Mechanical Installation Manual (750, 750 Quad)

6. Measure Transom Angle

Measure Transom Angle Introduction

Seakeeper Ride Controllers must be mounted as close to flush and parallel with the running surface of the hull as possible, as explained in Section 5. This portion of the installation requires installer to measure the transom angle at the chosen Controller locations.

The Ride 750 Series controllers allow for some adjustment in seal plate angle after installation to fine tune the equipment. We strongly recommend attempting to install the equipment as precisely as possible to achieve a flush and parallel Seal Plate. If the Seal Plate angle needs to be adjusted after adhesive cure it can be done.

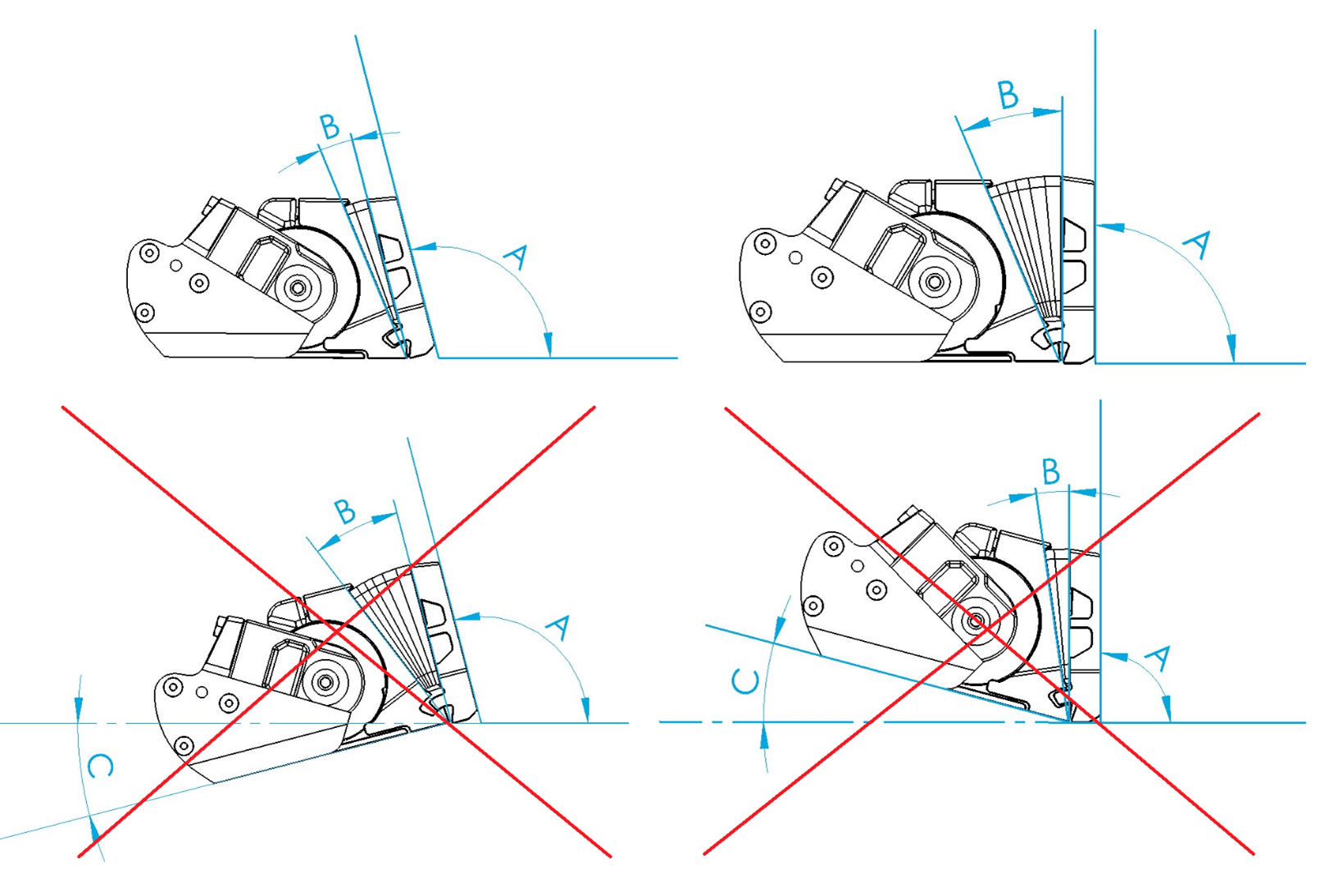

The Wedge Pack Assembly (Items 4, 5, 6, 7, and 8 in Inventory Parts) allows for the adjustment of the Controllers to the boat’s transom angle. The figure below illustrates the differences in the angle between the aft end of the running surface and the transom (A) and the resulting effects on Wedge Pack selection (B). The top two images show correct angle adjustments. The bottom two images show incorrect angle adjustments.

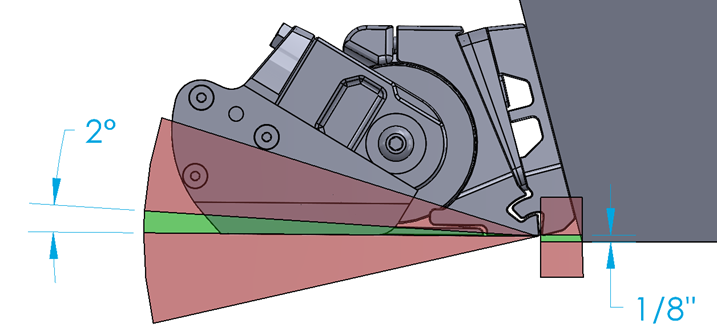

For optimal performance, the Seal Plate must be completely flush with the aft end of the running surface of the boat, which will eliminate angle C in the figure above. The Seal Plate can angle upward up to 2 degrees with a negligible effect on system performance. DO NOT mount the Controller angled upward more than 2 degrees. DO NOT mount the Controller angled downward at all.

6.1 Measurement Steps

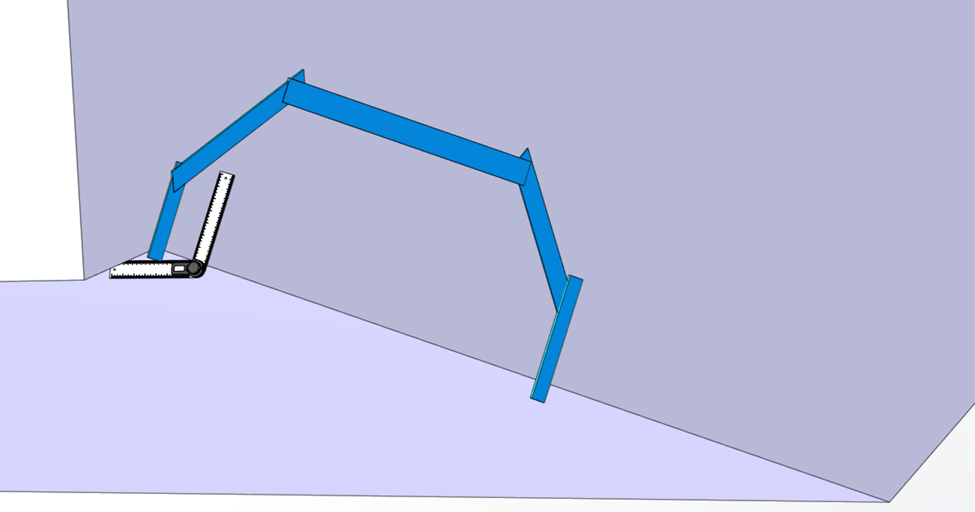

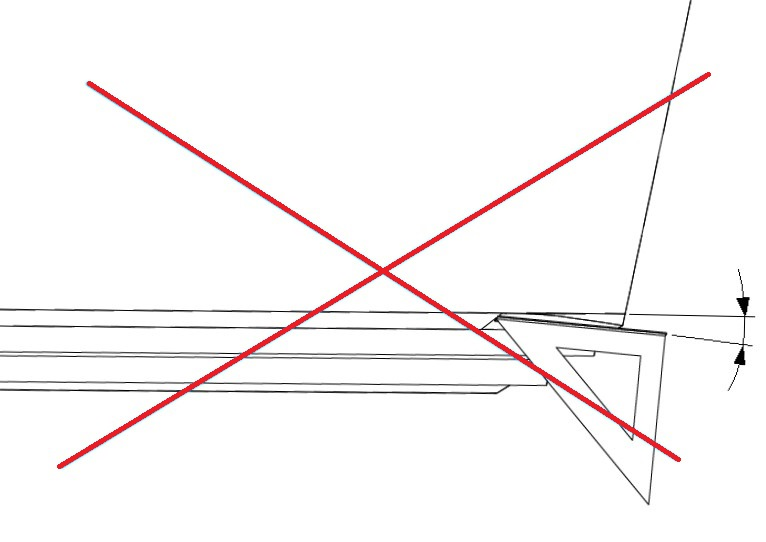

- Using the selected Controller locations from Section 5, measure the angle with a digital protractor from the running surface to the transom, perpendicular to the deadrise. See the figure below for an example of the measurement on the port Controller, outboard location.

- Measure the inboard and outboard ends of the port 1 Controller area and use the larger angle in the following Sections. Round up to the nearest degree.

- Measure inboard and outboard ends of the starboard Controller area and use the larger angle in the following Sections. Round up to the nearest degree. As with every step, repeat measurement process for both port and starboard sides. Note: It is possible to find different angles between port and starboard side of the hull.

- For Quad Systems

- Measure the inboard and outboard ends of the port 2 Controller area and use the larger angle in the following Sections. Round up to the nearest degree. Note: It is possible to find different angles between port 1 and port 2 locations.

- Measure the inboard and outboard ends of the starboard 2 Controller area and use the larger angle in the following Sections. Round up to the nearest degree. Note: It is possible to find different angles between starboard 1 and starboard 2 locations.

5. Determine the number of Wedge Plates required for each Controller’s Wedge Pack using the transom angle measured previously and Table 3.

The transom and Wedge angles indicated in the Table 3 are the maximum range of the product. If the boat’s transom angle is outside the range of Table 3, do not add or remove more Wedges to accommodate the different angle. Contact Seakeeper to determine the best course of action.

Table 3 – Transom Angle and Wedge Plates

| TRANSOM ANGLE | 3 DEGREE | 4 DEGREE | 5 DEGREE | Top Bolt | Bottom Bolt |

| 90 | 3 | 1 | 2 | 75MM BOLT LENGTH | 40mm BOLT LENGTH |

| 91 | 3 | 2 | 1 | ||

| 92 | 1 | 2 | 2 | ||

| 93 | 2 | 1 | 2 | ||

| 94 | 3 | 2 | |||

| 95 | 3 | 1 | 1 | ||

| 96 | 1 | 1 | 2 | ||

| 97 | 2 | 2 | |||

| 98 | 2 | 1 | 1 | ||

| 99 | 2 | 2 | |||

| 100 | 1 | 2 | |||

| 101 | 1 | 1 | 1 | 55mm BOLT LENGTH | 35mm BOLT LENGTH |

| 102 | 2 | 1 | |||

| 103 | 2 | 1 | |||

| 104 | 3 | ||||

| 105 | 1 | 1 | |||

| 106 | 1 | 1 | |||

| 107 | 2 | ||||

| 108 | 1 | ||||

| 109 | 1 | ||||

| 110 | 1 |

6.2 Hulls with Unique Stern Features

For many planing hulls, the aft portion of the running surface is straight, however, there can be exceptions where there is a curvature, angle, or twist just forward of the transom. This may be referred to as a stern wedge, hook, or rocker. These types of features are generally added to the hull to improve handling characteristics or induce a constant trim, adding a bow down moment during normal running conditions.

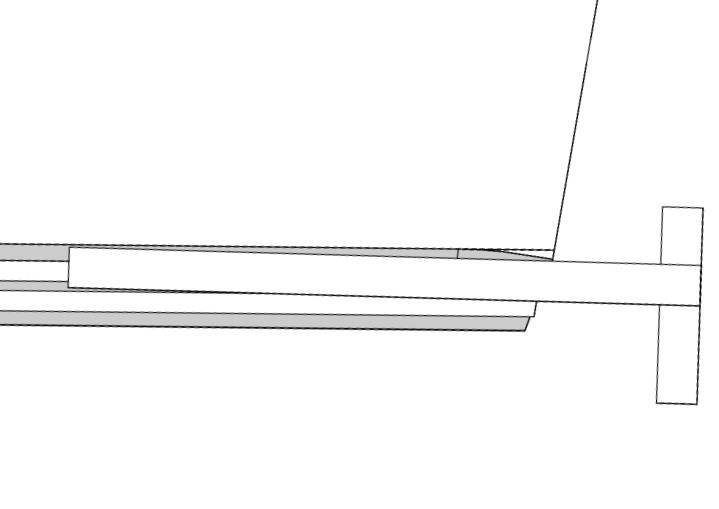

Be sure to use a 3-ft (0.9 m) straight edge along the hull bottom when evaluating the transom angles to obtain a correct assessment of the running surface.

If the Seal Plate were to be installed following the same angle as a stern wedge, it would create a permanent additional upward force in the aft of the boat, and the bow would be pushed down irreversibly. This incorrect assessment for installation is demonstrated below.

Measure the angle of the transom over a greater length of the running surface up to 3-ft (0.9 m) to ensure the proper angle.