Seakeeper 6 Installation Manual (90402-6) 6-254-8146 to Current

3.0 Electrical Installation

3.1 Electrical Installation Introduction

This section for electrical installation explains how to mount the electrical equipment and how to connect the electrical cables.

Reference Documents & Drawings:

- 90396 – Seakeeper 6 Cable Block Diagram

- 90403 – Seakeeper 6 Operation Manual

- TB-90191 -Seawater Cooling Pump Recommendations

- 90558 – ConnectBox Helm Mounting Kit

- TB-90640 – ConnectBox Connection Requirements

- Seakeeper Compatibility Technical Bulletins

- Optional 5″ Touch Display

16.4 ft (5 m), P/N 20248

82 ft (25 m), P/N 30355

19.7 ft (6 m), P/N 30332

16.4 ft (5 m), P/N 20334

16.4 ft (5 m), P/N 30327

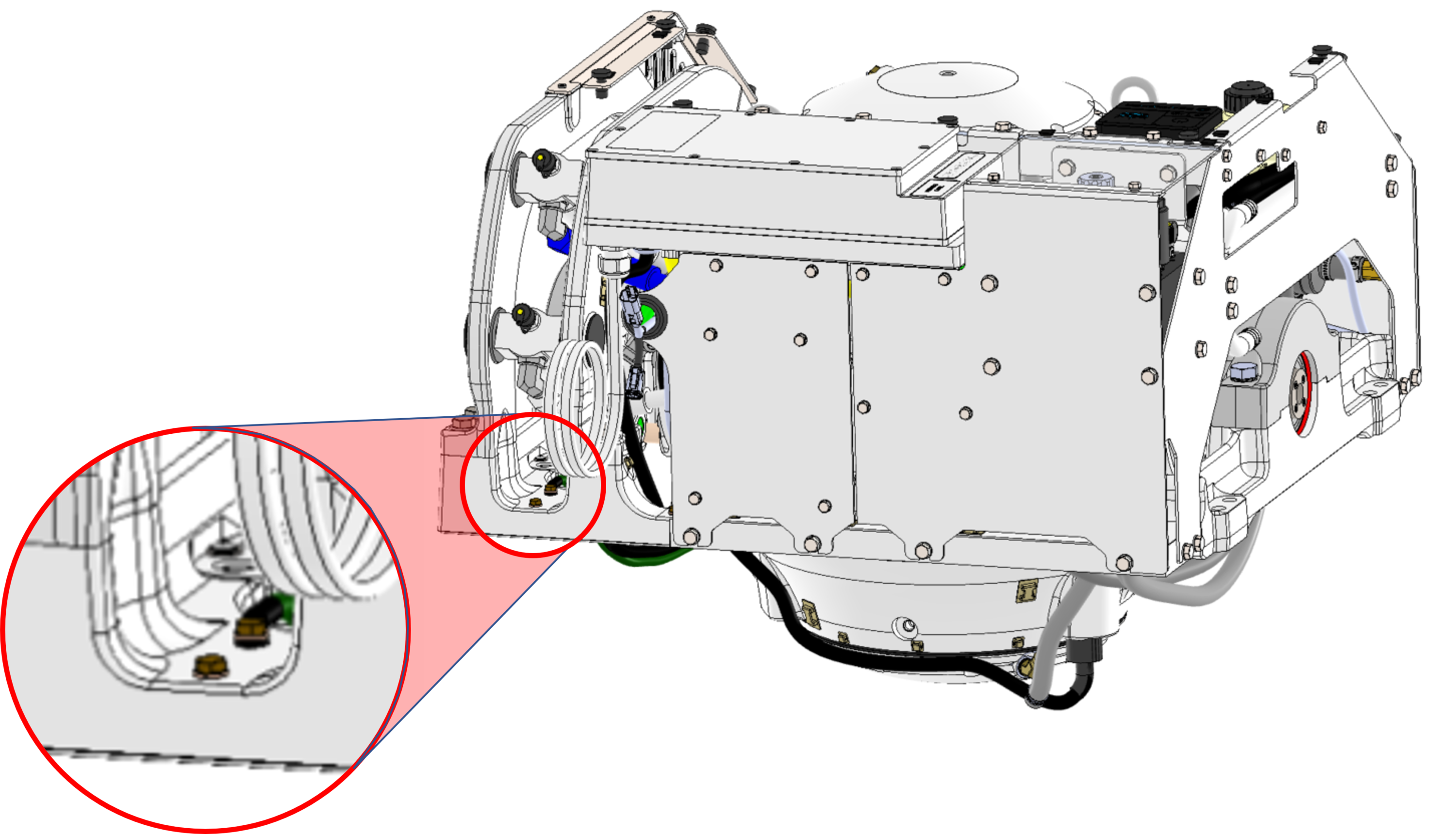

Figure 30 – Electrical Equipment for Seakeeper 6

3.2 Electrical Equipment Power Connections

AC Input Power Source Requirements

- Either of two AC input voltages are acceptable:

- 110 – 120 VAC (nominal) (+/- 10%), 1 Phase, 50/60 Hz, 30 A

- 208 – 230 VAC (nominal) (+/- 10%), 1 Phase, 50/60 Hz, 20 A

- A separate circuit breaker should be used for each Seakeeper Drive Box in multiple Seakeeper installations.

Drive Box AC Power Input Connection Instructions

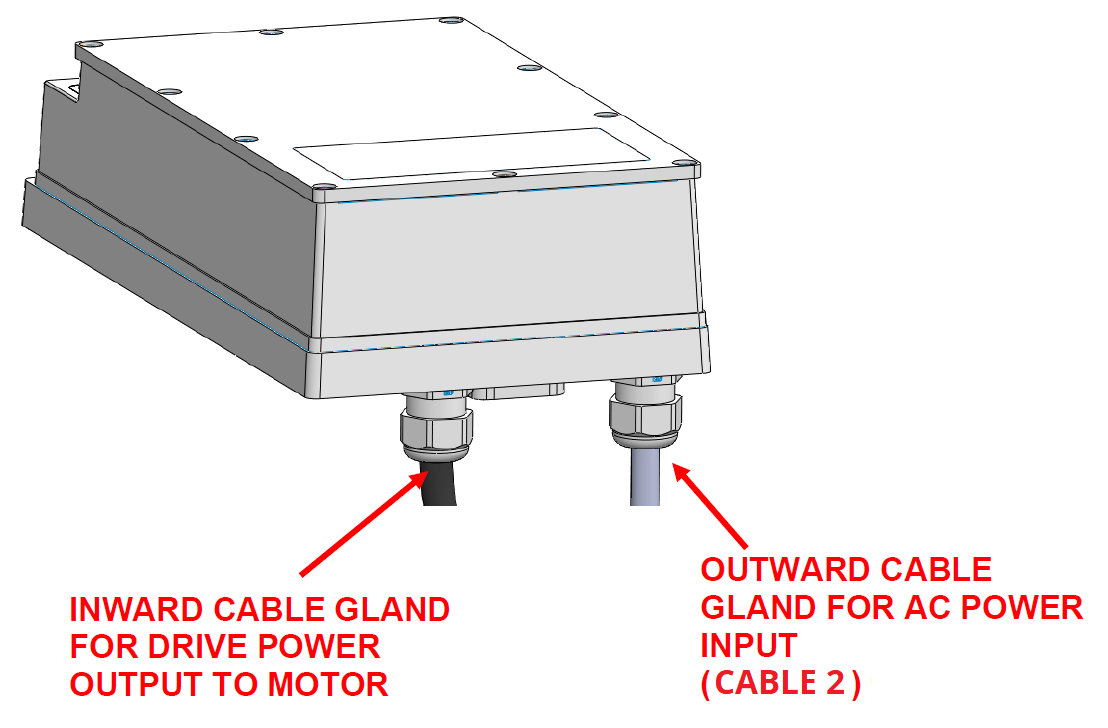

- Cable: 3 x 10 AWG (3 x 6mm2 CSA), 10 ft (3 m) length, Seakeeper supplied pre-installed.

- Locate AC Power Input Cable to the Drive Box at the outward of two cable glands per Figure 32.

- Connect AC wires to a 230 V, 20 A (or 110 V, 30 A), double-pole Circuit Breaker at an AC power distribution panel.

Low Current 12 V Power Input

- One 12 VDC, 15 A (Customer supplied) for Seakeeper Control Power, AND

- One 12 VDC, 15 A OR 24 VDC, 10 A (Customer supplied) for DC Seawater Pump.

- A dedicated breaker should be used for Seakeeper control and Seawater Pump power for each Seakeeper unit.

Seakeeper DC Control Power Connection Instructions

Reversing polarity on the DC power input to the Seakeeper can result in damaging the electronics in the control system.

- 12 VDC, 15 A, 2 x 12 AWG (3 x 4 mm2 CSA) customer supplied.

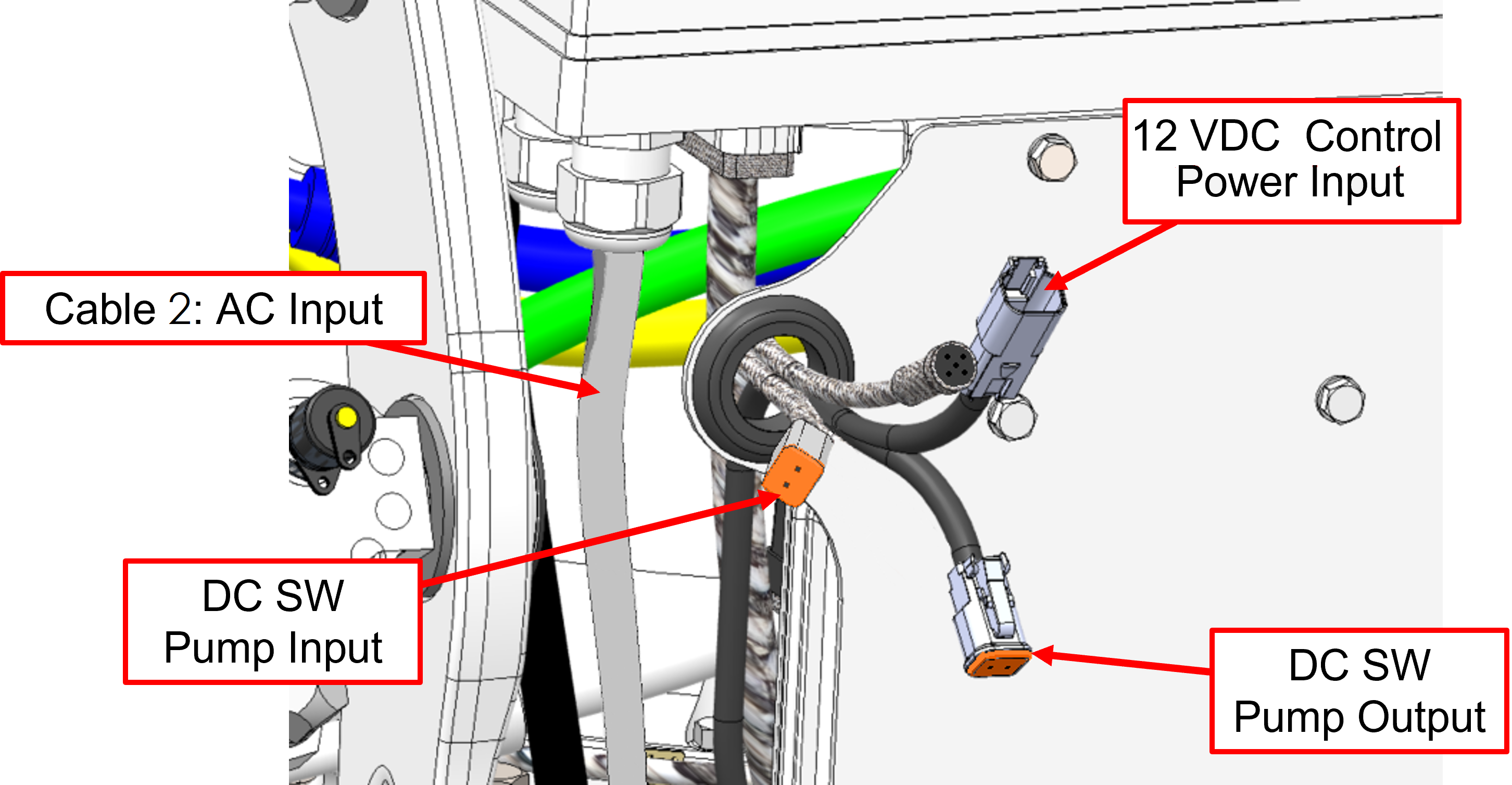

- Install Seakeeper provided DC Power Input Cable, P/N 20248 (shown in Drawing No.90396):

- Route DC Power Input Cable to DC Power Distribution Panel.

- Terminate positive (B+, Red) conductor through dedicated over-current protection device (customer supplied) and a dedicated Seakeeper isolation switch (customer supplied) then directly to battery plus terminal.

- Terminate negative (B-, Black) conductor directly to battery negative terminal or negative bus.

- Before connecting DC Power Input Cable to Seakeeper, check for proper voltage and polarity with a DC multimeter using Figure 33.

- Connect DC Power Input Cable to 12 VDC input receptacle on Seakeeper.

- Install Seakeeper provided DC Power Input Cable, P/N 20248 (shown in Drawing No.90396):

When energizing DC power the first time, if ConnectBox does not power up immediately then disconnect and inspect connector polarity.

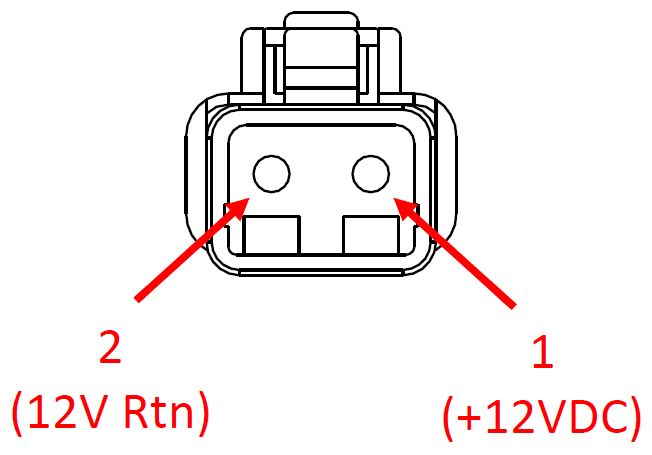

DC Seawater Pump 12 VDC Power Input Connection Instructions

Connecting the DC Seawater pump in any other manner than recommended by Seakeeper may cause internal failure.

- Install DC SW Pump Input Power Cable (P/N: 30327) to Seakeeper 6 “SW Pump DC In” (shown in Drawing No. 90396) with overcurrent protection corresponding to seawater pump selected.

- Connect the 16 AWG positive conductor (red) through dedicated overcurrent protection device (customer-supplied), maximum of 15 A, to dedicated battery isolation switch.

- 24 VDC, 10 A max can be used for Seawater Pump power.

- Connect the 16 AWG negative conductor (black) directly to battery negative terminal or DC main negative bus bar.

- Before connecting DC SW Pump Input Power Cable to Seakeeper, check for proper voltage and polarity with a DC multimeter using Figure 34.

- Connect DC SW Pump Power Input Cable to Seawater Pump 12 VDC In connector on the Seakeeper, DEUTSCH DT04-2P connector.

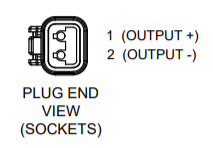

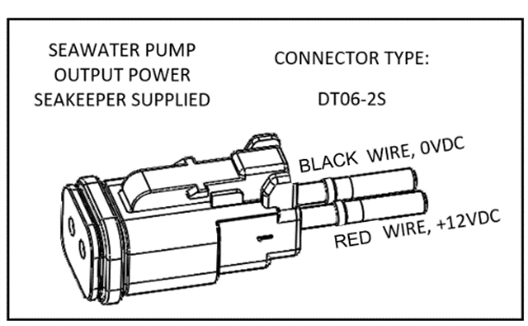

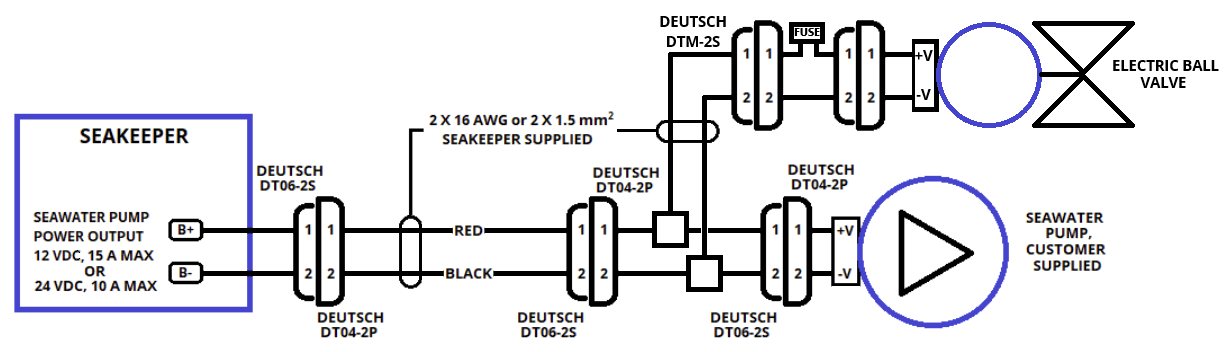

DC Seawater Pump 12 VDC Power Output Connection Instructions

- Connect DC SW Pump Power Output Cable (P/N 20334) to the Seakeeper 6 wire harness connector “SW Pump 12VDC Out” for DC power output to the seawater pump.

- Seawater Pump Output Power Cable is a 2 x 16AWG cable, 16 ft (5 m) length, with a size 16 female Deutsch plug.

- Pumps rated at 12 VDC, 15 A maximum (24 VDC, 10 A), customer-supplied, must be configured with a Deutsch DT series, 2-pin receptacle to mate with the connector shown in Figure 35.

- The DC SW Pump Power Output Cable must be routed and installed in the vessel from the Seakeeper 6 “SW Pump 12VDC Out” Deutsch connector (pins end) to the Y-Branch SW Pump Output & Valve Cable (P/N 20742) (socket end).

- Connect Y-branch cable plug end (socket end) to the customer-supplied receptacle end (pins end). The recommended wiring is shown in Figure 36.

- Connect Y-branch cable DTM-2S connector to DTM-2P connector of fused cable (P/N 20794) and the electric valve.

- Contact Seakeeper if desired to install customer-supplied relay on DC SW Pump Power Output Cable to power Seawater Pump and valve.

3.3 Electrical Equipment Ground Connections

Seakeeper to Vessel Ground Connection Instructions

- Connect the Seakeeper foundation ground to vessel ground as shown in Figure 7.

- Install Ground Cable (10 AWG or 6.0 mm2, Customer supplied) from the M6 brass ground stud on the Seakeeper rear brace to a suitable vessel ground.

- EN/IEC 90204-1: 2016, Clauses 6.3.3 and 8.2.3

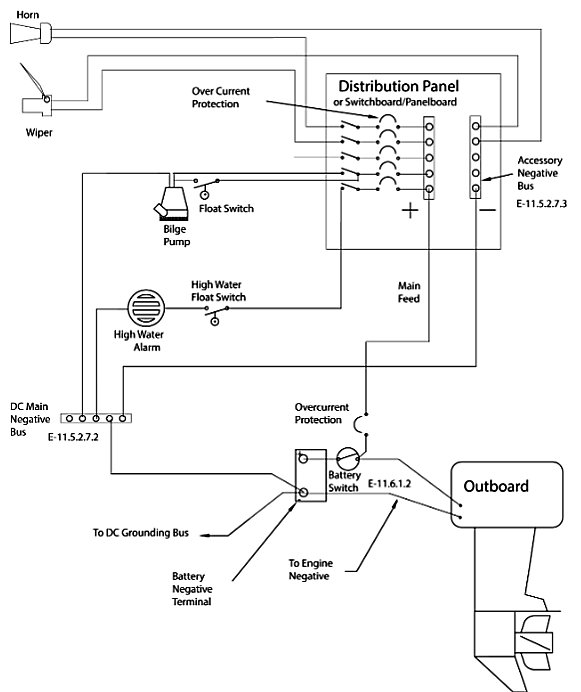

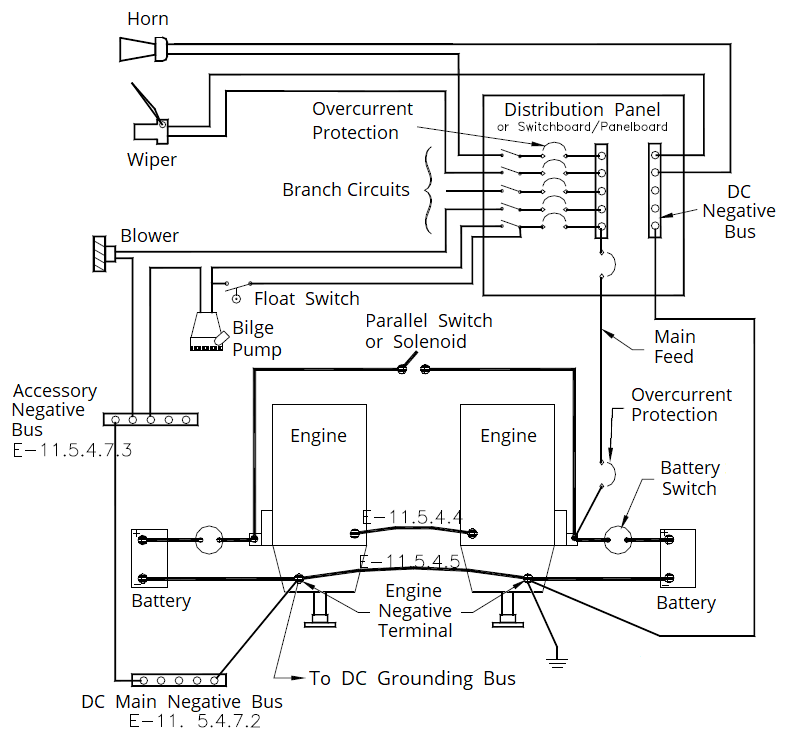

- ABYC E-11 July 2021, Clauses 11.5.2 and 11.17

NOTE: USE ONLY THIS LOCATION FOR GROUNDING THE SEAKEEPER TO THE VESSEL GROUND.

- Ground connection should be made with vessel bonding system, if available. However, the ground is not referring specifically to a bonding system but for outboard boats generally refers to the outboard engine negative terminal. Per ABYC E-11 (2018), Clause 11.5.2.7.4: If the negative side of the DC system is to be connected to the ground, the connection shall be made only from the engine negative terminal, or its bus, to the DC grounding bus. This connection shall be used only as a means of maintaining the negative side of the circuit at ground potential and is not to carry current under normal operating conditions.

- A proper ground connection is critically important for corrosion protection and helps to ensure the ignition protection of the unit by ensuring it does not carry any stray current.

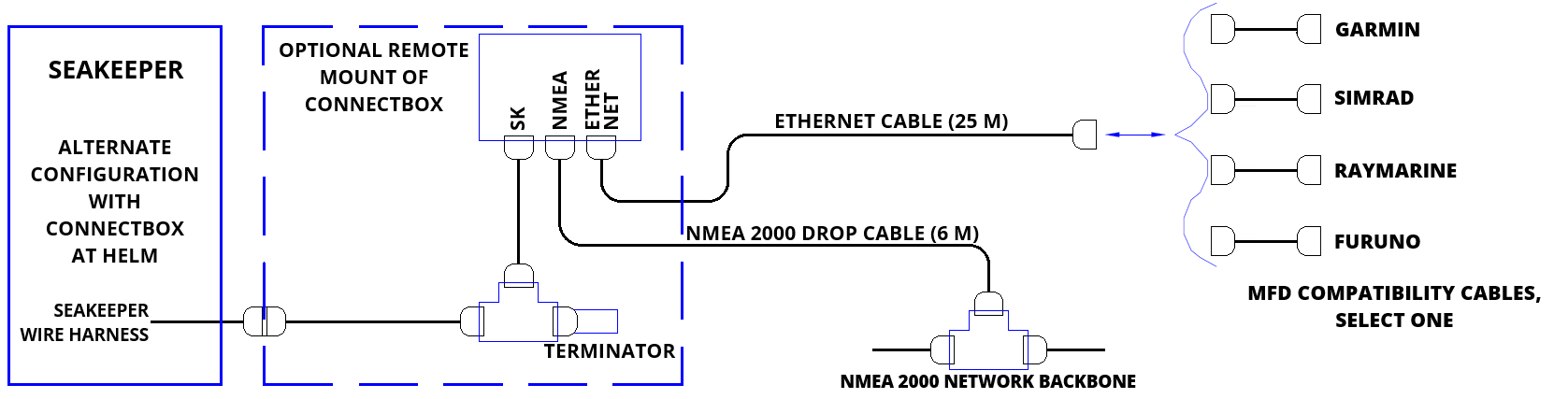

3.4 ConnectBox Display Connections

Seakeeper 6 Display Options

A compatible multi-function display (MFD) is required with the installation of a Seakeeper 6 to support the full functionality of the unit through the Seakeeper App in addition to the ConnectBox. The Seakeeper App provides an interface for controlling the Seakeeper or viewing the Settings, Service, Info, and Alarm pages. The Seakeeper ConnectBox can be helm-mounted to provide an additional interface for the control of the Seakeeper but does not replace the need for a compatible display.

The Seakeeper 6 has several options for establishing a Seakeeper display interface to support the Seakeeper App:

- Preferably, connect the Seakeeper to a compatible Multifunction Display (MFD) (Fig. 40A).

- A combination of a compatible MFD with a remote-mounted ConnectBox is also available (Fig. 40B).

Figure 40 provides a schematic of the preferred display option. The subsequent sections outline the instructions and references for connecting the Seakeeper 6 in each of these display options.

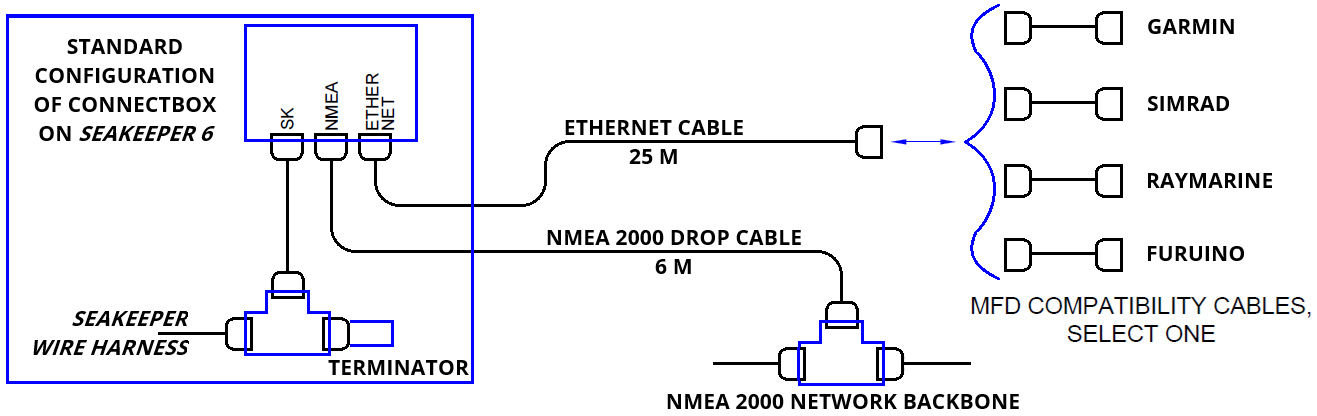

Connecting to a Compatible MFD

- The Seakeeper 6 can be connected to a variety of available MFD systems. Refer to the Technical Bulletins Section of the Seakeeper Technical Library for manufacturer specific MFD compatibility technical bulletins.

- MFD specific Technical Bulletins will be updated regularly as new MFD systems become compatible. Currently GARMIN, RAYMARINE, NAVICO (Simrad, Lowrance, B&G), and FURUNO offer compatible MFD models.

- Once a compatible MFD has been selected, refer to the appropriate manufacturer specific Technical Bulletin for integration instructions.

- Connect Seakeeper-supplied M12 D-Code, 32.8 ft (10 m), cable (P/N 30330) to MFD manufacturer-specific Ethernet adapter cable. Custom Ethernet cables for specific MFD manufacturers are available through Seakeeper and must be purchased with the Seakeeper 6 if connecting to an MFD.

NOTE: The ethernet cable MUST be connected to the ConnectBox.

The Seakeeper 6 will not work properly if the ethernet cable is

connected to the optional 5″ Touch Display.

NMEA 2000 Network Connection

The Seakeeper 6 requires a connection to the vessel’s NMEA 2000 network backbone via a drop cable for access to the GPS signal. The Seakeeper 6 will monitor information on the NMEA network to support and optimize the performance of the Seakeeper 6. If no GPS signal is detected, a warning will appear on the Seakeeper display. The Seakeeper will not spool-down, but the operation of the unit will be limited until the GPS signal returns.

- Install customer-supplied NMEA 2000 Tee Adapter (space required: approximately 4 W X 3 H in. (102 X 76 mm).

- Connect NMEA Backbone to Tee Adapter.

NOTE: NMEA drop cable can be no longer than 19.6 ft (6 m) in length. - Connect Seakeeper-supplied NMEA cable (P/N: 30332) to the customer-supplied NMEA 2000 Tee Adapter on vessel’s NMEA 2000 backbone.

- An active NMEA 2000 compatible GPS signal is required on the vessel’s NMEA 2000 backbone to operate the Seakeeper 6.

- If no GPS signal is detected, a Speed Over Ground (SOG signal) warning will be present on the Seakeeper app. See TB-90640 for NMEA connectivity guidance.

- An active NMEA 2000 compatible GPS signal is required on the vessel’s NMEA 2000 backbone to operate the Seakeeper 6.

ConnectBox Helm Mounting – Optional

The ConnectBox helm mounting may be considered when replacing an earlier Seakeeper model with a 5″ Touch Display and connecting to a compatible MFD. This configuration eliminates the need to run an Ethernet cable from the Seakeeper to the MFD.

- Console space required: Approx. 3.41 L x 4.15 W in. (87 x 106 mm).

- Mounting Instructions, Surface Mount: Refer to Drawing No. 90558 – Seakeeper ConnectBox Helm Mounting Kit for details. Seakeeper ConnectBox 3D Model available upon request.

- Mount the ConnectBox Replacement Blank insert into the Seakeeper 6 top cover at the original location of the ConnectBox.