Seakeeper 4.5 Operation Manual (90763-1)

3.2 Operating Instructions

3.2.1 Start Up

3.3.2 Stabilization

3.3.3 Normal Shutdown

4.0 Power Failures and alarms

4.1 Power Failures and Alarms Introduction

4.2 Power Failures

4.3 Alarms

5.0 Maintenance

5.1 Maintenance Introduction

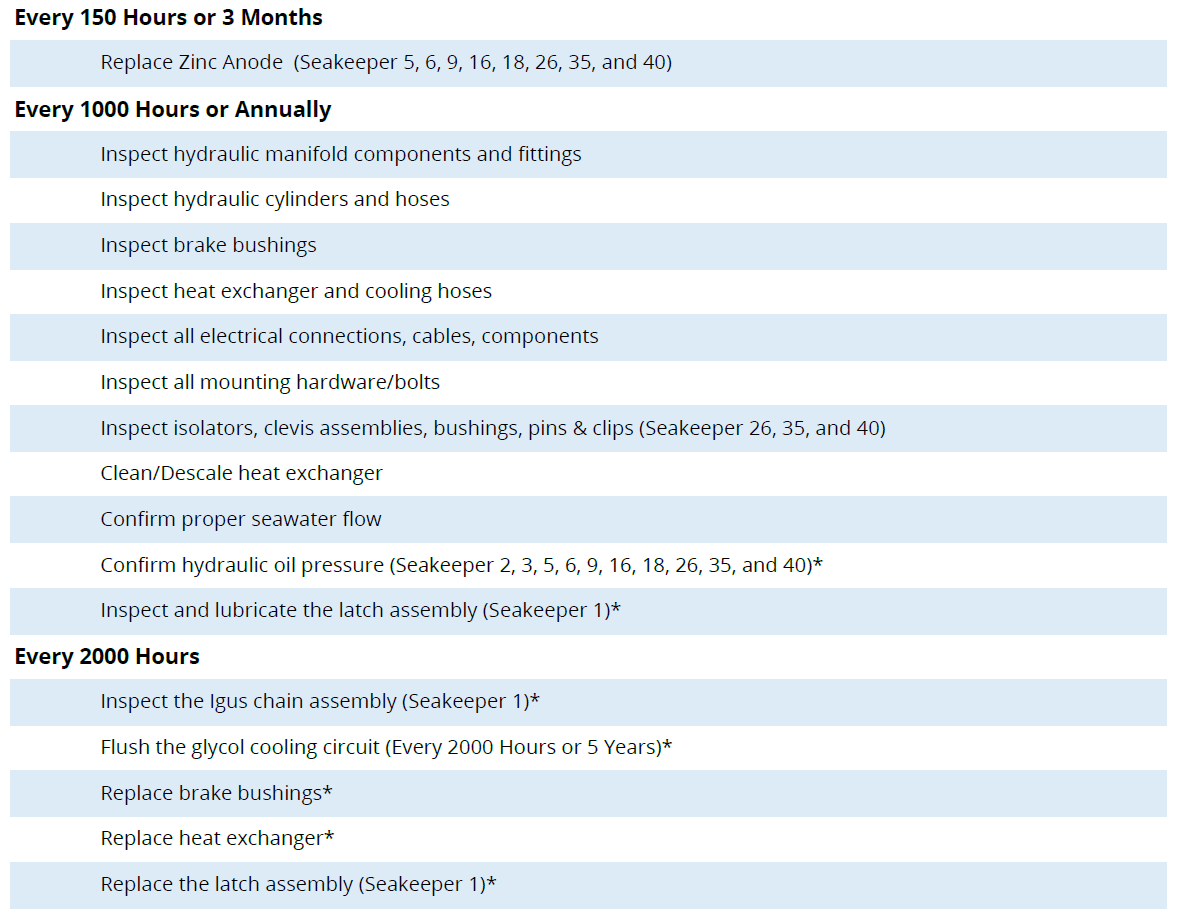

5.2 Scheduled Maintenance Table

The following contains the scheduled maintenance table organized by RUN hours. Scheduled maintenance is not covered under warranty.

*These tasks must be performed by a certified Seakeeper Dealer.

Find a local Dealer at www.seakeeper.com/find-us

Perform the Recommended Maintenance after the indicated number of Running [RUN] hours or Years since last maintenance, whichever occurs first.

Seakeepers are designed for use in a marine environment and to withstand occasional water spray or splash. Prolonged exposure to seawater, however, can cause premature wear and damage to the unit; therefore, it is important to apply a gentle fresh water rinse following exposure to seawater.

The service intervals are based on ‘average’ use, including operating in various Sea conditions, such as zero or low-speed usage in/around marinas and anchorages vs. different speeds while underway in light or heavy sea conditions. If the customer’s normal operating conditions include extended SEA operation, more frequent service should be considered.

6.0 Warranty and Limit of Liability

6.1 Warranty

The complete Seakeeper warranty details may be found on the Seakeeper website www.seakeeper.com.

Register your Seakeeper at the Seakeeper Warranty Registration page.

Seakeeper Standard Models

This warranty starts upon the installation of the Product, and the warranty period is for the shorter of the following periods:

- Twenty-four (24) months from purchase date of a vessel on which the Product is installed;

- Twenty-four (24) months from date the Product is installed on an existing vessel (refit); or

- Two thousand (2000) operating SEA hours, subject to verification and confirmation by SEAKEEPER.

Exclusions

Any installation, repair or any handling of the Product shall be done only by an authorized person trained and explicitly authorized in writing by SEAKEEPER.

This warranty shall be void and not apply to or resulting from:

- ANY UNAUTHORIZED MODIFICATION OF THE PRODUCTS AS SHIPPED WILL RESULT IN VOIDING THIS WARRANTY.

- An application or installation method not approved by Seller, including improper or inadequate site preparation, faulty installation, handling during maintenance or otherwise, if any, by the Customer, as well as to defects attributable to loading/shipment/delivery of the Product or any other defect or damage not attributable to SEAKEEPER.

- Defects resulting from Customer’s or any third-party interface of equipment, hardware or software if installed, connected, or loaded into and/or onto the Product.

- Misuse, operator error or fault caused by the failure of an external unit (i.e., Sea Water pump, Ships power supply).

- Any negligent or willful misconduct.

- Excessive exposure to water (salt or fresh) including submersion (partial or full).

- Acts of Nature such as, but not limited to, fire, flood, wind, and lightning.

- Improper use or operation of the vessel.

- Failure of the Customer to strictly comply with any of the following requirements:

- Operation and Maintenance according to the guidelines and recommendations specified in the SEAKEEPER Operation Manual.

- Proof of such compliance shall be provided upon request.

- Operation and Maintenance according to the guidelines and recommendations specified in the SEAKEEPER Operation Manual.

Warranty Activation

A Warranty Registration must be fully completed and sent to SEAKEEPER for review, approval and registration upon delivery of the vessel to the first retail Customer. Warranty registration and expiration date confirmation can be achieved by providing SEAKEEPER, a copy of the original bill of sale, purchase agreement, Customer’s name, address and SEAKEEPER Product Serial Number along with current RUN / SEA hours to SEAKEEPER’s warranty registration department within thirty (30) days of purchase.

For removal of doubt, it is clarified that the activation date shall in no event affect the warranty period set forth herein.

6.2 Limitation of Liability

NOTWITHSTANDING ANYTHING CONTAINED HEREIN TO THE CONTRARY, SEAKEEPER, INC., SHALL NOT BE LIABLE FOR ANY SPECIAL, PUNITIVE, INCIDENTAL, INDIRECT OR CONSEQUENTIAL DAMAGES INCLUDING, BUT NOT LIMITED TO, LOST PROFITS, ARISING OUT OF THE PERFORMANCE, DELAYED PERFORMANCE OR BREACH OF PERFORMANCE OF THIS ORDER REGARDLESS OF WHETHER SUCH LIABILITY IS CLAIMED IN CONTRACT, EQUITY, TORT OR OTHERWISE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. SEAKEEPER’S OBLIGATION IS LIMITED SOLELY TO REPAIRING OR REPLACING (AT ITS OPTION AND ONLY AS SET FORTH HEREIN), AT ITS APPROVED REPAIR FACILITY, ANY GOODS OR PARTS WHICH PROVE TO SEAKEEPER’S SATISFACTION TO BE DEFECTIVE AS A RESULT OF DEFECTIVE MATERIALS OR WORKMANSHIP, IN ACCORDANCE WITH SEAKEEPER, INC.’S STATED WARRANTY. IN NO EVENT SHALL SEAKEEPER’S CUMULATIVE LIABILITY EXCEED THE TOTAL PURCHASE PRICE SETFORTH IN THIS ORDER. CUSTOMER HOLDS HARMLESS SEAKEEPER AND INDEMNIFIES SEAKEEPER FOR ANY ACT OR OMISSION TO ACT THAT VOIDS THE LIMITED WARRANTY OR OTHERWISE BREACHES CUSTOMER’S OBLIGATIONS PURSUANT TO THE TERMS AND CONDITIONS OF SALE.

The terms and conditions of this warranty are the entire agreement between the Parties relating to the warranty obligations of SEAKEEPER to the Products. There are no other express or implied terms or conditions of this warranty.

7.0 Seakeeper Specifications

| Specification | Seakeeper 4.5 |

|---|---|

| Rated RPM | 9,300 RPM |

| Angular Momentum at Rated RPM | 4,500 N-m-s |

| Anti-Rolling Torque at Rated RPM | 11,780 N-m |

| Spool-up Time to Rated Speed | 35 minutes (9,300 RPM) |

| Spool-up Time to Stabilization | 19 minutes (6,975 RPM) |

| Spool-up Power DC Motor | 1,950 Watts Max |

| Operating Power DC (Sea state dependent) | 950 – 1,600 Watts |

| Voltage AC Input | 110 – 120 VAC @ 30 Amps, OR 208 – 230 VAC @ 20 amps (50/60/Hz, Single Phase) |

| Control Power Input | 12 VDC @ 15 Amps Max |

| Seawater Power Input | 12 VDC @ 15 Amps Max |

| Seawater Supply to Heat Exchanger | 2.5 GPM (9.5 LPM) minimum 4 GPM (15.2 LPM) maximum |

| Ambient Air Temperature | 32˚ – 140˚F (0 – 60˚C) |

| Weight | 736 lbs (334 kg) |

| Envelope Dimensions | 26.56 L x 28.05 W x 20.98 H (inches) .675 L x .713 W x .533 H (meters) |

| Noise Output | < 72 dBC at 1 meter |

Arrangement

The Seakeeper 4.5 consists of the Flywheel, Enclosure, Foundation, Electronics, Brake, Cooling, and Cover Subsystems.

Installation Location

The Seakeeper is a torque device and does not have to be installed in a specific hull location or on the centerline. However, the Seakeeper should not be installed forward of the longitudinal center of gravity to minimize high acceleration loading due to hull/wave impacts during operation at high speed or in large waves.

Mounting Dimensions

See Drawing No. 90726 – Seakeeper 4.5 Bolt-In Installation Details.

Loads

The installer is responsible for designing the foundation to which the Seakeeper is attached and for ensuring that this foundation can safely transfer the concentrated Seakeeper loads from the frame to the adjacent hull structure. Loads that the Seakeeper imposes on the hull structure are explained on Drawing No. 90726 – Seakeeper 4.5 Bolt-In Installation Details; these loads do NOT include vessel motion accelerations, such as vertical slam loads which can be high for higher speed vessels.

Cooling

The Seakeeper bearings, Motor Drive Box, and hydraulic manifold are cooled by a closed water / glycol mix cooling loop that incorporates a seawater heat exchanger. The installer is responsible for providing 2.5 – 4 GPM (9.5 – 15.2 LPM) raw water at ambient sea temperature and a maximum pressure of 20 psi (1.4 bar) to the heat exchanger.

Electrical

The installer is responsible for supplying 110 VAC at 30 Amps or 230 VAC at 20 Amps, 50/60 Hz, Single Phase, service to the Motor Drive Box, 12 VDC at 15 A service to the Seakeeper Control System, and 12 VDC at 15 A service to the Seawater Pump. Separate circuit breakers should be used for each Motor Drive Box in multiple Seakeeper installations. Similarly, separate circuit breakers should be used for each Seakeeper Control System and Seawater Pump in multiple Seakeeper installations.

Operator Controls

A compatible MFD or a 5″ Touch Display is used to start, operate, monitor, and shutdown the Seakeeper from the helm. The operator may also use the local ConnectBox interface on the Seakeeper 4.5 to start and shutdown the Seakeeper.

Performance

Reduction of boat roll is a function of the boat’s displacement, transverse metacentric height (GMT) and hull damping as well as the operating conditions (speed and heading with respect to waves) and sea state. The Seakeeper controller regulates the active hydraulic brake to ensure the Seakeeper’s anti-roll torque is maximized regardless of hull characteristics or operating conditions.

Alarm and Monitoring

Sensors, alarms and shutdowns are provided to allow unattended operation. Sensors measure Seakeeper and drive temperatures, vacuum pressure, gimbal angle, brake pressure, and ship motion. The Seakeeper controller sends sensor values and alarm information to the display and also locks the brake and shuts down the motor drive in the event of an alarm condition. Seakeeper operating history during faults or alarms is recorded in the controller’s memory for subsequent recall if service is needed. Seakeeper may access the Seakeeper’s software to gather run hours, bearing loading, and hull slamming information.

Safety

The brake automatically locks the Seakeeper so it cannot generate excessive anti-rolling torque loads in the event of a system fault or alarm, loss of electrical power or loss of brake pressure. The brake can be locked from the Display or by shutting off AC and DC power at the supply breakers.

8.0 Revision History

| REVISION | DESCRIPTION | DATE |

| 1 | Initial release. | 09NOV2023 |