Seakeeper 1 Installation Manual (90519-1)

Adding Coolant

- The Seakeeper 1 cooling system is filled to proper level when shipped, with a mixture of 50% ethylene glycol and 50% distilled water.

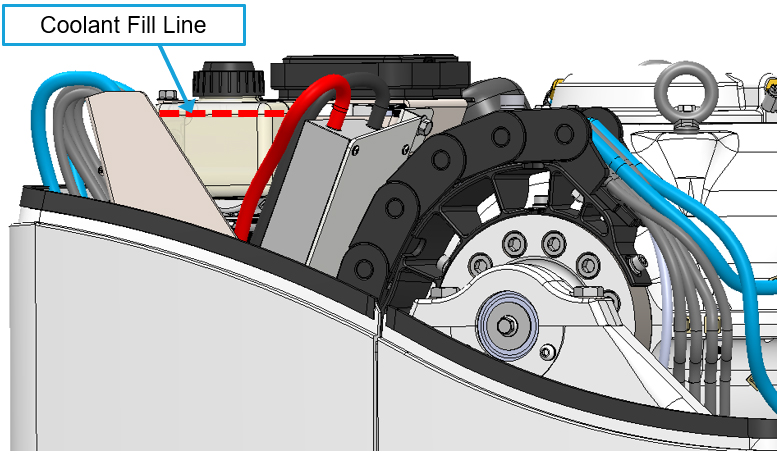

- The coolant reservoir should be filled with colored coolant mixture, as shown in the following figure. If level has dropped, check for evidence of leaks at all connections before adding fluid as described below.

- If coolant is at the correct level, (see Figure 2) skip to the Connecting Seawater to Heat Exchanger section.

- Mix 50% ethylene glycol with 50% distilled water in a clean container. Refer to glycol manufacturer’s literature for freezing points.

- Ethylene glycol with corrosion inhibitors is required. Most commercially available glycol has these additives standard.

- Remove reservoir cap and pour mixture in until level reaches top face of the reservoir enclosure, as shown in Figure 2.

- Filling reservoir above this level will not cause any damage but coolant may be expelled from the vented cap due to normal thermal expansion of coolant.

- Once the Seakeeper 1 and DC Seawater pump are connected to 12 VDC power:

- Check the Seakeeper Display interface for any ALARMS.

- Cycle the Seakeeper 1, press the POWER ON button.

- The flywheel will start to spin and the glycol pump will start.

- Recheck glycol level with fluid circulating in coolant circuit to ensure the correct fill level is maintained.

- After several minutes of running, press POWER OFF button.

- The cooling system is self-purging. If small amounts of air are in the system, they should be dislodged during the first sea trial. Recheck level after sea trial and add fluid if required.