Seakeeper 1 Installation Manual (90519-2) 1-233-0631 to Current

3.2 Electrical Equipment Connections

3.2.1 High Current 12 VDC Power

| Source | Battery Bank, 12 VDC, Marine, Deep Cycle |

| Voltage Range | 11.2 – 14.7 VDC |

| Continuous Current | 55 A |

| Overcurrent Protection | 80 A (Customer Supplied) |

High Current 12 VDC Power Connection Instructions

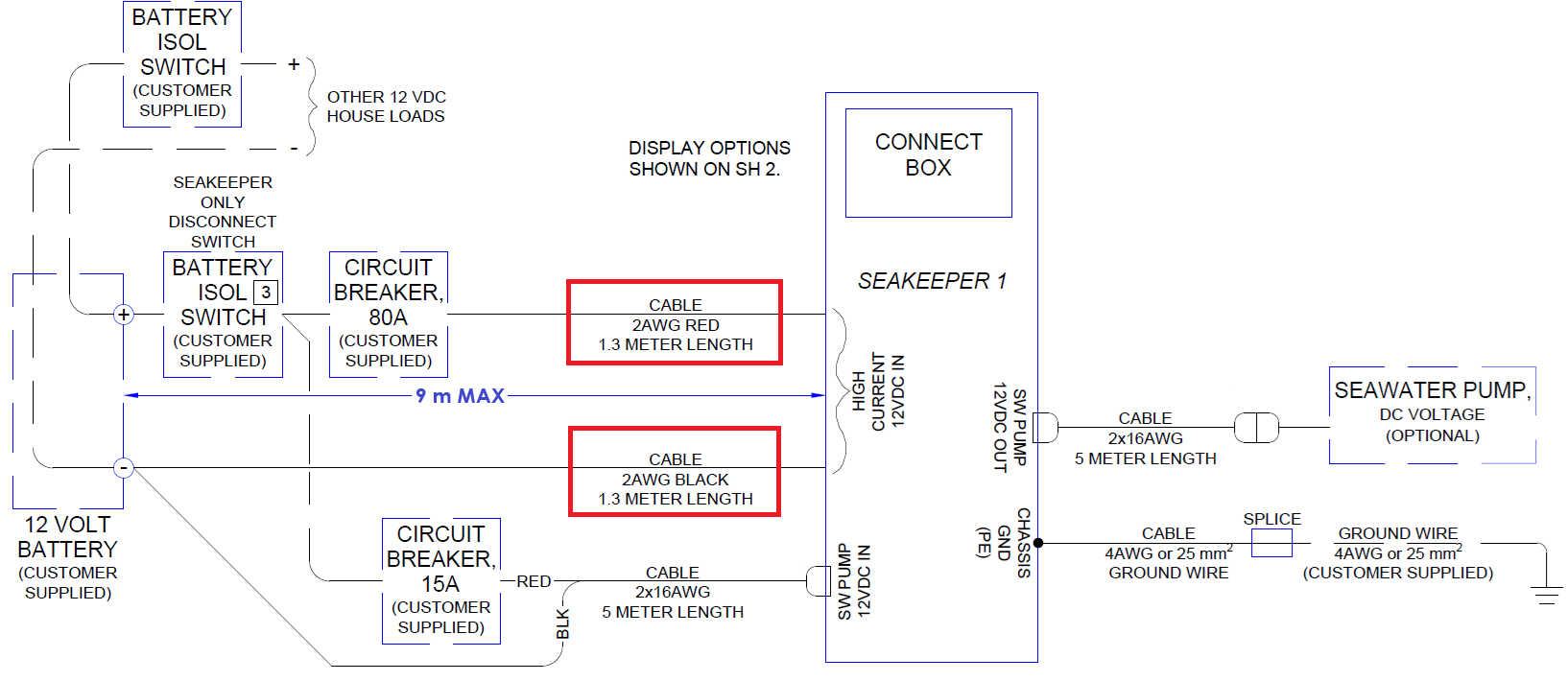

- Connect positive and negative High-Current 12 VDC cables, 2 AWG (33.6 mm2) conductors, to the 12 VDC power source.

- The positive and negative cables are supplied with a length of 1.8 m, and approximately 0.5 m is routed within the gyro frame (1.3 m outside frame).

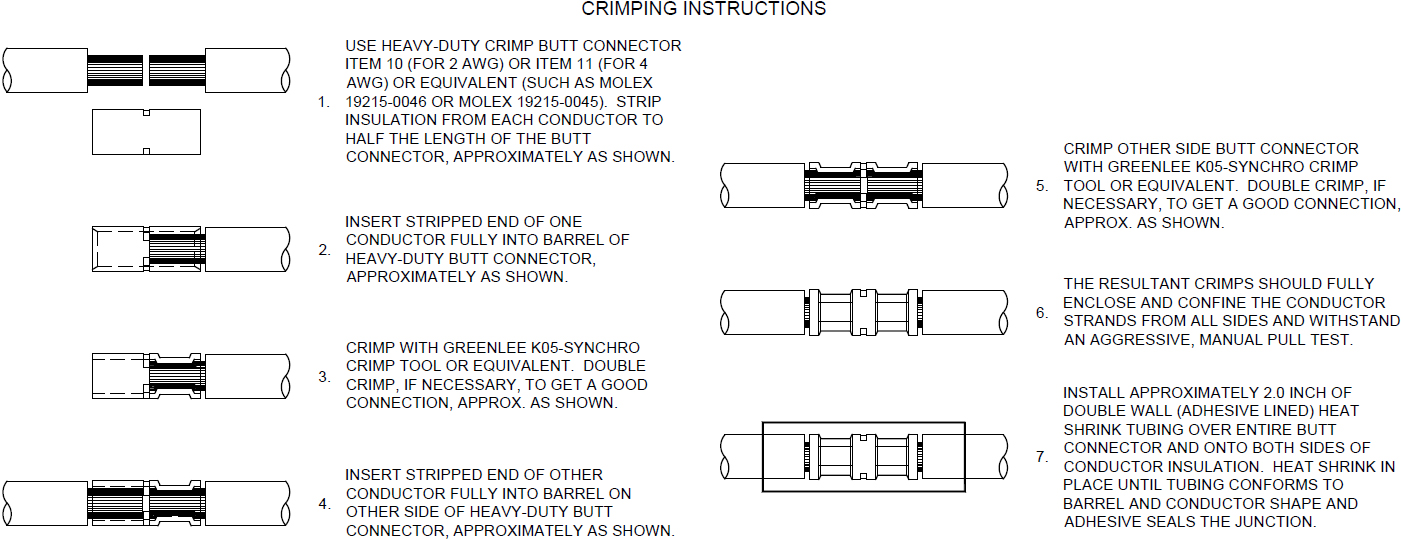

- Splice customer-supplied 2 AWG conductors to the positive and negative 2 AWG cables per the Crimping Instructions of Figure 4, using Seakeeper-supplied butt connectors, to increase conductors to the desired length. The maximum cable length is 29.53 ft (9.0 m) each. See also Figure 4 below for splicing.

- Crimp the positive High-Current Cable to B+ Conductor (red). Conductor should be continuous throughout entire length; do not coil. The most direct route to the 12 VDC power source should be used.

- Repeat Step 3 for the negative High-Current Cable to B- Conductor (black).

- Install approximately 2 in. (51 mm) of double wall (adhesive lined) heat shrink tubing over entire butt connector and onto both sides of conductor insulation.

- Connect positive conductor (B+, red) through dedicated 80 A overcurrent protection device (customer-supplied) and a dedicated isolation switch (customer-supplied), then directly to battery plus terminal or bus bar.

- Connect negative conductor (B-, black) directly to battery minus terminal or DC negative bus.

Figure 3 – Seakeeper 1 Cable Block Diagram (Drawing No. 90511) –

High Current Connection Highlighted

Reversing polarity on the DC power input to the Seakeeper can result in damaging the electronics in the control system.

Figure 4 – High Current DC Input Crimping Instructions

3.2.2 Seawater Pump 12 VDC Power

| Power Source | Battery Bank, 12 VDC, Marine, Deep Cycle |

| Voltage Range | 11.2 – 14.7 VDC |

| Current Rating | Max 15 A rating |

| Overcurrent Protection | Per pump specification, max 15 A |

Seawater Pump 12 VDC Power Input Connection Instructions

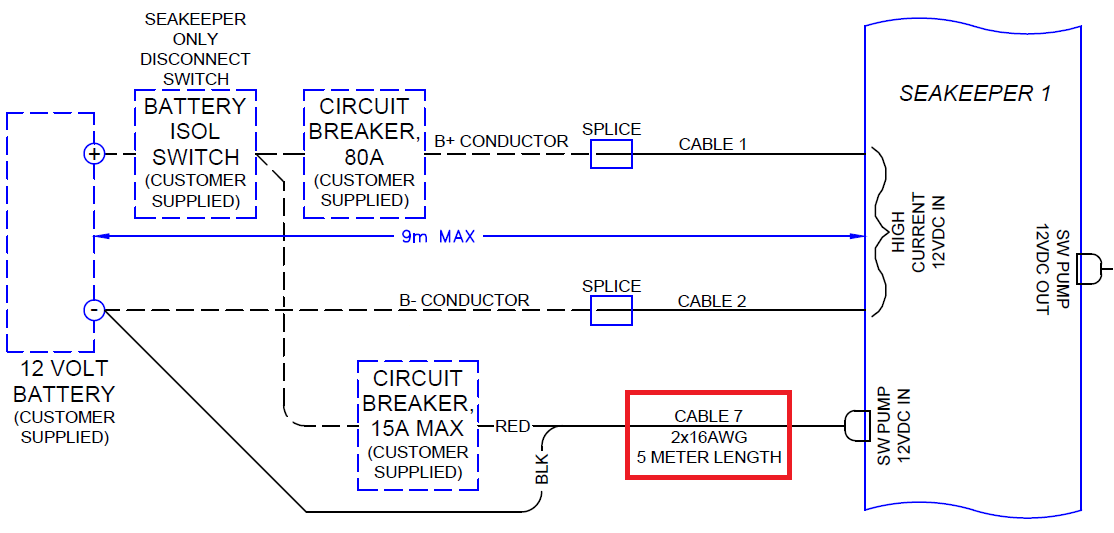

- Connect Seawater Pump Input Cable (P/N: 30327) to Seakeeper 1 “SW Pump DC In” as shown in Drawing No. 90511 – Seakeeper 1 Cable Block Diagram, with overcurrent protection corresponding to seawater pump selected.

- Connect the 16 AWG (1.5 mm2) plus conductor (red) through dedicated overcurrent protection device (customer-supplied), maximum of 15 A, to dedicated battery isolation switch.

- The positive High-Current 12 VDC cable, 2 AWG B+ conductor (red), is capable of carrying the current for both the High Current and Seawater Pump from the 12 VDC power supply to the battery isolation switch.

- Connect the 16 AWG (1.5 mm2) minus conductor (black) directly to battery minus terminal or DC main negative bus.

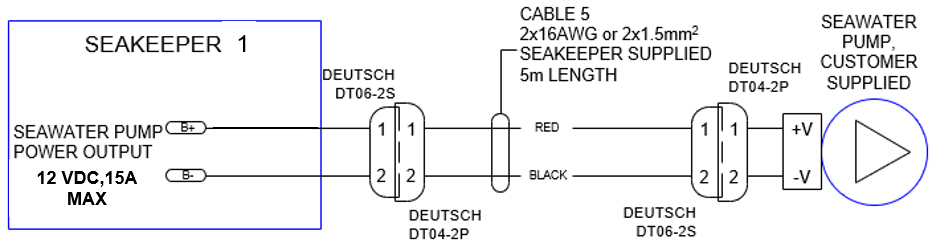

Seawater Pump 12 VDC Power Output Connection Instructions

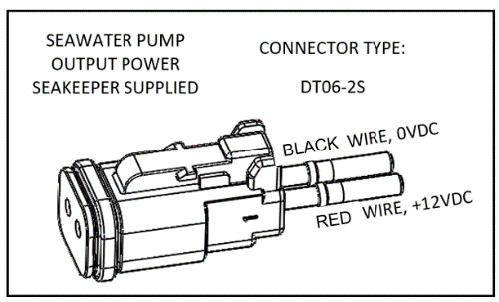

- Connect Seawater Pump Output Cable to the Seakeeper 1 “SW Pump 12 VDC Out” for DC power output to the seawater pump. The cable is a 2 x 16 AWG cable (1.5 mm2), 16 ft (5 m) length, with a size 16 female Deutsch plug.

- Pumps rated at 12 VDC, 15 A maximum, customer-supplied, must be configured with a Deutsch DT series, 2-pin receptacle to mate with the connector shown in figure 6.

- The Seawater Pump Output Cable must be routed and installed in the vessel from the Seakeeper 1 “SW Pump 12 VDC Out” Deutsch connector (pins end) to the DC seawater pump cable Deutsch connector (socket end).

- Connect Seawater Pump Output Cable plug end (female end) to the customer-supplied receptacle end (male end). The recommended wiring is shown in the following figure.

Figure 7 – Seawater Pump Power Output Cable

- Seakeeper DC Seawater Pump Assembly (P/N 30331), which is prewired for DC Seawater Output Cable, is available as an option with the Seakeeper 1.