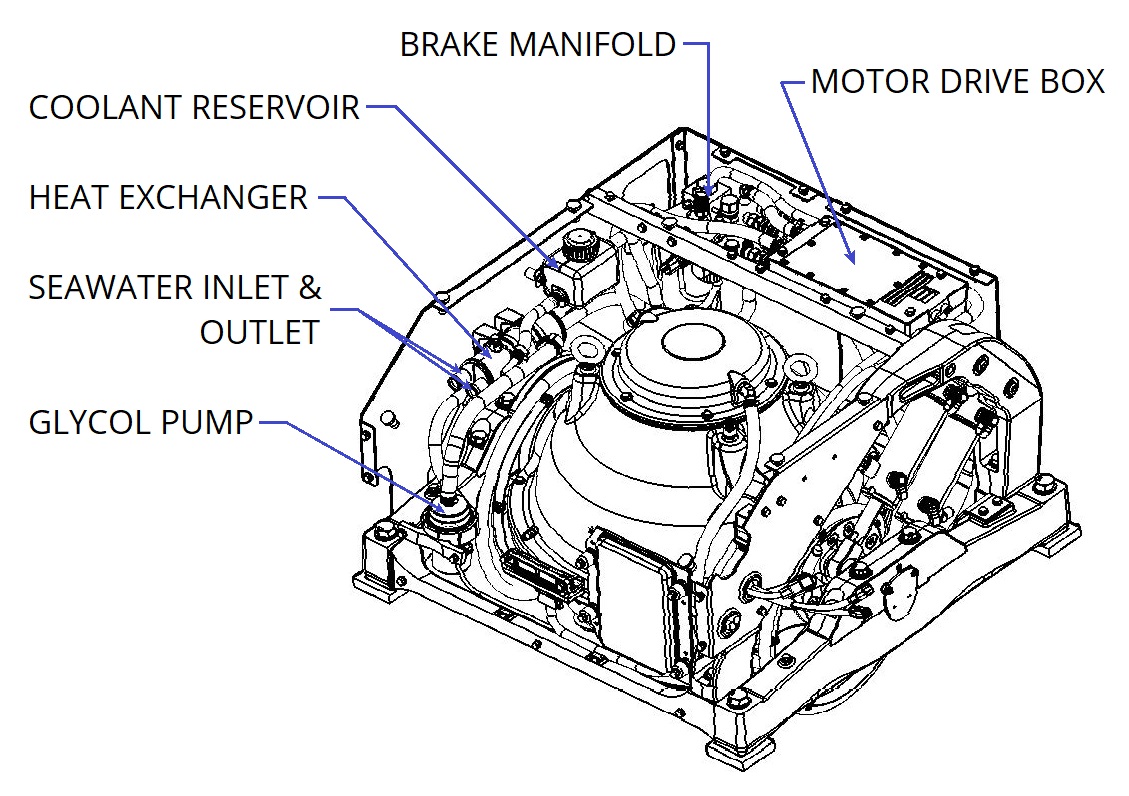

The Seakeeper 3 is shipped with the cooling circuit filled and ready for use. The Seakeeper 3 requires connection to a raw water pump, referred to as the seawater pump, to cool the closed loop cooling circuit on the unit. The required seawater flow through the Seakeeper 3 heat exchanger is between 2 – 6 GPM (7.6 – 22.7 LPM), under all vessel operating conditions. Prior to operation, confirmation of glycol level is required.

Seakeeper offers a compatible self-priming DC Seawater Pump (P/N 30331) that is prewired for the

Seakeeper 3 Installation and covered under the standard Seakeeper warranty. See Drawing No. 30331,

Seakeeper DC Seawater Pump Assembly for details and the Seakeeper Options and Accessories Price List for pricing information.

4.2 Installation Considerations

- Installer is responsible for supplying a dedicated seawater pump and associated plumbing. Seawater connections on the Seakeeper heat exchanger mate with ¾ in. (19mm) hose. An optional seawater pump can be purchased through Seakeeper, P/N30331.

- Seawater connections on the Seakeeper heat exchanger mate with 0.75 in. (19 mm) hose.

- The seawater pump operates on 12 VDC with a max overcurrent protection rating of 15 A.

- The seawater pump is powered by Cable 5, via “SW Pump 12 VDC Out” on the Seakeeper 3, as outlined in Electrical Installation Section.

- A dedicated through-hull fitting should be installed for each Seakeeper unit onboard the vessel to ensure sufficient seawater flow to each unit.

- It is recommended that the seawater pump is located below the waterline, as close to the baseline of the vessel as practically possible, to maintain positive inlet pressure on the pump in all operating conditions.

- A self-priming seawater pump may be required to maintain water flow in all underway conditions. Cavitation can occur at the seawater inlet and potentially cause an air-lock condition restricting seawater flow to the heat exchanger.

- Maximum allowed seawater pressure in heat exchanger is 20 psi (1.4 bar).

- Seawater flow requirement through heat exchanger is 2 GPM (7.6 LPM) minimum and 6 GPM (22.7 LPM) maximum under all operating conditions of the boat.

When sizing seawater pump, installer should factor in losses for raw water plumbing. In addition to initial operation at dock, new Seakeeper installations should be checked to be within the flow requirements while vessel is at speed. Flows higher than 6 GPM (22.7 LPM) could affect heat exchanger life. - Vented loops (Figure 2) are optional and should only be considered with centrifugal style pumps. Self-priming or positive displacement style pumps do not require a vented loop, this includes Seakeeper P/N 30331.

4.3 Connecting Seawater to Heat Exchanger

Refer to Figure 2 for typical seawater plumbing arrangement.

- Connect seawater pump to Seakeeper dedicated through-hull fitting. A strainer and seacock valve should generally be installed between the seawater inlet and the pump.

- Connect seawater from installer-supplied pump to lower ¾ in. (19 mm) hose barb onheat exchanger. Use the same practices as other below waterline seawater plumbing.

- Connect seawater discharge (upper hose barb) to overboard drain. Use the same practices as other below waterline seawater plumbing.

- Required flow rate is 2 GPM (7.6 LPM) minimum and 6 GPM (22.7 LPM) maximum.

- In addition to initial operation at dock, new Seakeeper installations should be checked for minimum 2 GPM (7.6 LPM) flow while vessel is at speed and when backing down.

- If no other method of confirming flow is available, discharge line may be temporarily diverted to a bucket. Flow is calculated from time to fill a known volume.

- A self-priming seawater pump (customer/installer supplied) may be required due to installation location to maintain water flow in all underway conditions where cavitation near the intake may occur and potentially cause an air-lock condition restricting seawater flow to the heat exchanger.

- Inspect raw water plumbing after sea trial for any signs of leakage.

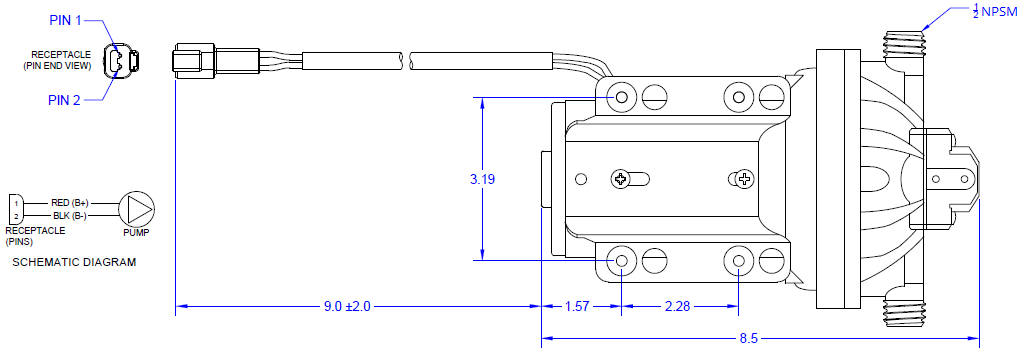

4.3.1 Seakeeper Optional DC Seawater Pump (P/N 30331)

- Seakeeper offers a self-priming DC Seawater pump as an optional addition, P/N 30331– DC Seawater Pump Assembly, shown in Figure 3.

- The Seakeeper Seawater Pump is a 24 VDC pump operated at 12 VDC for the Seakeeper 3 and maintains a seawater flow of approx. 2.5 GPM (9.5 LPM) at 12V DC.

- The pump assembly is pre-wired for connection to Seakeeper 3 Cable 5 and includes a seawater strainer and various fittings. The pump specifications are as follows:

| Voltage: | 24 VDC (Operate at 12 V for Seakeeper 3) |

| Rated Flow: | 2.5 GPM (9.5 LPM), at 12 VDC |

| Overcurrent Protection: | 15 A |

| Ignition Protection: | ISO 8846 or equivalent |

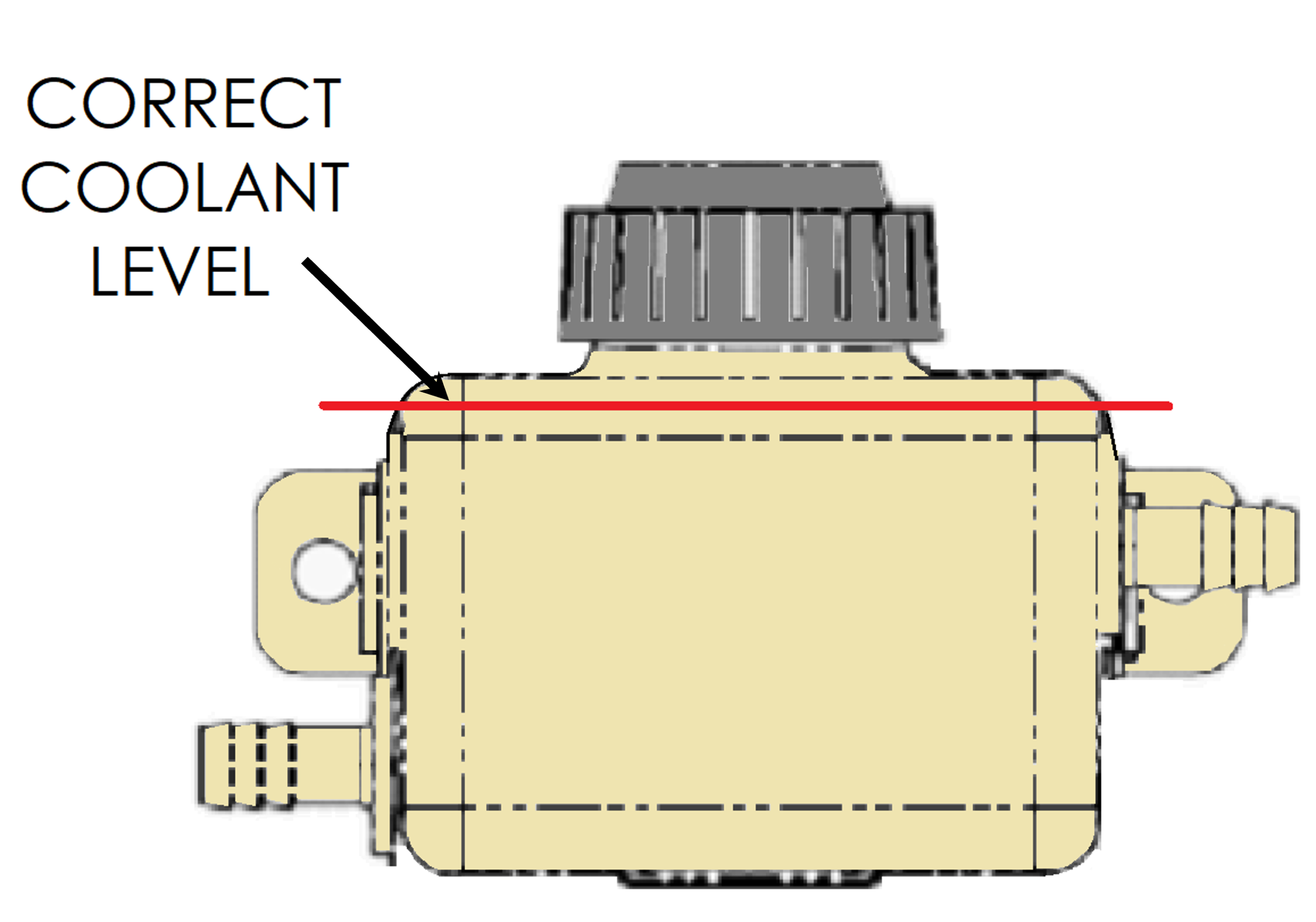

4.4 Adding Coolant

- The Seakeeper 3 cooling system is filled to proper level when shipped. If level has dropped, check for evidence of leaks at all connections before adding fluid as described below. If coolant is at the correct level, skip to Step 5.

- The minimum and maximum glycol levels are shown in Figure 4.

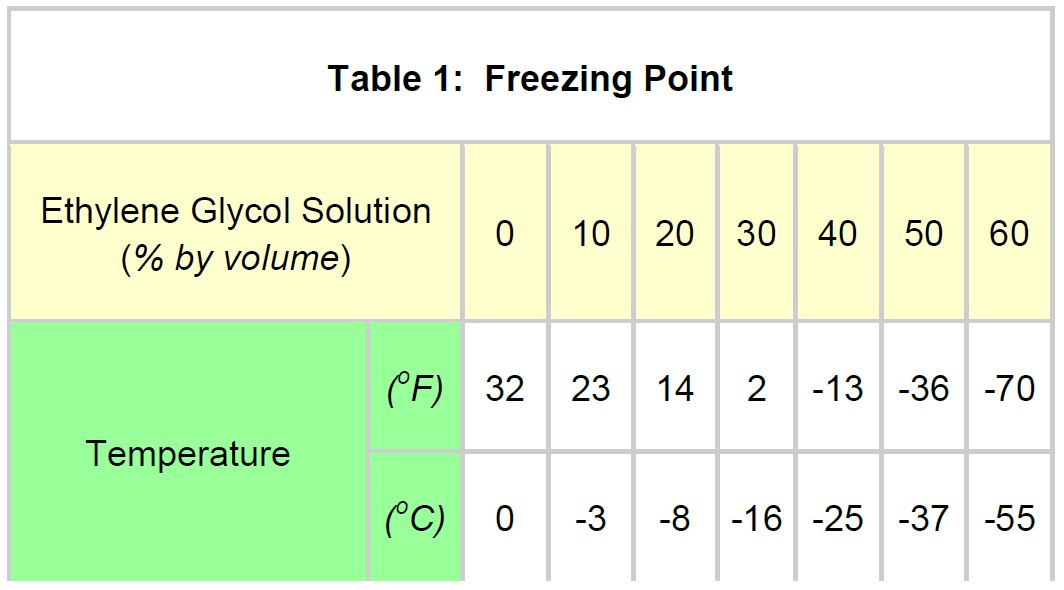

- Mix 50% ethylene glycol with 50% distilled water in a clean container. Refer to Table 1or glycol manufacturer’s literature for freezing points.

- It is required that ethylene glycol with corrosion inhibitors be used. Most commercially available glycol has these additives standard.

- Remove reservoir cap and pour mixture in until level reaches top face of the reservoir enclosure, as shown in Figure 4.

- Filling reservoir above this level will not cause any damage but coolant may be expelled from pressure relief port in cap due to normal thermal expansion of coolant.

- Once the Seakeeper 3 and DC seawater pump are connected to 12 VDC power:

- At the MFD or Display check for any ALARMS.

- Cycle the Seakeeper 3 power, and Press the POWER ON button.

- The flywheel will start to spin and the glycol pump will start on demand.

- Recheck glycol level with fluid circulating in coolant circuit. Inspect reservoir to check coolant level is above minimum level of Figure 4. Replace cap if removed.

- After several minutes of running, press POWER OFF button to turn power off to the Seakeeper.

- The cooling system is self-purging. If small amounts of air are in the system, they will most likely be dislodged during the first sea trial. Recheck level after sea trial and add fluid if required.

NOTE: It is not uncommon to see some air in the coolant system. It is normal and will not affect operation.

5.0 Installation Requirements

5.1 Installation Requirements Introduction

The Installation Requirements section outlines the components and tools needed for the Seakeeper 3 Installation that are not included within the scope of supply. Seakeeper offers Core Installation Kits which provide the required components for DC Seakeeper installations. These kits are outline in the DC Installation Kits Technical Bulletin (TB-90575).

5.2 Required Supplies for Seakeeper Installation

Table 1 outlines the customer-supplied components required for the Seakeeper 3 installation:

Table 1: Components and Supplies Required for Seakeeper 3 Installation

| Item | Description | QTY | Installation Manual Reference Section | Other Reference | System |

| 1 | Spreader bar for lifting the Seakeeper | 1 | Transport & Unpacking | P/N 11766 | Mechanical |

| 2 | Seakeeper 3 Fixture Kit | 1 | Bolt-In Installation | P/N 90362 | Mechanical |

| 3 | Threaded insert M16-2 (24 mm) | 4 | Bolt-In Installation | Dwg 90374 | Mechanical |

| 4 | Seakeeper 3 Bolt-In Kit | 1 | Bolt-In Installation | P/N 90375 | Mechanical |

| 5 | Seakeeper 3 Thru-Bolt Kit | 1 | Bolt-In Installation | P/N 90641 | Mechanical |

| 6 | Marine Sealant | AR | Bolt-In Installation | Dwg 90374 | Mechanical |

| 7 | Nickel-based Anti-seize | AR | Bolt-In Installation | Dwg 90374 | Mechanical |

| 8 | Circuit Breaker, 100A (Cable 1) | 1 | Electrical Equipment Power Connections | Dwg 90377 | Electrical |

| 9 | Circuit Breaker, 15 A (Cable 7 & 8) | 2 | Electrical Equipment Power Connections | Dwg 90377 | Electrical |

| 10 | Battery Isolator Switch (Cable 1, 7, & 8) | 1 | Electrical Equipment Power Connections | Dwg 90377 | Electrical |

| 11 | M6 terminal lug for grounding Seakeeper | 1 | Electrical Equipment Ground Connections | Dwg 90377 | Electrical |

| 12 | Cable, 4 AWG, for grounding Seakeeper at rear brace to vessel ground (Cable 6, used with item 11) | 1 | Electrical Equipment Ground Connections | Dwg 90377 ABYC E-11 | Electrical |

| 13 | Seawater pump, 12VDC, 15 A max Optional: DC Seawater Pump Assembly (pre-wired) | 1 | Electrical Equipment Power Connections | Dwg 90377 P/N 30331 | Electrical / Cooling |

| 14 | Seakeeper 5″ Touch Display and Optional Compatible MFD | 1 | Electrical Equipment Power Connections | Dwg 90377 TB-90640 / P/N90600 | Electrical |

| 15 | Through-hull fittings (1 high-speed pick-up / 1 overboard discharge) | 2 | Connecting Seawater to Heat Exchanger | Dwg 90376 | Cooling |

| 16 | Seawater Strainer *included with Seakeeper Seawater Pump(P/N 30331) | 1 | Connecting Seawater to Heat Exchanger | Dwg 90376 | Cooling |

| 17 | Seacock Valve | Connecting Seawater to Heat Exchanger | Dwg 90376 | Cooling | |

| 18 | 3/4 in. (19 mm) ID Seawater Suction Hose AND Discharge Hose | AR | Connecting Seawater to Heat Exchanger | Dwg 90376 | Cooling |

| 19 | Hose clamps for seawater plumbing to ¾ in. (19 mm) hose barb (2 per hose barb) | 4 | Connecting Seawater to Heat Exchanger | Dwg 90376 | Cooling |

AR = As Required

Dwg = Drawing

5.3 Tools Required for Installation

Table 2 outlines the tools and equipment required for the Seakeeper 3 installation:

Table 2: Tools Required for Installation

| Item | Description | Use |

| 1 | Hoist, Forklift, or Crane | Unpacking and lifting Seakeeper 3 into position |

| 2 | Transfer Punch Kit | Locate foundation hole penetrations |

| 3 | Drill / Drill Press | Bolt hole penetrations |

| 4 | Threaded Insert Installation Kit | Tap and install threaded inserts (M14-2 X 1.5 X Dia.) |

| 5 | Flexible Extendable Magnet, McMaster P/N: 3838A42 or similar | Lowering foundation bolts into place |

| 6 | 1/2″ Drive Torque Wrench | Foundation Bolts (155 ft-lbs/210 Nm) |

| 7 | 12 – 18″ Extension, 1/2″ Drive | Foundation Bolts |

| 8 | 24mm Socket, 1/2″ Drive | Foundation Bolts |

| 9 | Utility Knife | Scoring Cable Jackets |

| 10 | Wire cutter | DC Power cables |

| 11 | Wire stripper | DC Power cables |

| 12 | Greenlee K05-Synchro Crimp Tool or equivalent | 12 VDC High-Current Input Cables, 2AWG Ground Cable, 4 AWG |

| 13 | Heat Gun | For cables 1, 2, and 6 heat shrink |

| 14 | ¼ in. (7mm) Nut Driver / Flat Head Screwdriver | Hose clamps |

| 15 | Fish Tape | Cable Pulls |

| 16 | Hole Saw | Thru-hull fittings |

NOTE: Additional tools may be required for the installation of customer supplied components.

6.0 Installation & Start Up Checklist

6.1 Installation & Start Up Introduction

Reference Documents:

The Installation and Start Up Checklists in this section provide an overview of the primary steps covered in the installation manual and should be referenced throughout the installation process. Upon completion of the

Seakeeper 3 installation, the installer should commission each Seakeeper unit with the Seakeeper Commissioning Form (90437). The Commissioning Checklist Work Instruction (SWI-105) provides a checklist of items to inspect and verify during the commissioning process and serves as a supplement to the Seakeeper Commissioning Form (90437).

All Seakeeper stabilizers should be commissioned to verify installation specifications and requirements have been implemented properly. The commissioning process should include completion of the Seakeeper

Commissioning Form (90437), all the items in the Installation Checklist, and verification of Seakeeper 3 operation without alarms or abnormal behavior.

6.2 Installation Checklist

6.2.1 Mechanical Checklist

| CHECK | REQUIREMENT TO BE MET |

| Seakeeper foundation installed per requirements of the Seakeeper 3 Bolt-in Installation Details. * Structure designed to accommodate Seakeeper 3 forces, as defined in Drawing No. 90374 with a minimum safety factor of 3.0. * Foundation is co-planar within 0.06″ (1.5 mm). | |

| Clearances around Seakeeper meet service and operating specifications and no obstructions are within the Seakeeper envelope. | |

| Seakeeper 3 Bolt-In Kit (P/N 90375) or Through-bolt Kit (P/N 90641) is installed with a minimum thread engagement of 0.8″ (20.42 mm) or bolt passing entirely through backing nut. * If longer mount bolts are required, they should match the M16-2.0, Grade10.9 specification provided. Stainless steel mounting bolts cannot be used for the Seakeeper 3. | |

| Foundation bolts torqued to specification: 155 ft-lbs (210 Nm). | |

| Seakeeper 3 cover can be removed to access and service the unit. |

6.2.2 Electrical Checklist

6.2.2.1 High Current 12 VDC Power Source, Cable 1 & 2

| CHECK | REQUIREMENT TO BE MET |

| Connect cable 1 and 2 to customer supplied 2 AWG B+ and B- conductors to allow for routing to 12 VDC power source. * Connect Cable 1, B+ conductor (red) through 100 A circuit breaker(customer-supplied) and a dedicated battery isolation switch (customer-supplied), directly to the battery positive terminal or bus bar. * Connect Cable 2, B- conductor (black), to battery negative terminal or DC negative bus bar. | |

| If the 2 AWG high-current 12V power input conductors are shortened or lengthened, use heavy-duty eyelet (closed end) terminals such as Molex19221-0235. |

6.2.2.2 Low Current 12 VDC Power Source, Cable 7

| CHECK | REQUIREMENT TO BE MET |

| Connect Cable 7 positive (red) directly to a customer-supplied 15 A circuit breaker, then to the dedicated battery isolation switch | |

| Connect Cable 7 negative (black) to the DC negative bus bar or battery negative terminal. | |

| Plug Cable 7 connector end into the DT-Series connector labelled Low-Current 12 VDC in connector on the Seakeeper wire harness. |

6.2.2.3 Seawater Pump Connection, Cable 8 & 5

| CHECK | REQUIREMENT TO BE MET |

| Connect Cable 8 positive (red) directly to a customer-supplied circuit breaker corresponding to the seawater pump overcurrent protection rating (max 15 A), then to the dedicated battery isolation switch. | |

| Connect Cable 8 negative (black) to the DC main negative bus bar or battery negative terminal. | |

| Connect Cable 5 receptacle end (pins) to Seakeeper SW Pump 12 VDC Out and the plug end (sockets) to customer-supplied 12 VDC seawater pump cable Deutsch connector termination. |

6.2.2.4 Ground Connection, Cable 6

| CHECK | REQUIREMENT TO BE MET |

| Install lugs on both ends of customer-supplied 4 AWG ground cable. | |

| Connect one end of Cable 6 to nearest vessel ground and other end to ground stud on Seakeeper frame. | |

| Vessel grounding bus to comply with: * EM/IEC 60204-1 Clauses 6.3.3 and 8.2.3 * ABYC E-11 July 2018 Clauses 11.5.2 and 11.16.1. |

6.2.3 Cooling Checklist

| CHECK | REQUIREMENT TO BE MET |

| Purchase seawater pump for Seakeeper 3 to provide 2 – 4 GPM (7.6 – 15.1LPM) with a max overcurrent protection rating of 15 A. Optional seawater pump can be purchased through Seakeeper, P/N 30331. | |

| Connect and route 3/4″ (19 mm) seawater inlet hose from seacock valve to the seawater strainer, seawater pump, and then to the Seakeeper 3 heat exchanger inlet. | |

| Connect and route 3/4″ (19 mm) seawater outlet hose from Seakeeper 3 heat exchanger outlet to the seawater overboard. | |

| Test seawater pump: * Verify 2 GPM (7.6 LPM) minimum and 4 GPM (15.1 LPM) maximum seawater flow through heat exchanger under all operating conditions of the vessel. | |

| Verify coolant level in heat exchanger coolant reservoir, fill if needed. |

6.3 Start-Up Checklist

Refer to Seakeeper 3 Operation Manual, Startup Section for detailed start-up instructions.

Prior to beginning the start-up sequence all previous Sections of the Installation Manual for Mechanical, Electrical, and Cooling installation must be complete. Before continuing, the Seakeeper 3 cover must be installed, and the operating clearances must be clear of personnel and equipment

| CHECK | REQUIREMENT TO BE MET |

| Remove lifting eyebolts and install sealing bolts and washers into lifting eyeholes and install cover. | |

| Energize battery isolation switch, high-current 110 A breaker, low-current 15 A breaker, and seawater pump breaker. | |

| Verify Seakeeper display is active and no alarms present. * If the Seakeeper 3 display does not activate, turn off all circuit breakers immediately and check all wiring connections. | |

| Check that battery voltage exceeds 12 VDC. A minimum battery voltage of11.2 VDC is required for the duration of Seakeeper spool-up. | |

| Override seawater pump “ON” (at 0 RPM hold down SERVICE button (wrench icon) for 5 seconds) and verify flow at seawater outlet. | |

| Press Seakeeper ON/OFF Button and follow instructions in Seakeeper 3 Operation Manual, Section 2 for complete start-up instructions. | |

| Verify no alarms are present. | |

| Power Seakeeper 3 down, the Seakeeper 3 flywheel will take 2+ hours to coast down to 0 RPM. |

7.0 Revision History

| Revision | Description | Date |

| 6 | Pre-ConnectBox Launch update. Thru-Bolt Installation added. Bolt-in kit changes. Cooling water system update. | 17FEB2023 |