Seakeeper 2 Installation Manual (90488-3); S/N 2-203-0400 to 2-232-1563

Electrical Installation

Electrical Installation Introduction

This section for electrical installation explains how to mount the electrical equipment and how to connect the electrical cables.

Reference Documents & Drawings:

Link to Seakeeper 2 Reference Documents

- 90469 – Seakeeper 2 Hardware Scope of Supply

- 90470 – Seakeeper 2 Cable Block Diagram

- 90438 – 5″ Operator Display Envelope and Mounting Details

- Tb 90191 Seawater Cooling Pump Recommendations

- TB 90478 – Garmin and Seakeeper Compatibility

- TB 90479 – Raymarine and Seakeeper Compatibility

- TB 90480 – Simrad and Seakeeper Compatibility

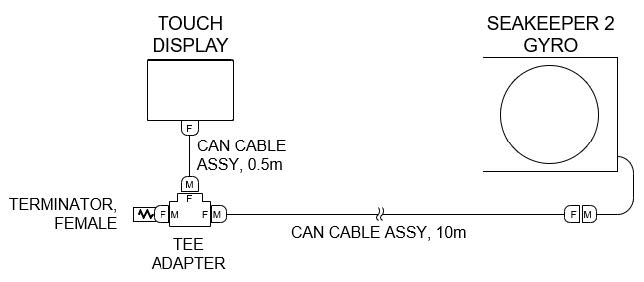

Figure 1 – Electrical Equipment for Seakeeper 2

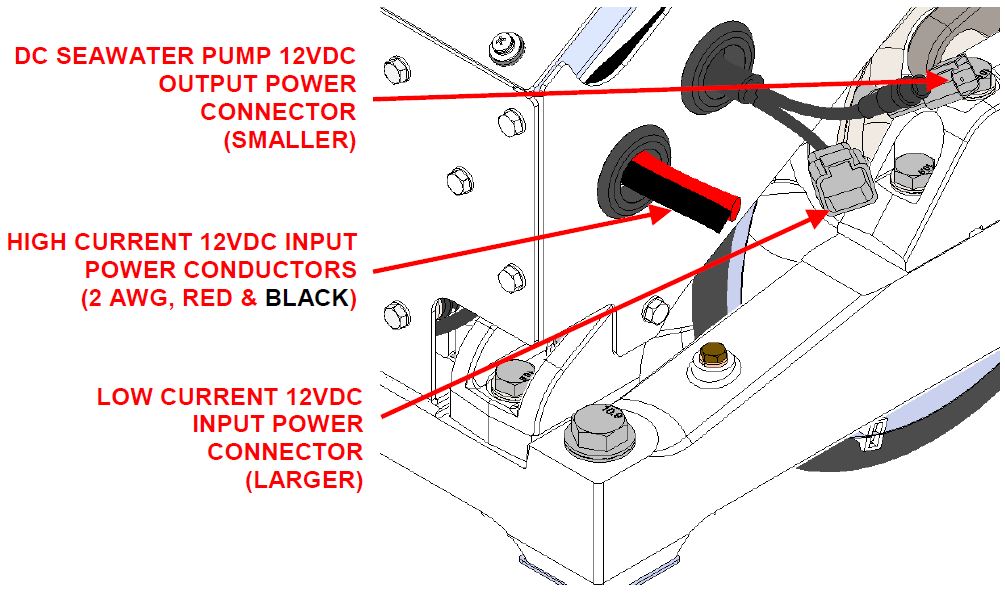

Electrical Equipment Power Connections

High Current 12 V Power Input

High Current 12 VDC Power Source Requirements

| Source | Battery Bank, 12 VDC, Marine, Deep Cycle (AGM battered recommended) |

| Voltage Range | 10 – 15 VDC |

| Continuous Current | 75 A |

| Overcurrent Protection | 100 A (Customer Supplied) |

High Current 12 VDC Power Connection Instructions

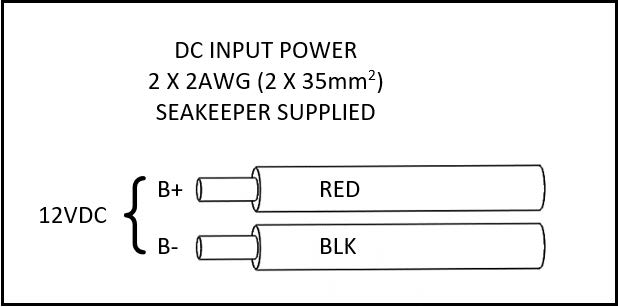

- High Current 2 AWG conductors connect the Seakeeper to the DC source are supplied as length 13ft (4 m). Approximately 3 ft (1 m) is routed inside the Seakeeper frame.

- Conductor length may be increased, but changing from 2 AWG to larger wire size does not allow longer length than 30 ft (9 m) each. The length limit is required to limit the inductance from the high current conductors.

- Use the shortest length and most direct route to the battery bank as possible.

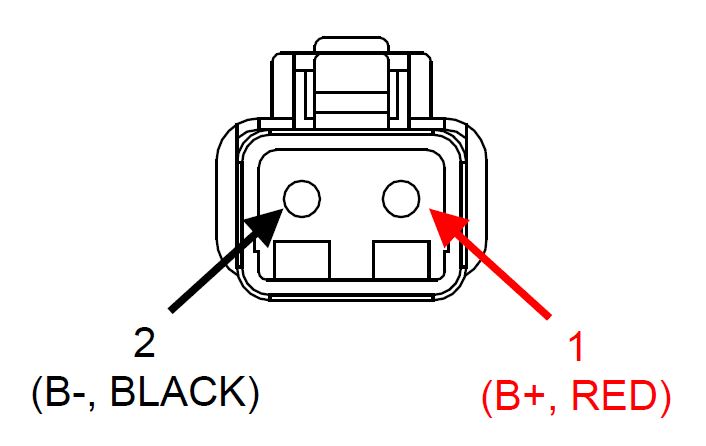

- Bind plus (B+, red) & minus (B-, black) conductors together throughout entire length and do not coil.

- Connect plus conductor (B+, red) through dedicated over-current protection device (customer supplied) and a dedicated isolation switch (customer supplied) then directly to battery plus terminal.

- Connect minus conductor (B-, black) directly to battery minus terminal.

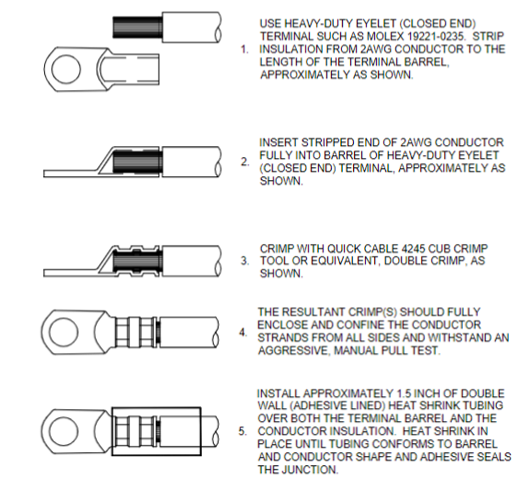

- If the 2 AWG high current 12 V power input conductors are shortened or lengthened, use heavy-duty eyelet (closed end) terminal such as Molex 19221-0235 and follow instructions on Seakeeper Drawing No. 90470 – Seakeeper 2 Cable Block Diagram, sheet 2.

- The bare wire strands should extend fully into the barrel of the heavy-duty eyelet and be crimped in two places if possible then sealed with double-wall heat shrink tubing. Crimp heavy-duty terminals with Quick Cable 4245 Crimp Tool, Molex 19284-0034 Crimp Tool, or equivalent using manufacturer’s instructions.

Low Current 12 V Power Input

Low Current 12 VDC Power Source Requirements

| Source | Battery Bank, 12 VDC, Marine, Deep Cycle |

| Alternate Source | Power Supply / Battery Charger, 12 VDC |

| Voltage Range | 10 – 16 VDC |

| Continuous Current | 9 A |

| Overcurrent Protection | 15 A (Customer Supplied) |

Low Current 12 VDC Power Connection Instructions

Reversing polarity on the DC power input to the Seakeeper can result in damaging the electronics in the control system.

- Install Seakeeper-provided DC Power Input Cable, (P/N 20248) as Cable 7 to battery bank.

- Connect plus conductor (B+, red) through dedicated over-current protection device (customer supplied).

- Connect minus conductor (B-, black) directly to battery minus terminal.

- Before connecting Cable 7 to Seakeeper, check for proper voltage and polarity with a DC multimeter using Figure 5 below.

- Connect Cable 7 to Low Current 12 VDC power input connector on the Seakeeper.

When energizing DC power the first time, if display does not power up immediately then disconnect and inspect connector polarity.

DC Seawater Pump 12 V Power Output

DC Seawater Pump 12 VDC Power Source Specifications

| Source | 12 VDC from the Seakeeper |

| Voltage Range | 10 – 15 VDC |

| Continuous Current | On-demand, typically ~10 A |

| Overcurrent Protection | Per pump specification, max 15 A |

DC Seawater Pump 12 VDC Power Input Connection Instructions

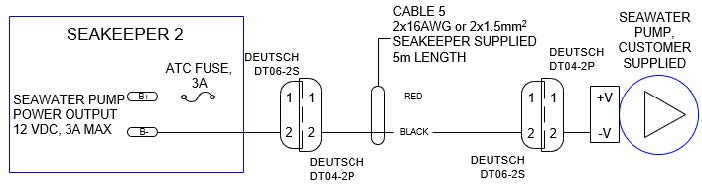

- Located the Seawater Pump Power Input Cable (P/N 30327) for Seakeeper 2 “SW Pump DC In” connection on Seakeeper 2 wire harness (as shown in Drawing No. 90470).

- Connect the 16AWG plus conductor (red) through dedicated overcurrent protection device (customer-supplied), maximum of 15A, to dedicated battery isolation switch.

- The High Current, 2AWG B+ conductor (red), is capable of carrying the current for both the High Current, Low Current, and Seawater Pump from the 12VDC power supply to the dedicated battery isolation switch.

- Connect the 16 AWG minus conductor (black) directly to battery minus terminal or DC main negative bus bar.

- Before connecting the SW Pump Power Input Cable to the Seakeeper 2, check for proper voltage and polarity with a DC multimeter using Figure 6 below.

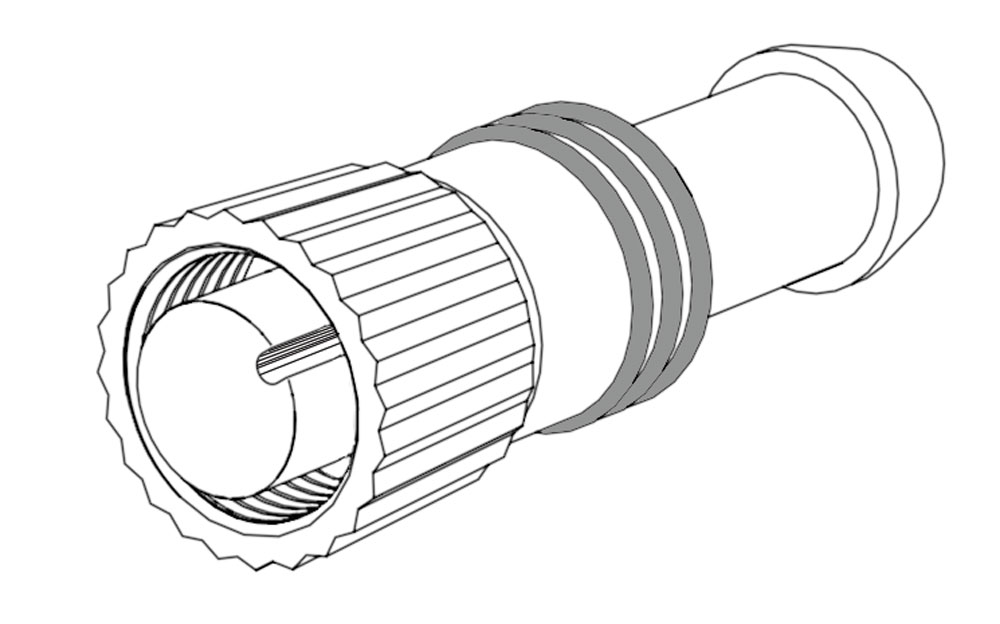

- Connect SW Pump Power Input Cable to Seawater Pump 12 VDC In connector on the Seakeeper, DEUTSCH DT04-2P connector.

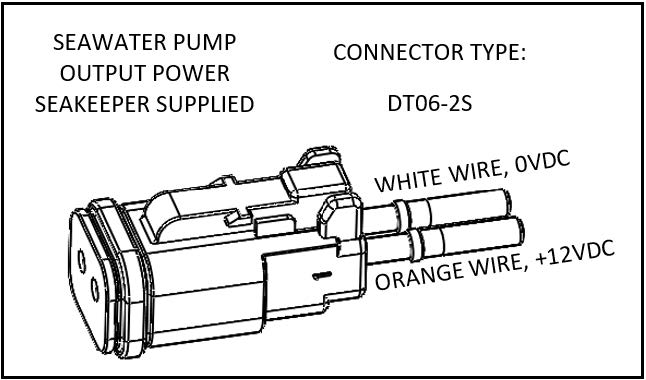

Seawater Pump 12 VDC Power Output Connection Instructions

- Locate the Seawater Pump Power Output Cable (P/N 20334) for “SW Pump 12VDC Out” connection on Seakeeper 2 wire harness (as shown in Drawing No. 90470).

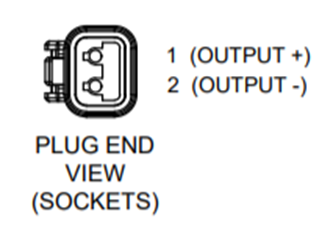

- Pumps rated at 12 VDC, 15 amps maximum, customer-supplied, must be configured with a Deutsch DT series, 2-pin receptacle to mate with the connector as shown in Figure 7.

- TE Connectivity (Deutsch) DT04-2P Receptacle, 2-Way, for Male Pins (qty 1)

- TE Connectivity (Deutsch) 0460-202-1631 Pin, Solid, Gold-plated, Size 16, 16-20 AWG (qty 2)

- TE Connectivity (Deutsch) W2P Wedgelock for 2-Way DT Receptacle (qty 1)

- The Seawater Pump Power Output Cable must be routed and installed in the vessel from the Seakeeper 2 “SW Pump 12VDC Out” Deutsch connector plug (pins end) to the DC seawater pump cable Deutsch connector (socket end).

- Connect Seawater Pump Power Output Cable (socket end) to the customer-supplied receptacle end (pins end). The recommended wiring arrangement is shown in Figure 8

- Seakeeper DC Seawater Pump Assembly (P/N 30331), which is prewired for Cable 5, is available as an option with the Seakeeper 2.

Electrical Equipment Ground Connections

Seakeeper to Vessel Ground Connection Instructions

- Connect the Seakeeper foundation ground stud, shown in the following Figure to vessel ground.

- Install Ground Wire (4 AWG or 25 mm2, Customer Supplied) from the M6 brass ground stud on the rear brace to a suitable vessel ground.

- NOTE: ONLY USE THIS LOCATION FOR GROUNDING THE SEAKEEPER TO THE VESSEL GROUND.

Operator Station

This section explains the connection between the Operator Station equipment and the Seakeeper.

Reference Documents & Drawings

- 90470 – Seakeeper 2 Cable Block Diagram

Determine Location of Operator Station

- The desired location of the Operator Station must be determined with respect to the vessel arrangement.

- The operator display should be located on the bridge console.

- Figure 11 below shows the CAN bus communications link for the Operator Station. The Terminator goes on the far end of the Tee Adapter from the Seakeeper.

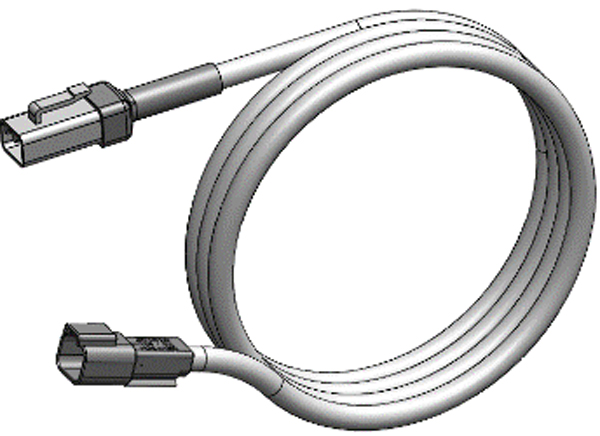

Route CAN Communications Cable

- The CAN Cable Assembly (P/N 30295, Cable 3) is a 10 m shielded cable and the largest connector is a molded plug with maximum outer diameter of .58 in. (14.8 mm).

- Cable 3 must be routed and installed in the vessel from the Seakeeper (female end) to the Tee Adapter (male end) at the Operator Station.

Install Operator Station Equipment

- The Operator Station equipment is installed at the selected location using instructions found in Section: Electrical Equipment Mounting.

Connect Operator Station Equipment

- The Operator Station equipment is connected in accordance with Drawing No. 90470 – Seakeeper 2 Cable Block Diagram.

Electrical Equipment Mounting

Precautions: Each item of electrical equipment has specific mounting instructions. These instructions

should be followed to ensure proper function of the Seakeeper.

Do NOT move Seakeeper mounted components from their

locations or incorrect Seakeeper operation will result.

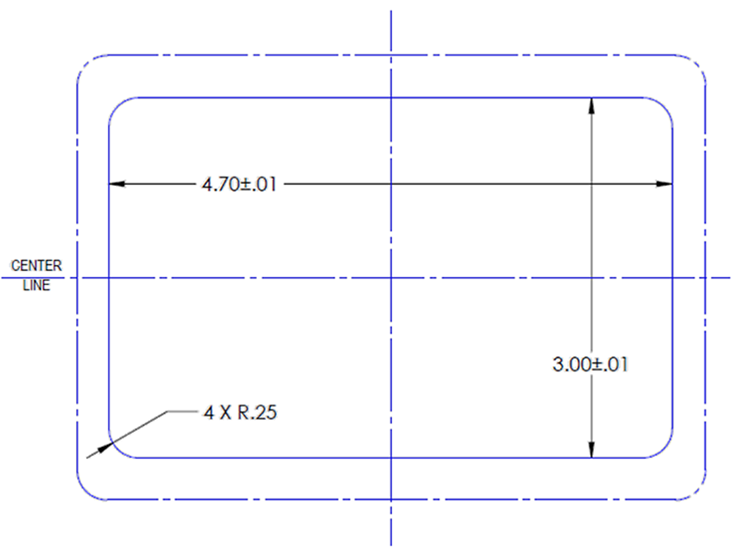

- Touch Display Mounting Instructions, Surface Mount

- Console space required: Approx. 5.24 W x 3.70 H in. (133 x 94 mm)

- Mounting Instructions, Surface Mount: See Drawing No. 90438 – 5″ Operator Display Envelope and Mounting Details, for details.

- CAN Communications Tee Adapter and Terminator Mounting Instructions

- Console space required, Rear: Approx. 4 W x 3 H in. (102 x 76 mm), rear

- Mounting Instructions: Rear mount on vessel console panel, within 2 ft (0.6 m) of Display.

- Hardware required: One mounting screw for .197 in. (5 mm) diameter mounting hole on Tee Adapter.

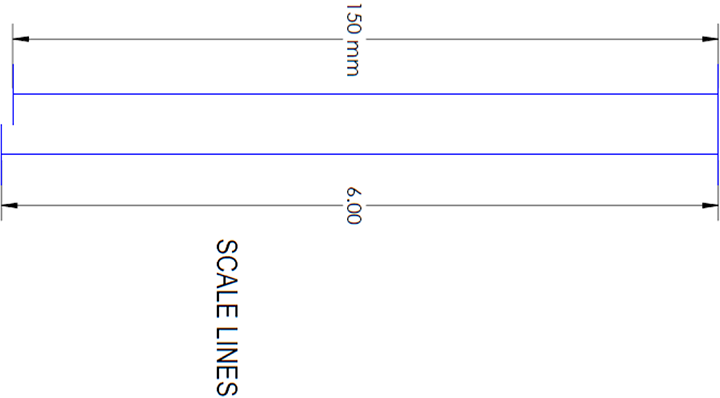

Display Installation Template

The following template is for mounting; before using this template, measure to ensure that the shown size is actual.