Seakeeper 9 Installation Manual (90222-11); S/N 9-233-4900 to Current

2.5.4 Seakeeper Saddle Preparation

- Ensure that screws fastening saddles to the installation fixture are tight (Figure 14).

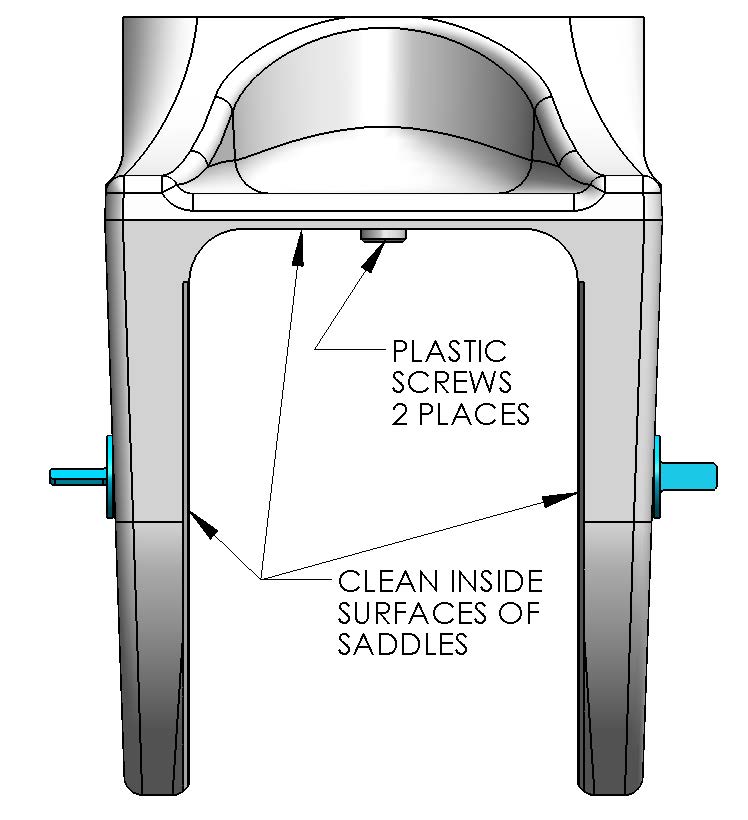

- Check that each saddle contains 2 plastic screws which will ensure an adhesive gap of .080 in. (2 mm) on top surface of hull as shown in Figure 16. Do not remove these screws.

- Thoroughly sand all saddle inside surfaces with 80 grit sandpaper in cross-hatch pattern. (IMPORTANT – BOND STRENGTH MAY BE REDUCED IF THIS STEP IS SKIPPED.)

- Thoroughly clean with alcohol or acetone the inside surfaces of Seakeeper foundation saddles to remove any contaminates as shown in Figure 16. Use new paper towels for cleaning, not shop rags.

- If using Plexus MA590 adhesive, apply Plexus PC-120 surface conditioner to inside surfaces of Seakeeper foundation saddles in accordance with manufacturer instructions. These instructions are located at the end of this section. If using an alternate adhesive, check with manufacturer if any surface conditioner/etch is required for the aluminum saddles.