Seakeeper 1 Operation Manual (90520-1)

Start Up Instructions

Power On

- Energize Seakeeper 1 Battery Isolation Switch.

- Energize Seakeeper 1 High Current DC Power Supply (12 VDC, 80 A) at customer-supplied circuit breaker.

- Energize 12 VDC seawater pump power supply at the customer-supplied circuit breaker (unless a fuse is supplied as overcurrent protection).

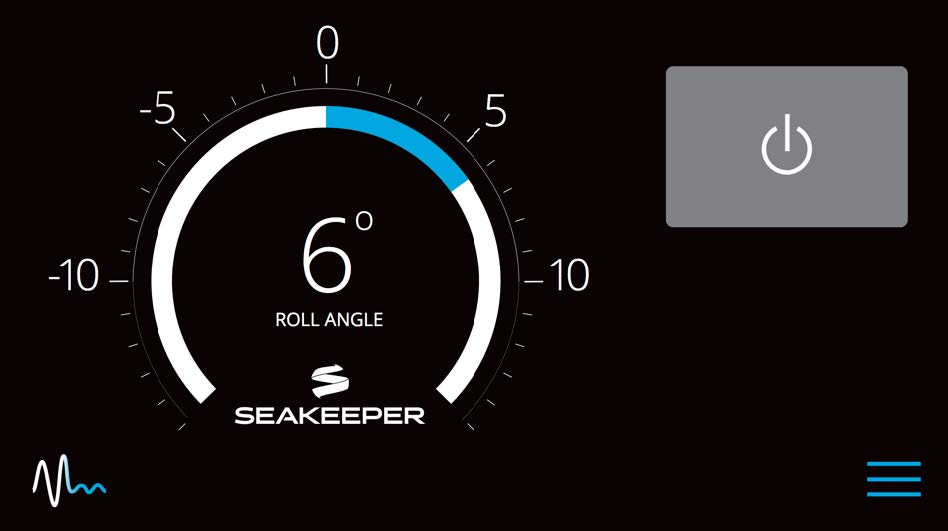

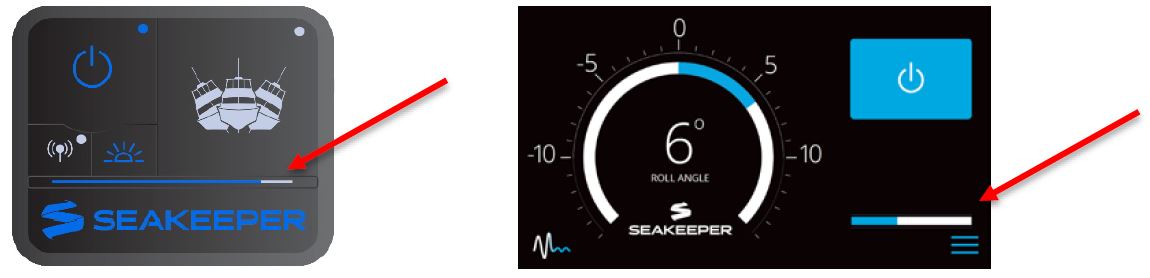

- When the high DC power is turned on, the ConnectBox and Seakeeper 5” Touch Display and/or MFD application will initialize as seen below. The Seakeeper 1 can be powered on and controlled by either the Seakeeper Application or the ConnectBox.

- With system energized, check the Seakeeper display for any ALARMS. If there are any ALARMS present, they must be addressed to proceed.

- To turn the Seakeeper on, press the POWER button; the button will turn blue. The progress bar will appear and indicate how soon the Seakeeper will be available for stabilization. The progress bar indicates the speed of the flywheel as it accelerates to its rated operating RPM.

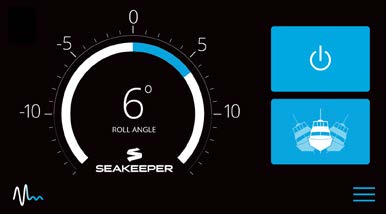

- When the Seakeeper is initialized and up to Stabilization RPM the STABILIZE button will appear on the application, or if using the ConnectBox, the STABILIZE button will illuminate blue and pulsate. At this point, the Seakeeper is available for stabilization by pressing the STABILIZE button.

- The progress bar indicating flywheel spool-up will disappear from the display screen once the STABILIZE button is pressed (turns blue) and the ConnectBox will fully illuminate. At this point, the Seakeeper has reached its rated operating RPM and maximum stabilization is available. If the STABILZE button has not been pressed (button is grey), pressing the button will turn it blue and stabilization will be provided. The seawater pump will cycle on and off based on the operating temperature of the Seakeeper 1.

Stabilization

To stabilize the vessel after the Seakeeper is On and the flywheel is above the minimum stabilization RPM:

Press the STABILIZE button. The button will turn blue indicating that the Seakeeper is stabilizing the roll motion.

If it is necessary to shut off power to the flywheel motor and slow the flywheel for any reason, press Seakeeper On/Off button; the button will turn grey and the STABILIZE button will disappear, indicating the command has been accepted. It takes approximately 2+ hours for the speed to slow down to 0 RPM.

If it is necessary to stop Seakeeper motion for any reason press the STABILIZE button. The STABILIZE button will turn grey indicating that the Seakeeper is locked. Never attempt to work on the Seakeeper until the flywheel has stopped spinning. If the brake system has automatically locked the Seakeeper due to an alarm or failure, no attempt should be made to bypass the alarm or automatic lock.

Normal Shut Down

The Seakeeper should be shut down when stabilization is no longer required. This maximizes the longevity of the Seakeeper 1.

- Press the Seakeeper POWER button. The POWER button will turn grey. The Seakeeper will discontinue stabilization and the flywheel will start coasting.

- Once the vessel is secured in the slip, switch the high current (80 A circuit breaker) and low current (circuit breaker rated per seawater pump) DC power to the Seakeeper off. The flywheel will continue to spool down to 0 RPM. This can take 2+ hours from full speed. When the flywheel has stopped spinning, 0 RPM will appear on the service screen.

The Seakeeper should be stopped when stabilization is no longer required. Once the vessel is secured in the slip, the high and low current DC power to the Seakeeper should be switched to the Off position. The Seakeeper will continue to spool down to 0 RPM. No cooling is required during this time. Note Seakeeper will take 2+ hours to coast down to 0 RPM from full speed.

Note: The seawater pump may run for up to 5 minutes after the Seakeeper is switched off and is coasting (with low current DC power applied).

Power Failures, Alarms, and Troubleshooting

Power Failures, Alarms, and Troubleshooting Introduction

The Seakeeper 1 has safety features, such as alarms and warnings, that pop-up on the Seakeeper Application and are signaled on the ConnectBox to protect the Seakeeper as well as the vessel. The brake can be locked from the Application, ConnectBox or by shutting off DC power at the supply breakers, preventing the Seakeeper from precessing.

Power Failures

In the event of a power failure, the brake automatically locks the Seakeeper so it cannot generate anti-rolling torque loads.

When a power failure occurs, it is important to identify the two sources of power to the Seakeeper 1:

- High current 12 VDC in, powers the control electronics and motor drive.

- SW Pump 12 VDC in, powers the seawater cooling pump.

These are supplied on Conductors 1 and 2 and Cable 7 which are shown on Drawing No. 90511 – Seakeeper 1 Cable Block Diagram.

The Motor Connections should not be touched when the Seakeeper is powered on or the motor is running. This voltage hazard exists even if the flywheel is coasting down and the supply voltage has been shut off. The flywheel must be at 0 RPM and DC input power disconnected for at least 10 minutes prior to any service work on the Seakeeper.

12 VDC High Current Failure

If the 12 VDC high current is disconnected during operation, the Seakeeper Application will go blank, ConnectBox lights will power down, flywheel speed will decrease, and the Seakeeper 1 will lock to prevent precession (no stabilization).

- Verify the boat’s overcurrent protection supplying +12 VDC high current has not tripped nor blown.

- When +12 VDC high current is restored, the Seakeeper App will power up on the display (MFD or 5” Touch Display), the start-up screen will appear, and then the Home Screen will appear. The ConnectBox will illuminate.

- Press POWER button

. The progress bar will appear and indicate flywheel speed. When the flywheel is at minimum operating speed, the STABILIZE button will appear so stabilization can be turned on. This may take up to 15 minutes, depending on the speed of the flywheel when the +12 VDC high current is turned back on.

. The progress bar will appear and indicate flywheel speed. When the flywheel is at minimum operating speed, the STABILIZE button will appear so stabilization can be turned on. This may take up to 15 minutes, depending on the speed of the flywheel when the +12 VDC high current is turned back on.

Alarms

Sensors, alarms, and shutdowns are provided to allow unattended operation. Sensors measure drive temperatures, gimbal angle, brake pressure, and vessel motion. The Seakeeper controller sends sensor values and alarm information to the display and locks the brake and shuts down the motor drive in the event of an alarm condition. Seakeeper operating history during faults or alarms is recorded in the controller’s memory for subsequent recall if service is needed. Seakeeper and Seakeeper Dealers may access the Seakeeper’s software to gather run hours, bearing loading, and hull slamming information.

NOTE: The ConnectBox indicates the presence of an alarm only. The Seakeeper Application must be used on either the Seakeeper 5” Touch Display or the MFD to identify and address the alarm.

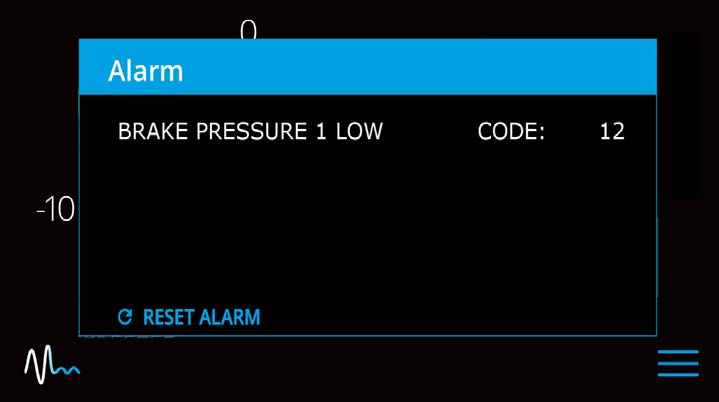

The alarm will not clear until the operator presses the Reset Alarm button and the alarm condition is no longer present. The operator can then press the POWER button again to resume Seakeeper operation.

- A view of a typical Alarm screen.

- To reset the alarm, press the RESET ALARM button:

Alarm History

The Alarm History page on the Seakeeper Application shows the recent alarms and warnings. Alarms trigger a pop-up message to be displayed on the Seakeeper App and cause the ConnectBox power button to pulse red as alarms affect Seakeeper operation. Warnings will be listed in the alarm history but do not affect Seakeeper operation. The alarms and warning history are in chronological order starting with the most recent. Press the MENU button ![]() to show the page options and then the ALARM button

to show the page options and then the ALARM button ![]() to show alarm history.

to show alarm history.

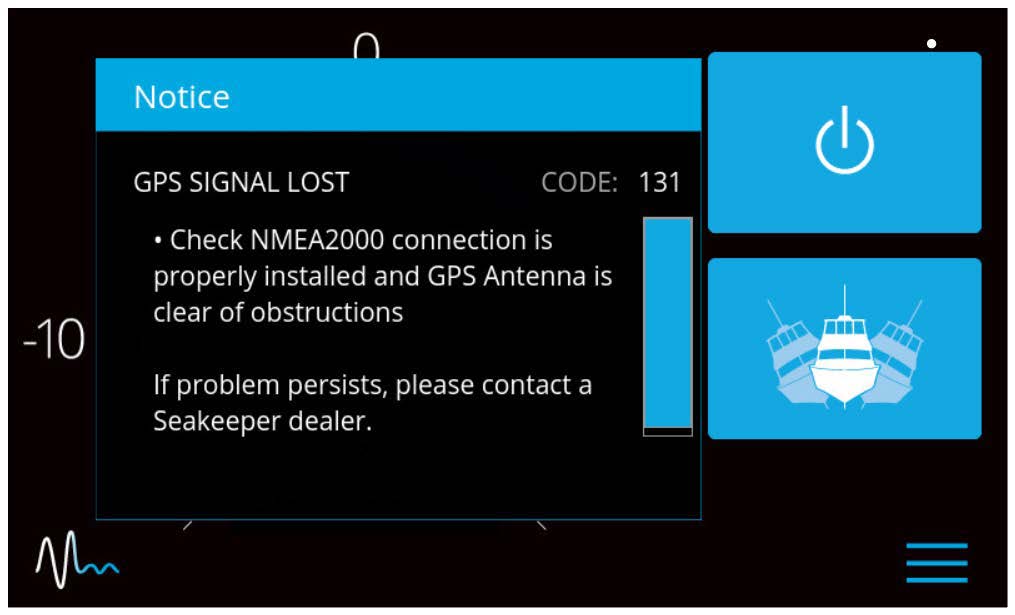

If a GPS signal is lost, a warning message will appear in the Alarm History and a message will appear on the Home Screen, as seen below. The Seakeeper will not spool down, however the precession rate and angle of the sphere will be reduced until GPS signal returns.

Maintenance

Maintenance Introduction

Reference Documents:

Link to Technical Library Documents

Due to remote start capabilities of MFDs, ENSURE power removed from Seakeeper and flywheel at zero RPM at display/MFD app before removing covers.

Hydraulic Hand Pump Kit is required for servicing the brake. Pressure should NOT be relieved unless this tool is available.

Maintenance

Seakeeper recommends a regular inspection interval and scheduled maintenance to keep the Seakeeper 1 running trouble-free.

If the Seakeeper is installed in a wet space, efforts should be made to keep the Seakeeper free of salt residue from either condensation or direct exposure to salt spray. If exposed, a regular wipe down with mild soap and water with a rinse will help limit corrosion and keep the Seakeeper assembly in good cosmetic condition. Refer to How to Care for Your Seakeeper article for details.

If any components of the Seakeeper or its sub-systems will be exposed to environmental temperatures where winterization is necessary for storage, reference How Do I Winterize My Seakeeper? article for details.

The Seakeeper comes standard with sealant and thread locker on applicable fasteners. When reinstalling all fasteners, use thread locker (Loctite 243 or equivalent) and sealant unless otherwise specified.

Recommended Scheduled Maintenance Table

This page contains the scheduled maintenance table organized by systems: Mechanical, Hydraulic, Cooling, and Electrical. Recommended scheduled maintenance is not covered under warranty.

- The Recommended Scheduled Maintenance should be performed by a SEAKEEPER trained factory technician or trained technician within the Seakeeper Dealer network. Find a local Dealer on our website at www.seakeeper.com/find-us/.

- A Seakeeper technician or Dealer is required to perform a brake service and to replace brake bushings or other brake components. This requires a complete flush, bleed, purge and pressurization of the closed hydraulic system.

- Scheduled Maintenance and the replacement of ‘wear’ items are not covered by the www.seakeeper.com/extended-warranty/recreation-warranty/.

| System / Component | Task | Interval | Parts / Special Tools |

|---|---|---|---|

| Mechanical / Corrosion | Inspect unit for severely corroded areas and clean and touch up with paint. See Service Bulletin 90026. | 12 Months or 1000 Hours | Awlgrip Paint P/N’s: Primer: S9001 Primer Converter: S3001 Top Coat, Snow White: F8063 Top Coat Converter: G3010 |

| Mechanical / Safety Latch | Seakeeper or Dealer inspect safety latch for wear, alarm will indicate when LIC exceeds 90,000 instances, found on Info Page of the Seakeeper Application. | Inspect at 12 Months or 1000 hours. Replace at 2000 hours or when LIC exceeds 90,000. | |

| Hydraulic / Brake Actuator | Inspect for leaks. | 12 Months or 1000 Hours | |

| Cooling / Hoses | Check for cracks or chafing. If damaged, replace hose. Fill cooling system and purge air. | 12 Months or 1000 Hours | Anti-freeze – 50/50 Ethylene Glycol mix. |

| Cooling / Seawater side | Inspect heat exchanger for signs of leaks. | 3 Months or 150 Hours | |

| Cooling / Seawater side | Fill with environmentally safe, marine anti-freeze during winter or periods of in-operation. | Winter | |

| Electrical / Connectors | Inspect all connectors for corrosion, replace if necessary. | 12 Months or 1000 Hours | |

| Electrical / Grounds | Inspect all ground points for corrosion, clean as necessary, and treat with corrosion inhibitor. | 12 Months or 1000 Hours | |

| Electrical / Cables | Check all cables and wire harness branches for cracks or chafing. Take special attention to gimbal shaft areas. | 12 Months or 1000 Hours | |

| Electrical / Motor Power | Check integrity of motor power and motor ground conductors. | 12 Months or 1000 Hours | |

| Hydraulic / Brake Bushings | Replace brake bushings | Inspect at 12 Months or 1000 Hours – Replace as needed or at 2000 Hours | |

| Cooling / System | Cooling system flush | 12 Months or 1000 Hours | Fill reservoir, antifreeze – 50/50 Ethylene Glycol mix |

Warranty, Limit of Liability, Property Rights

Warranty

The complete Seakeeper warranty details may be found on the Seakeeper website www.seakeeper.com.

Seakeeper Recreational Limited Warranty Policy

Seakeeper warrants that the Goods sold hereunder are free from defects in material and workmanship. This warranty starts from the earlier of the purchase date by the first end-user/retail purchaser or the in-service date, and the warranty period is for the shorter of the following periods:

- 24 months (2 years) from date the Product is put into service, which shall conclusively be presumed to be the date of sale of a vessel on which the Product is installed, to a retail customer or date put into service on an existing vessel (refit), or

- 2000 (two thousand) operating SEA hours, subject to verification and confirmation by SEAKEEPER, INC.

All Seakeeper Models

This warranty does not cover normal wear of the following components or the costs associated with maintenance, repair or replacement:

- Surface Corrosion (Cosmetic) on any component due to exposure

- Heat Exchanger

- Brake Bushings

- Isolation Bushings

- Normal preventive and scheduled maintenance and component inspections/replacements as specified in the Seakeeper, Inc., Operation Manuals and any other Maintenance Schedule documentation.

This express warranty is in lieu of and excludes: ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, BY OPERATION OF LAW OR OTHERWISE INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE (WHETHER KNOWN TO SELLER OR NOT), AND ALL OTHER SUCH WARRANTIES ARE HEREBY EXPRESSLY DISCLAIMED BY SELLER AND WAIVED BY CUSTOMER/END USER. SEAKEEPER, INC. SHALL IN NO EVENT BE LIABLE TO ANY SPECIAL, DIRECT, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES FOR BREACH OF ANY WARRANTY OR OTHER OBLIGATION ARISING OUT OF THE SALE OF THE PRODUCTS, OR FROM THE USE OF THE PRODUCTS OR ANY INABILITY TO USE THE PRODUCTS.

Written notice of claimed defects shall have been given to Seakeeper within the Warranty Period, and within thirty (30) days from the date any such defect is first discovered. The Goods or parts claimed to be defective must be returned to Seakeeper, accompanied by a Return Authorization (RA) issued by Seakeeper‘s facility responsible for supplying Goods, with transportation prepaid by Buyer/User, with written specifications of the claimed defect.

If a warranty claim is valid, SEAKEEPER, INC. will repair or replace the Product, or part of the Product, proven to be defective, at its sole discretion, in a timeframe provided by SEAKEEPER, INC., on a reasonable best effort basis.

Under no circumstances shall Seakeeper be liable for removal of Seakeeper‘s Goods from Buyer’s/User’s equipment or re-installation into Buyer’s/User’s equipment. No person including any agent, distributor, or representative of Seakeeper is authorized to make any representation or warranty on behalf of Seakeeper concerning any Goods manufactured by Seakeeper

Warranty Activation

A Warranty Registration must be fully completed and sent to Seakeeper, Inc., for review, approval and registration upon delivery of the vessel to the first retail customer. Warranty registration and expiration date confirmation can be achieved by providing Seakeeper, Inc., a copy of the original bill of sale, purchase agreement, Owner’s name, address and Seakeeper Stabilizer Serial Number along with current Run / Sea hours to Seakeeper’s warranty registration department within thirty (30) days of purchase. For removal of doubt, it is clarified that the activation date shall in no event affect the warranty period set forth herein.

“Owner” is defined as the first retail customer (purchaser), or subsequent customer (by transfer), of the Seakeeper Product as identified in Seakeeper warranty registration(s).

Limitation of Liability

NOTWITHSTANDING ANYTHING TO THE CONTRARY, SEAKEEPER SHALL NOT BE LIABLE FOR ANY SPECIAL, INCIDENTAL, INDIRECT OR CONSEQUENTIAL DAMAGES INCLUDING BUT NOT LIMITED TO LOST PROFITS ARISING OUT OF THE PERFORMANCE, DELAYED PERFORMANCE OR BREACH OF PERFORMANCE OF THIS ORDER REGARDLESS WHETHER SUCH LIABILITY BE CLAIMED IN CONTRACT, EQUITY, TORT OR OTHERWISE. SEAKEEPER’S OBLIGATION IS LIMITED SOLELY TO REPAIRING OR REPLACING (AT ITS OPTION AND AS SET FORTH IN SECTION 5), AT ITS APPROVED REPAIR FACILITY, ANY GOODS OR PARTS WHICH PROVE TO SEAKEEPER’S SATISFACTION TO BE DEFECTIVE AS A RESULT OF DEFECTIVE MATERIALS OR WORKMANSHIP, IN ACCORDANCE WITH SEAKEEPER’S STATED WARRANTY. IN NO EVENT SHALL SEAKEEPER’S LIABILITY EXCEED THE TOTAL PURCHASE PRICE SET FORTH IN THIS ORDER.

Property Rights

Except where otherwise expressly agreed, all patterns, tools, jigs and fixtures, drawings, designs, software and other materials and data developed, fabricated by Seakeeper shall be and shall remain Seakeeper‘s property. Except as specifically provided for in the order, Buyer shall have no right in any technical data, Intellectual Property Rights, and computer software associated with the order. Buyer shall not use or permit the use of the Goods that in any way could result in the disclosure of Seakeeper‘s proprietary information.

Seakeeper Specifications

Specifications & Summary

| Rated RPM | 9,750 RPM |

| Angular Momentum at Rated RPM | 1,000 N-m-s |

| Anti-Rolling Torque at Rated RPM | 2,620 N-m |

| Spool-up Time to Rated RPM (9750 RPM) | 30 minutes (9,750 RPM) |

| Spool-up Time to Stabilization RPM | 15 minutes (7,650 RPM) |

| Spool-up Power DC Motor | 600 Watts Max |

| Operating Power DC (Sea state dependent) | 300-600 Watts |

| Voltage DC Input | 12 VDC @ 55 Amps |

| Seawater Supply to Heat Exchanger | 4 GPM (15 LPM) maximum 2 GPM (8 LPM) minimum |

| Ambient Air Temperature | 32˚ – 140˚F (0 – 60˚C) |

| Weight | 365 lbs (165 kg) |

| Envelope Dimensions | 22.9 L x 23.6 W x 15.7 H (inches) 0.582 L x 0.598 W x 0.398 H (meters) |

| Noise Output | At full operating RPM, steady state noise measured in the factory at a 1-meter distance measures 62-64 dBC (sound levels may be higher during spool-up). |