Seakeeper 2 Installation Manual (90488-3); S/N 2-203-0400 to 2-232-1563

Mechanical Installation

Mechanical Installation Introduction

The Seakeeper 2 is capable of producing loads up to 1,459 lbs (6.49 kN) at each of the four mounts and careful consideration should be given to foundation design to insure it is capable of transferring these loads into the hull. These loads do NOT include vessel motion accelerations, such as vertical slam loads which can be high for higher speed vessels. Seakeeper suggests a safety factor of 3.0 (yielding a safety margin of 2.0).

There are two methods of installing the Seakeeper 2:

1. Longitudinal Bolt-In Installation

2. Transverse Bolt-In Installation

It is assumed that the installer is familiar with mounting using mechanical fasteners to marine structures and has performed structural analysis to assure the structure to which the Seakeeper mounts can properly transfer the loads the Seakeeper creates into the hull structure. If the installer has any doubt about the ability of the structure to transfer the loads to the hull then the installer should contact a licensed naval architect or marine engineer to do a structural analysis.

The installer should review the following list of reference drawings to ensure the installation procedure is fully understood.

Reference Documents & Drawings:

Link to Seakeeper 2 Reference Documents

- 90469 – Seakeeper 2 Hardware Scope of Supply

- 90487 – Seakeeper 2 Installation Details – Bolt in Method

- 90490 – Seakeeper 2 Cooling Water Schematic

- 90473 – Seakeeper 2 Installation Template Kit

- 90470 – Seakeeper 2 Cable Block Diagram

Precautions

- The Seakeeper must only be lifted from the supplied lifting eyes (see Section: Transport and Unpacking).

- The Seakeeper flywheel is supported by precision bearings. Make certain while unpacking and lifting the Seakeeper assembly to NOT drop or impart mechanical shock as damage to bearings could result.

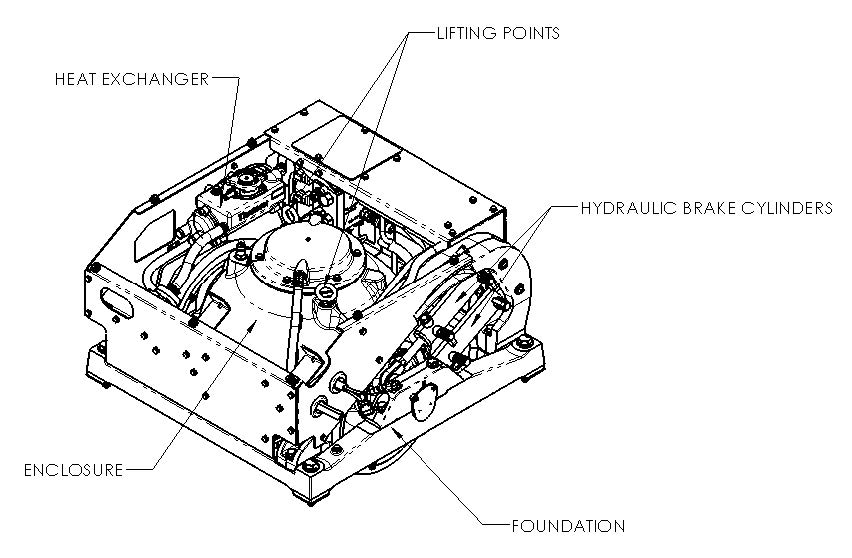

- While handling / installing the Seakeeper assembly, protect exposed hydraulic brake cylinder rods (See Figure 1) from scratches or damage as this could lead to premature seal failure and oil leaks.

- While handling / installing the Seakeeper assembly, do not allow electrical fittings that exit bottom of the Seakeeper enclosure to come in contact with any surface or object as this could damage the fittings and potentially affect the vacuum integrity of the enclosure.

- Exercise care to protect the painted finish as damage to finish could lead to early appearance degradation of the installed Seakeeper.

Selection of Installation Location

Selection of mounting location of the Seakeeper should consider the following desirable features:

The Seakeeper should be installed aft of amidships to minimize high acceleration loadings due to hull/wave impacts during operation at high speed or in large waves. If the only possible Seakeeper location is forward of amidships then the installer should have Seakeeper review the installation location prior to finalizing the design.

- Top down access or sufficient clearance for removal / re-installation of the Seakeeper for overhaul in future years.

- The Seakeeper should be installed in a dry space to minimize effects of corrosion.

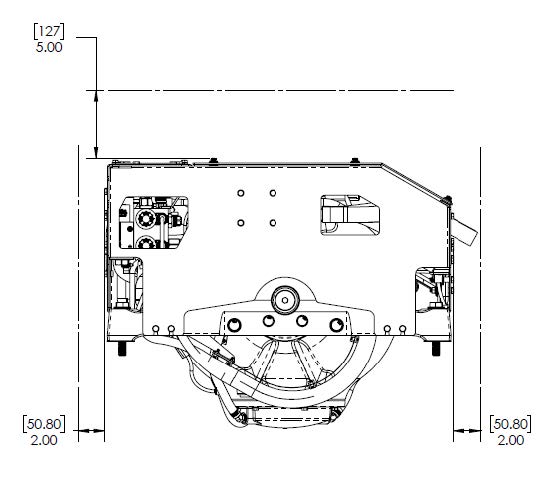

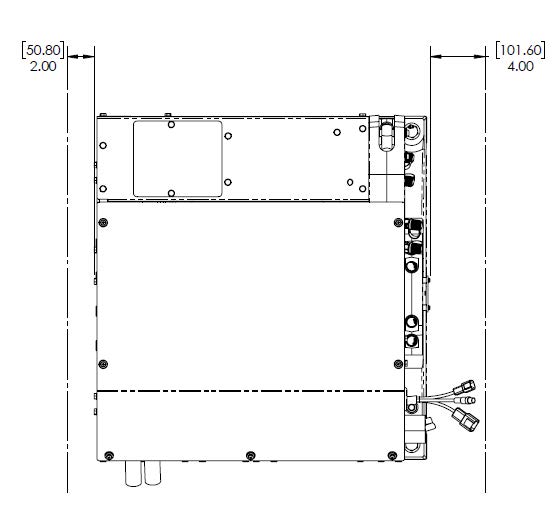

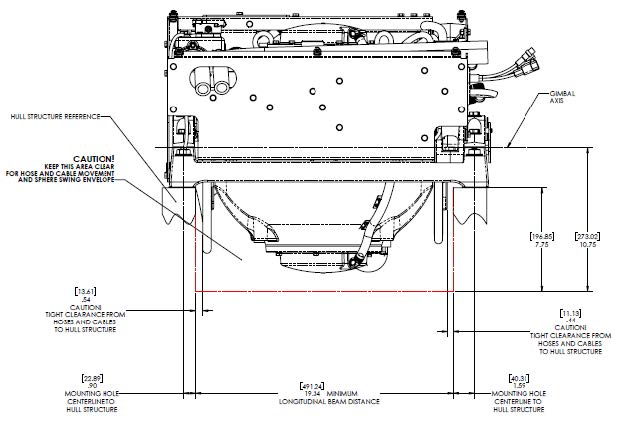

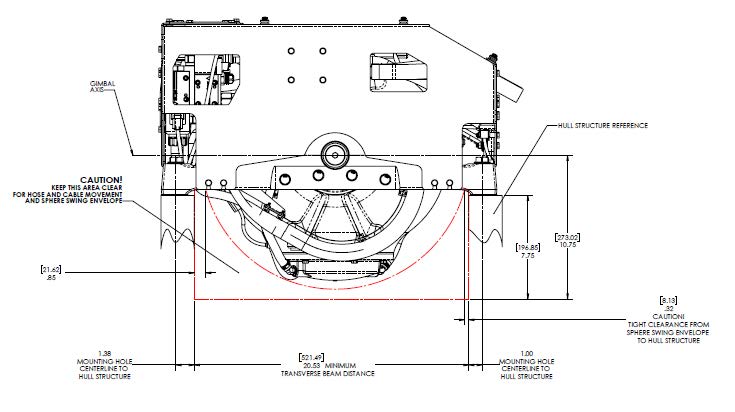

- Clearance for all recommended scheduled maintenance and any repairs that may be necessary (see Figure 2).

VIEWS SHOWING RECOMMENDED CLEARANCES AROUND THE SEAKEEPER FOR USE OF HANDTOOLS, EASE OF MAINTENANCE, INSTALLATION, AND PROPER OPERATION.

Figure 2 – Seakeeper 2 Installed Clearance Considerations

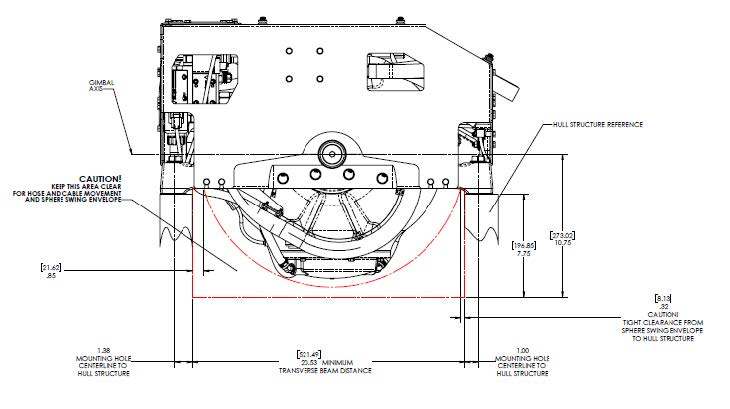

Refer to Figure 3 for recommended clearances to transverse or longitudinal beams. Clearances aft of the Seakeeper are shown to provide access for regular scheduled maintenance.

Safety

There is a large torque about the gimbal axis when the Seakeeper is precessing. Seakeeper cover panels are provided to prevent personnel or equipment from contacting the Seakeeper while it is in operation. These covers should not be stepped on or have anything placed on top. The covers should always be in place during operation. If it is ever necessary to access the Seakeeper while the flywheel is spinning, the Seakeeper must be locked at the display to stop the Seakeeper from precessing. Seakeeper regular scheduled maintenance should not be attempted unless the Seakeeper is locked and the flywheel has stopped spinning.

The Seakeeper should be treated with the same respect one gives a high speed rotating propeller shaft or engine shaft.

Noise/Soundproofing

Seakeeper noise has been measured under steady state conditions (no wave load) in Seakeeper‘s Engineering Lab and in our Factory Demo Boat. The steady state noise at 1 meter is typically in the range of 64-68 dBC un-weighted. As the frequencies emitting the highest sound pressures are low (like other marine machinery), it is recommended that the Seakeeper be installed in a machinery space that is already treated with soundproofing.

Transport and Unpacking

Transport

- Use a Seakeeper provided shipping crate for transport, P/N 11851. Overall dimensions of a fully packed crate are 36.25 L x 35.75 W x 38 H in. (0.92 L x 0.91 W x 0.97 H m) with a weight of 482 lbs (219 kg).

- Do not stack Seakeeper shipping crates.

- Both Air and Ground transport are acceptable.

- Seakeeper shipping crates must be transported in environmental conditions between -4°F and 140°F (-20°C and 60°C).

Unpacking Crate

- Reference Seakeeper Drawing No. 90469 – Seakeeper 2 Hardware Scope of Supply, for items that ship with the corresponding Seakeeper model.

- Remove covers, electrical components, display, cables, and misc. items and set aside.

- Remove packing materials that secure Seakeeper assembly inside the crate.

- Attach spreader bar (P/N 11766; available for purchase) to the two lifting eyes located on the top of the Seakeeper enclosure. Stay clear of any other parts on the Seakeeper. The Seakeeper 2 weighs 414 lbs (188 kg). See Figure 4 below.

Longitudinal Bolt-In Installation

Check and Preparation of Hull Structure

The Seakeeper 2 can be affixed to the hull structure using two methods 1) Longitudinal Beam Bolt-In installation or 2) Transverse Beam Bolt-In installation. Neither option affects the operation of the Seakeeper. However, one option might ease the installation process or allow for a larger service envelope. Depending on the structure to which the Seakeeper is fastened, blind threaded holes or thru-bolting can be utilized.

Refer to Seakeeper Drawing No. 90487 – Seakeeper 2 Installation Details – Bolt in Method. Important dimensional and load information is given in this drawing that will impact the design details of the structure that will receive the Seakeeper. It is assumed that a proper structural analysis has been performed for the hull structure to which the Seakeeper will be fastened to ensure proper strength margins for the loads the Seakeeper will create during operation.

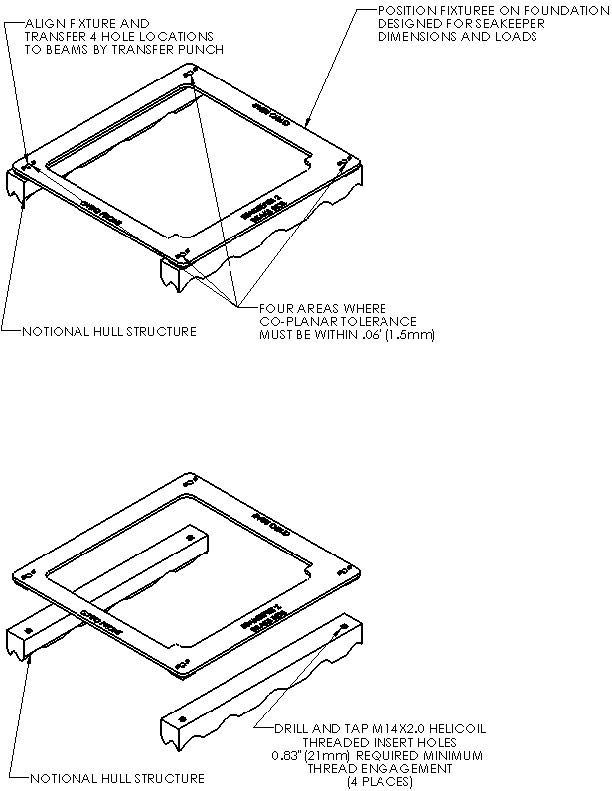

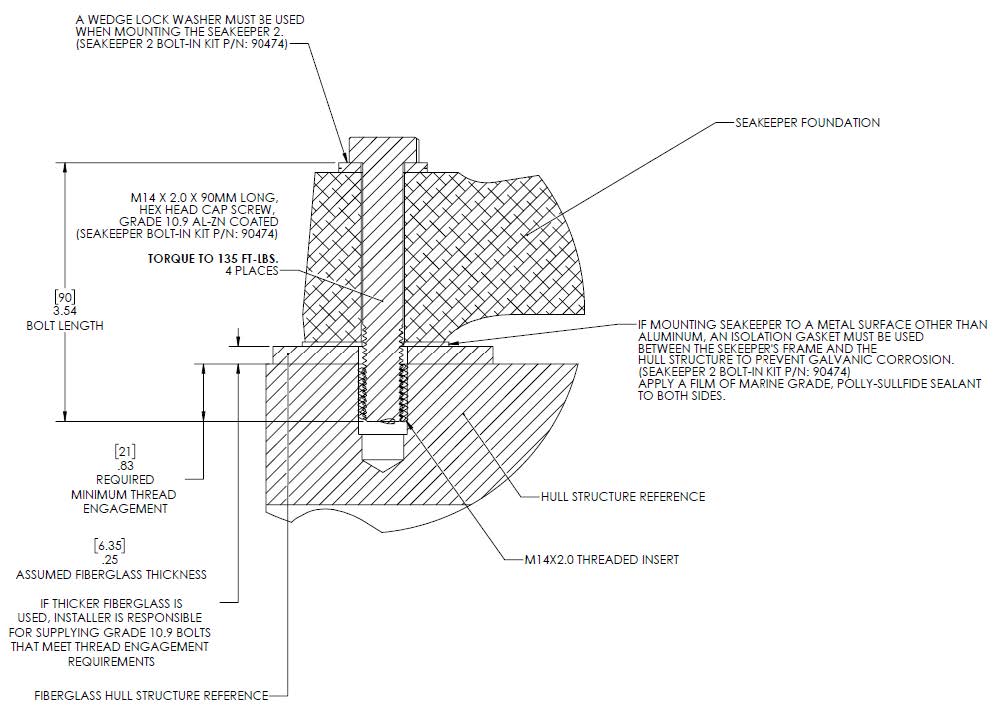

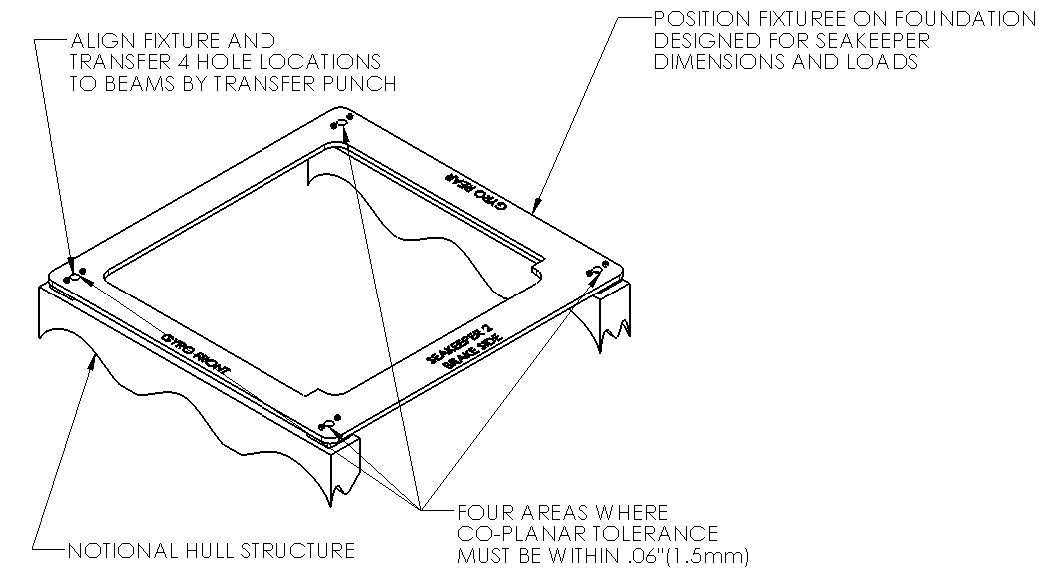

The hull structure supporting the Seakeeper should be installed so the Seakeeper is parallel to the waterline. In addition, the four areas on top of the beams on which the feet of the Seakeeper foundation and isolation gaskets will rest, need to be co-planar within .06 in. (1.5 mm) to minimize potential distortion of Seakeeper support frame when installed. The isolation gaskets are only used on dissimilar metal to metal contacts.

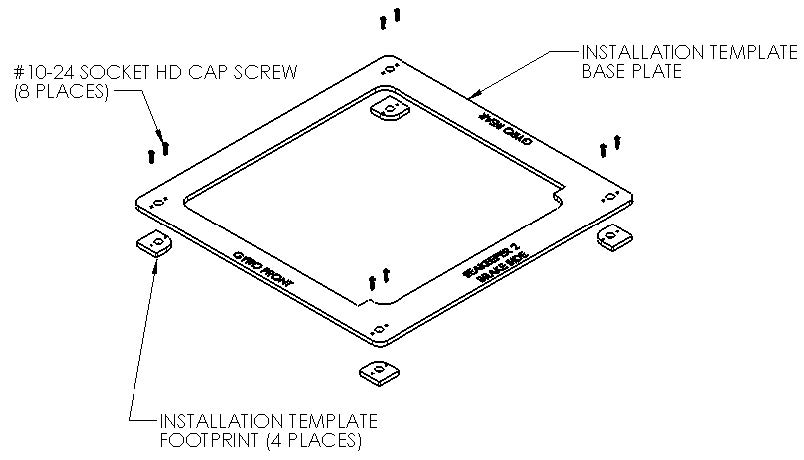

Seakeeper offers an optional installation template kit, P/N 90473, which contains four plates that mimic the mating surfaces of the four feet located on the Seakeeper’s foundation. These plates have 4 holes located at the same centers as the mounting holes on the Seakeeper. The fixture locates the hole patterns at the proper spacing both in the forward-aft direction and the port-starboard direction. See Figure 5 below. Once assembled, the fixture can be used to check clearances and alignment of the hull structure.

Note: Do NOT use the installation fixture to establish the Seakeeper envelope dimensions. Refer to Drawing No. 90487 – Seakeeper 2 Bolt-In Installation Details, for envelope dimensions. A 3-D model of the Seakeeper is available on the Seakeeper website (www.seakeeper.com) to aid in designing the Seakeeper foundation and the space around the Seakeeper.

NOTE: MAKE SURE NO OBSTRUCTIONS FROM THE HULL STRUCTURE CAN BE SEEN WITHIN THE INSIDE OF THE INSTALLATION TEMPLATE KIT (INSIDE THE MARKED RED LINES). REFERENCE SEAKEEPER DRAWING NO. 90487 – SEAKEEPER 2 BOLT-IN INSTALLATION DETAILS.

CAUTION: Tight clearances from cable guide bands to hull structure. See above figure for dimensions and reference Seakeeper Drawing No. 90487 – Seakeeper 2 Bolt-In Installation Details, for complete Seakeeper 2 envelope.

Transfer of Holes to Boat Structure

- Lower assembled fixture onto hull structure.

- The four areas where the feet of the Seakeeper will rest should be coplanar to within .06 in. (1.5 mm). See Figure 7.

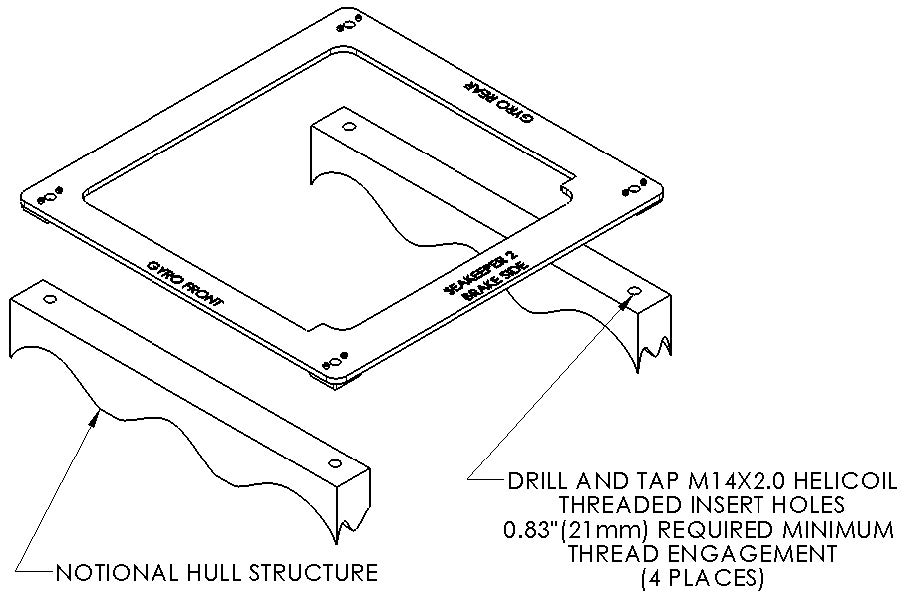

- Align fixture in desired location and transfer holes from fixture plate to the hull structure. Note that holes in fixture plate are ø0.60 in. (15.138 mm).

- Remove fixture and drill and tap M14X2.0 Helicoil threaded insert holes in hull structure at marked locations to mate with holes in the Seakeeper foundation. Take special care to drill perpendicular to mounting surface. A drill guide is recommended. Remove any impeding obstructions.

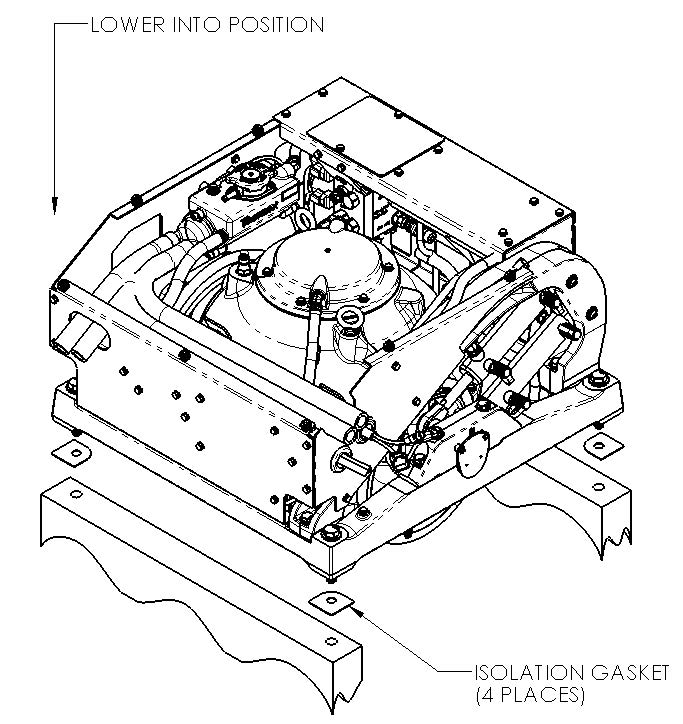

Installation of Seakeeper

- Locate and position 4 isolation gaskets onto foundation beams (for metal to metal contacts only). NOTE: Sealant or caulk is recommended to be applied. Apply a small bead (approximately 4 mm wide) of sealant (silicone or caulk) between both mating surfaces of each isolation gasket where it contacts the beam and the Seakeeper. This will prevent water from wicking between the parts and setting up corrosion. Check isolation gasket alignment by test fitting bolts without any obstructions.

- Lower Seakeeper into position onto the hull foundation beams and align over drilled holes.

- Install Seakeeper supplied M14 fasteners Or Grade 10.9, M14-2.0 bolts to maintain a minimum thread engagement of .83 in. (21 mm) – apply a moderate coat of removable thread locker to the threads of each bolt and include a small bead of sealant under each washer before installation.

- Torque all fasteners to 135 ft-lbs (183 N-m). New Seakeeper supplied bolts must be used for each installation and reinstallation.

- Proceed to electrical and cooling portion of the installation.

Transverse Bolt-In Installation

Check and Preparation of Hull Structure

The Seakeeper 2 can be affixed to the hull structure using two methods 1) Longitudinal Beam Bolt-In installation or 2) Transverse Beam Bolt-In installation. Neither option affects the operation of the Seakeeper. However, one option might ease the installation process or allow for a larger service envelope. Depending on the structure to which the Seakeeper is fastened, blind threaded holes or thru-bolting can be utilized.

Refer to Seakeeper Drawing No. 90487 – Seakeeper 2 Bolt-In Installation Details. Important dimensional and load information is given in this drawing that will impact the design details of the structure that will receive the Seakeeper. It is assumed that a proper structural analysis has been performed for the hull structure to which the Seakeeper will be fastened to ensure proper strength margins for the loads the Seakeeper will create during operation.

The hull structure supporting the Seakeeper should be installed so the Seakeeper is parallel to the waterline. In addition, the four areas on top of the beams on which the feet of the Seakeeper foundation and isolation gaskets will rest, need to be co-planar within .06 in. (1.5 mm) to minimize potential distortion of Seakeeper support frame when installed. The isolation gaskets are only used on dissimilar metal to metal contacts.

Seakeeper offers an optional installation template kit, P/N 90473, which contains four plates that mimic the mating surfaces of the four feet located on the Seakeeper’s foundation. These plates have 4 holes located at the same centers as the mounting holes on the Seakeeper. The fixture locates the hole patterns at the proper spacing both in the forward-aft direction and the port-starboard direction. See Figure 10 below. Once assembled, the fixture can be used to check clearances and alignment of the hull structure.

Note: Do NOT use the installation fixture to establish the Seakeeper envelope dimensions. Refer to Drawing No. 90487 – Seakeeper 2 Bolt-In Installation Details, for envelope dimensions. A 3-D model of the Seakeeper is available on the Seakeeper website (www.seakeeper.com) to aid in designing the Seakeeper foundation and the space around the Seakeeper.

NOTE: MAKE SURE NO OBSTRUCTIONS FROM THE HULL STRUCTURE CAN BE SEEN WITHIN THE INSIDE OF THE INSTALLATION TEMPLATE KIT (INSIDE THE MARKED RED LINES). REFERENCE SEAKEEPER DRAWING NO. 90487 – SEAKEEPER 2 BOLT-IN INSTALLATION DETAILS.

CAUTION: Tight clearances from cable guide bands to hull structure. See above figure for dimensions and reference Seakeeper Drawing No. 90487 – Seakeeper 2 Bolt-In Installation Details, for complete Seakeeper 2 envelope.

Transfer of Holes to Boat Structure

- Lower assembled fixture onto hull structure.

- The four areas where the feet of the Seakeeper will rest should be coplanar to within .06 in. (1.5 mm). See Figure 12.

- Align fixture in desired location and transfer holes from fixture plate to the hull structure. Note that holes in fixture plate are ø0.60 in. (15.138 mm).

- Remove fixture and drill and tap M14X2.0 Helicoil threaded insert holes in hull structure at marked locations to mate with holes in the Seakeeper foundation. Take special care to drill perpendicular to mounting surface. A drill guide is recommended. Remove any impeding obstructions.

Installation of Seakeeper

- Locate and position 4 isolation gaskets onto foundation beams (for metal to metal contacts only). NOTE: Sealant or caulk is recommended to be applied. Apply a small bead (approximately 4 mm wide) of sealant (silicone or caulk) between both mating surfaces of each isolation gasket where it contacts the beam and the Seakeeper. This will prevent water from wicking between the parts and setting up corrosion. Check isolation gasket alignment by test fitting bolts without any obstructions.

- Lower Seakeeper into position onto the hull foundation beams and align over drilled holes.

- Install Seakeeper supplied M14 fasteners Or Grade 10.9, M14-2.0 bolts to maintain a minimum thread engagement of .83 in. (21 mm) – apply a moderate coat of removable thread locker to the threads of each bolt and include a small bead of sealant under each washer before installation.

- Torque all fasteners to 135 ft-lbs (183 N-m). New, Seakeeper supplied bolts must be used for each installation and reinstallation.

- Proceed to electrical and cooling portion of the installation.

Removal and Disposal

Removal

This section details basic instructions for removal of a Seakeeper 2 from a boat. The overall basic instructions are to reverse the installation instructions:

- Disconnect seawater pump from heat exchanger and power connector on wiring harness.

- Drain heat exchanger of all seawater.

- Disconnect both Seakeeper input power cables.

- Remove all installation fasteners.

- Remove the Seakeeper unit using a spreader bar.

Disposal

DO NOT disassemble the Seakeeper to a greater degree than necessary for removal from the boat. DO NOT dispose of a Seakeeper unit in a landfill. The unit must be shipped back to Seakeeper.