Seakeeper 1 Installation Manual (90519-2) 1-233-0631 to Current

3.0 Electrical Installation

3.1 Electrical Installation Introduction

This section for electrical installation explains how to mount the electrical equipment and how to connect the electrical cables.

Reference Documents & Drawings:

- 90510 – Seakeeper 1 Hardware Scope of Supply

- 90511 – Seakeeper 1 Cable Block Diagram

- 90512 – Seakeeper 1 Cooling Water Schematic

- 90558 – ConnectBox Helm Mounting Kit

- TB-90191 – Seawater Cooling Pump Recommendations

- TB-90575 – DC Installation Kits

- Seakeeper Compatibility Technical Bulletins

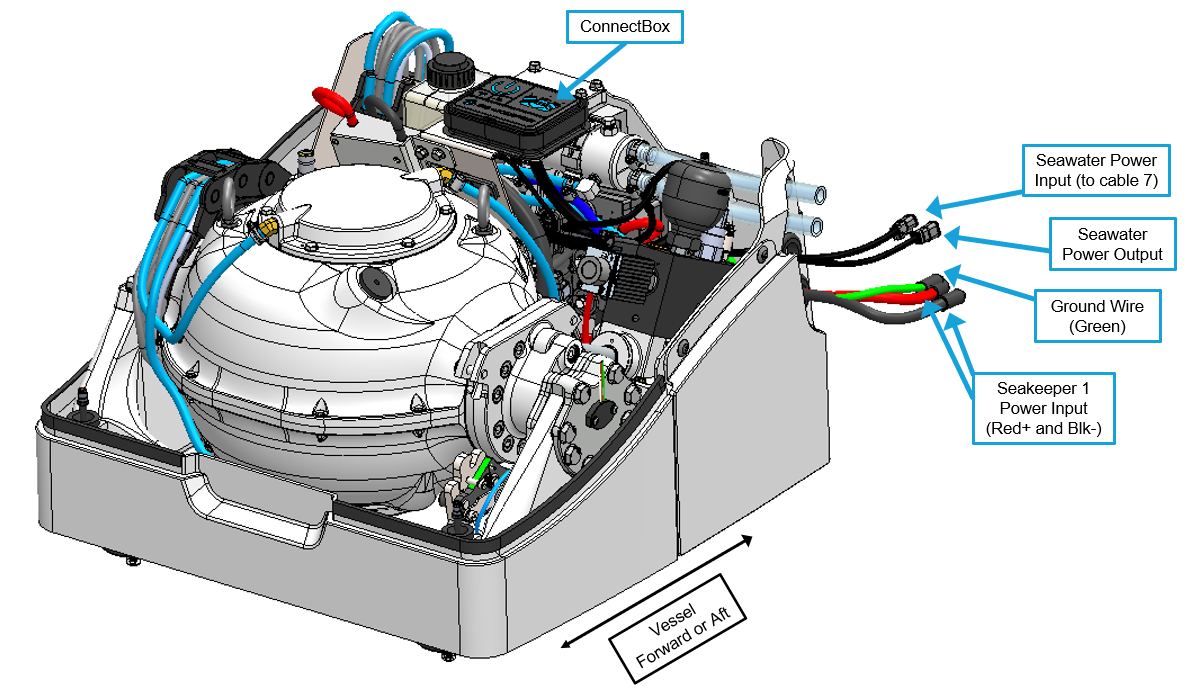

Figure 1 – Seakeeper 1 Isometric View with Electrical Connections

The following images show the electrical equipment included with the Seakeeper 1 Hardware Scope of Supply (Drawing No. 90510):

(20415)

(20436, 20435, 20437)

5 m. Length (30327)

5 m. Length (20334)

(30332)

(30330)

Figure 2 – Electrical Equipment for Seakeeper 1

3.2 Electrical Equipment Connections

3.2.1 High Current 12 VDC Power

| Source | Battery Bank, 12 VDC, Marine, Deep Cycle |

| Voltage Range | 11.2 – 14.7 VDC |

| Continuous Current | 55 A |

| Overcurrent Protection | 80 A (Customer Supplied) |

High Current 12 VDC Power Connection Instructions

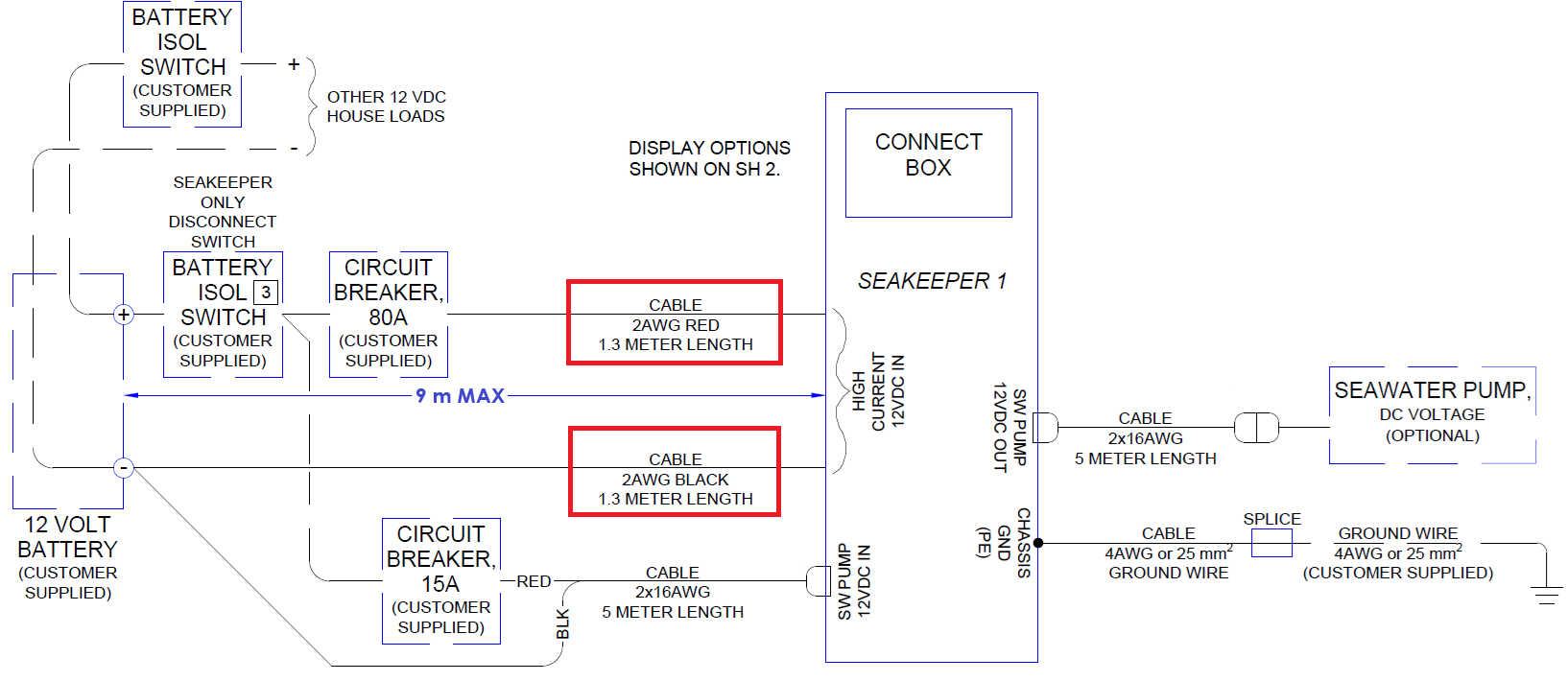

- Connect positive and negative High-Current 12 VDC cables, 2 AWG (33.6 mm2) conductors, to the 12 VDC power source.

- The positive and negative cables are supplied with a length of 1.8 m, and approximately 0.5 m is routed within the gyro frame (1.3 m outside frame).

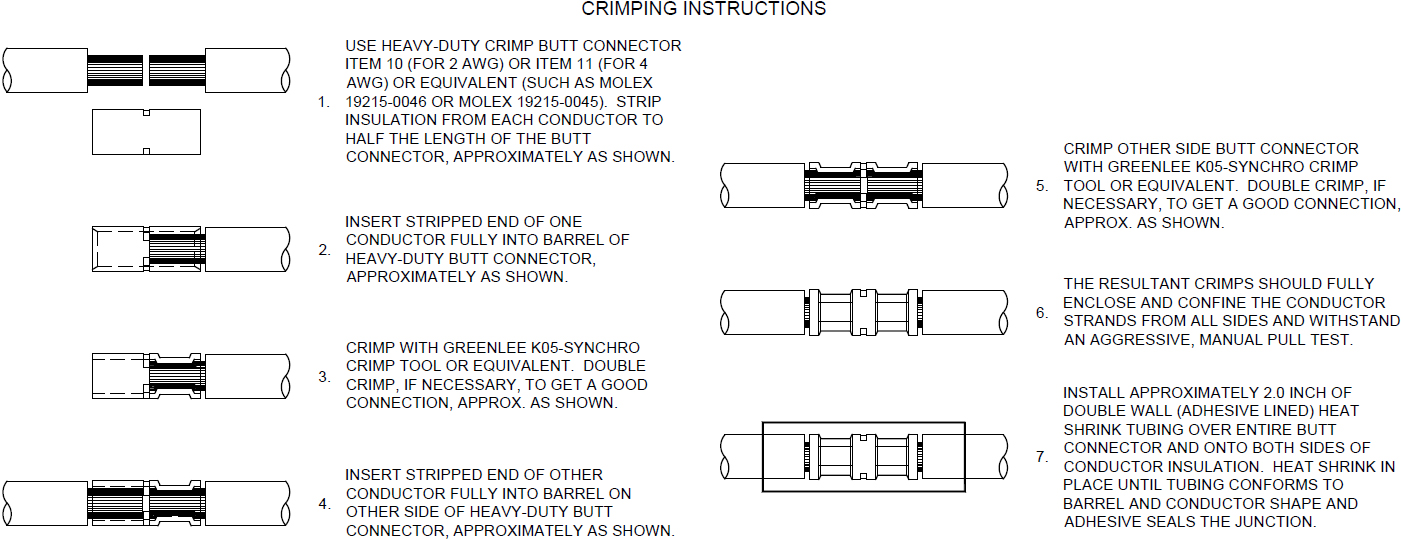

- Splice customer-supplied 2 AWG conductors to the positive and negative 2 AWG cables per the Crimping Instructions of Figure 4, using Seakeeper-supplied butt connectors, to increase conductors to the desired length. The maximum cable length is 29.53 ft (9.0 m) each. See also Figure 4 below for splicing.

- Crimp the positive High-Current Cable to B+ Conductor (red). Conductor should be continuous throughout entire length; do not coil. The most direct route to the 12 VDC power source should be used.

- Repeat Step 3 for the negative High-Current Cable to B- Conductor (black).

- Install approximately 2 in. (51 mm) of double wall (adhesive lined) heat shrink tubing over entire butt connector and onto both sides of conductor insulation.

- Connect positive conductor (B+, red) through dedicated 80 A overcurrent protection device (customer-supplied) and a dedicated isolation switch (customer-supplied), then directly to battery plus terminal or bus bar.

- Connect negative conductor (B-, black) directly to battery minus terminal or DC negative bus.

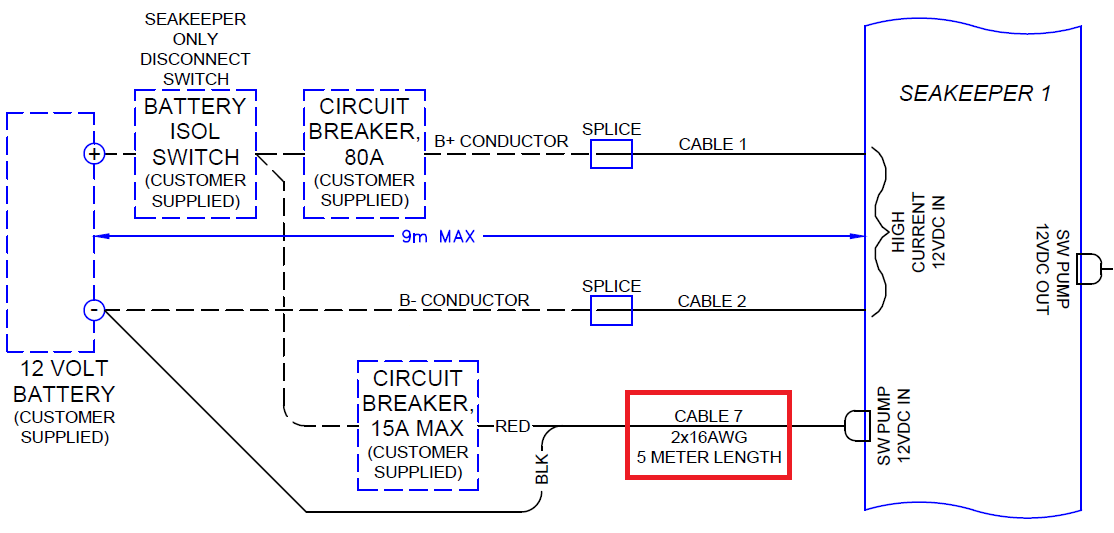

Figure 3 – Seakeeper 1 Cable Block Diagram (Drawing No. 90511) –

High Current Connection Highlighted

Reversing polarity on the DC power input to the Seakeeper can result in damaging the electronics in the control system.

Figure 4 – High Current DC Input Crimping Instructions

3.2.2 Seawater Pump 12 VDC Power

| Power Source | Battery Bank, 12 VDC, Marine, Deep Cycle |

| Voltage Range | 11.2 – 14.7 VDC |

| Current Rating | Max 15 A rating |

| Overcurrent Protection | Per pump specification, max 15 A |

Seawater Pump 12 VDC Power Input Connection Instructions

- Connect Seawater Pump Input Cable (P/N: 30327) to Seakeeper 1 “SW Pump DC In” as shown in Drawing No. 90511 – Seakeeper 1 Cable Block Diagram, with overcurrent protection corresponding to seawater pump selected.

- Connect the 16 AWG (1.5 mm2) plus conductor (red) through dedicated overcurrent protection device (customer-supplied), maximum of 15 A, to dedicated battery isolation switch.

- The positive High-Current 12 VDC cable, 2 AWG B+ conductor (red), is capable of carrying the current for both the High Current and Seawater Pump from the 12 VDC power supply to the battery isolation switch.

- Connect the 16 AWG (1.5 mm2) minus conductor (black) directly to battery minus terminal or DC main negative bus.

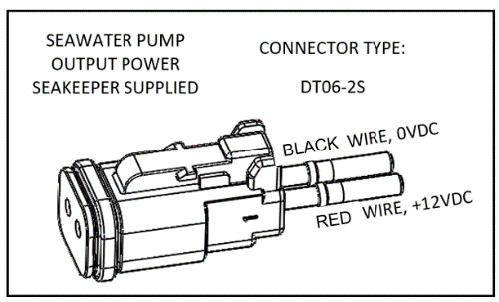

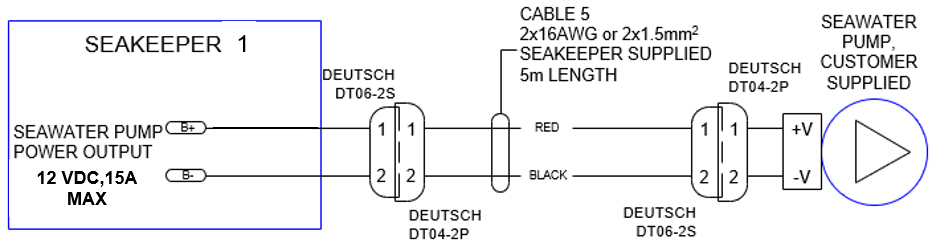

Seawater Pump 12 VDC Power Output Connection Instructions

- Connect Seawater Pump Output Cable to the Seakeeper 1 “SW Pump 12 VDC Out” for DC power output to the seawater pump. The cable is a 2 x 16 AWG cable (1.5 mm2), 16 ft (5 m) length, with a size 16 female Deutsch plug.

- Pumps rated at 12 VDC, 15 A maximum, customer-supplied, must be configured with a Deutsch DT series, 2-pin receptacle to mate with the connector shown in figure 6.

- The Seawater Pump Output Cable must be routed and installed in the vessel from the Seakeeper 1 “SW Pump 12 VDC Out” Deutsch connector (pins end) to the DC seawater pump cable Deutsch connector (socket end).

- Connect Seawater Pump Output Cable plug end (female end) to the customer-supplied receptacle end (male end). The recommended wiring is shown in the following figure.

Figure 7 – Seawater Pump Power Output Cable

- Seakeeper DC Seawater Pump Assembly (P/N 30331), which is prewired for DC Seawater Output Cable, is available as an option with the Seakeeper 1.

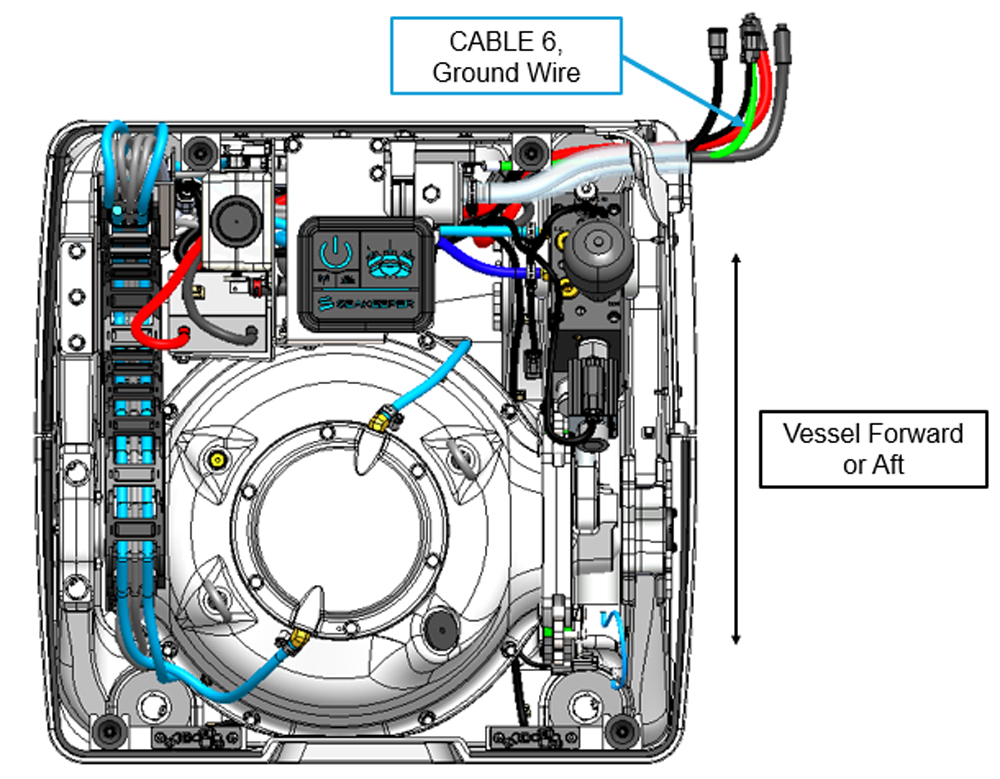

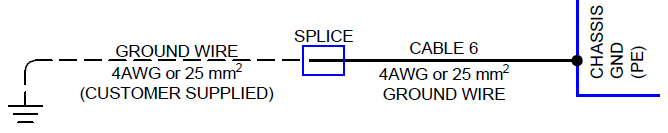

3.3 Electrical Equipment Ground Connections

Seakeeper 1 to Vessel Ground Connection Instructions

- Connect ground cable, 4 AWG (25 mm2), polyethylene (PE) cable to vessel grounding bus to comply with:

- EN/IEC 60204-1 Clauses 6.3.3 and 8.2.3.

- ABYC E-11 July 2021 Clauses 11.15.2 and 11.17.

- Butt splice green ground cable, 4 AWG (green) to a 4 AWG ground wire (customer-supplied) suitable in length for the specific installation, as shown in the following figure.

- Note: GROUND CABLE (GREEN) SHOULD ONLY BE USED FOR GROUNDING THE SEAKEEPER TO THE VESSEL GROUND.

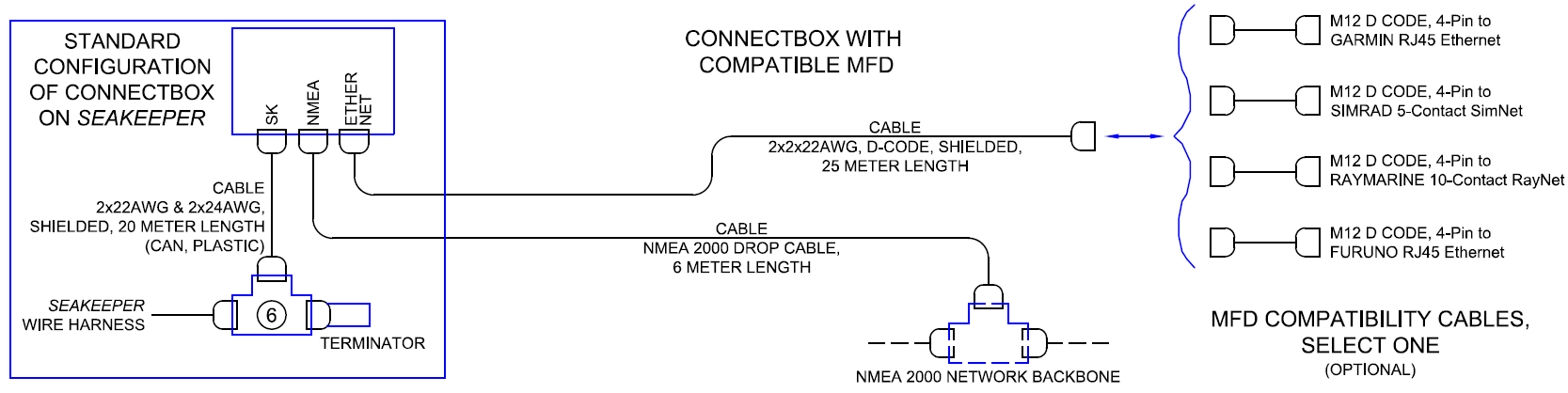

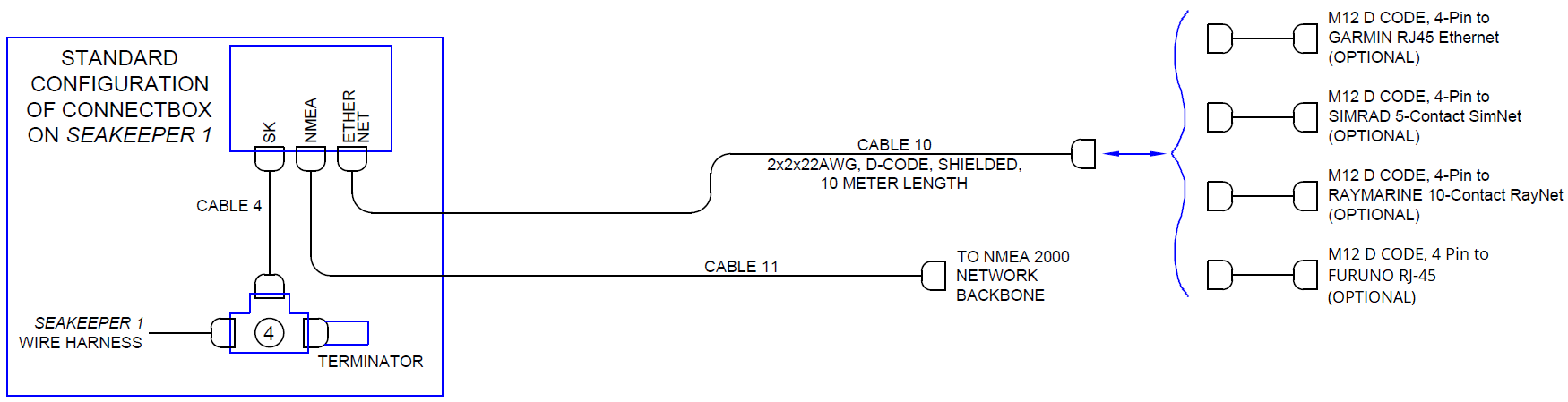

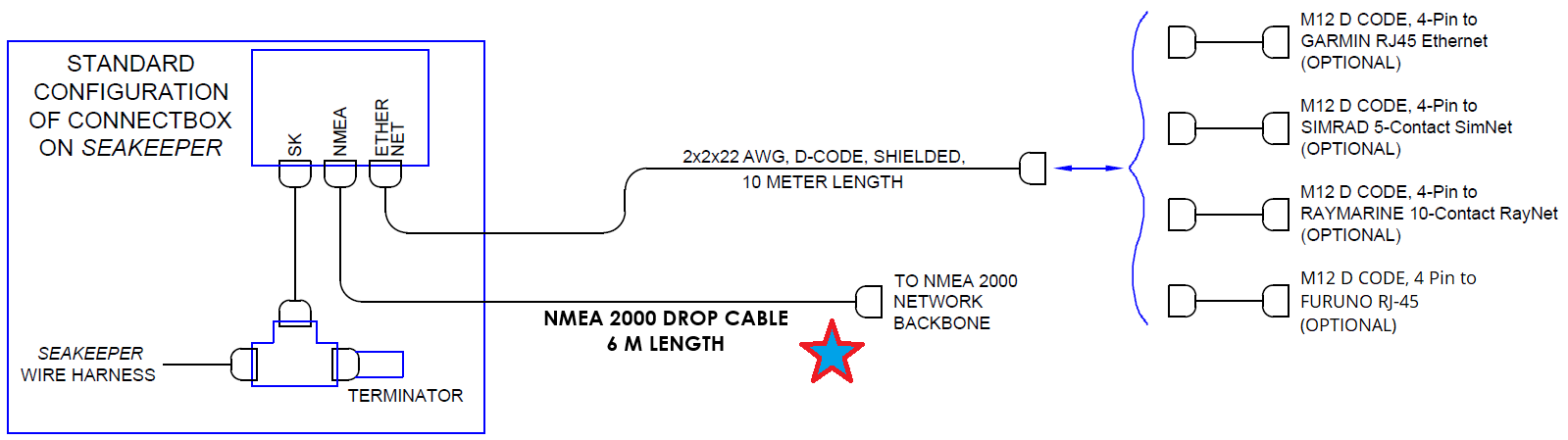

3.4 Seakeeper 1 Display Connection

Seakeeper 1 Display Options

The Seakeeper 1 requires a compatible Multifunction Display (MFD).

A display is required with the installation of a Seakeeper 1 to support the full functionality of the unit through the Seakeeper App in addition to the ConnectBox. The Seakeeper App provides an interface for controlling the Seakeeper 1 or viewing the Settings, Service, Info, and Alarm pages. The Seakeeper ConnectBox can be helm-mounted to provide an additional interface for controlling the Seakeeper 1 but does not replace the need for a Seakeeper-compatible display.

Figure 10 provides a schematic of the display installation:

Connecting to a Compatible MFD

- The Seakeeper 1 can be connected to a variety of available MFD systems. Refer to the Technical Bulletins Section of the Seakeeper Technical Library for manufacturer specific MFD compatibility technical bulletins.

- MFD specific Technical Bulletins will be updated regularly as new MFD systems become compatible. Currently Garmin, Raymarine, NAVICO, and Furuno offer compatible MFD models.

- Once a compatible MFD has been selected, refer to the appropriate manufacturer specific Technical Bulletin for integration instructions.

- Connect Seakeeper-supplied Ethernet Adapter Cable, D-Code 10 m cable to MFD manufacturer-specific Ethernet adapter cable. Custom Ethernet cables for specific MFD manufacturers are available through Seakeeper and must be purchased with the Seakeeper 1 if connecting to an MFD.

NMEA 2000 Network Connection

The Seakeeper 1 requires a connection to the vessel’s NMEA 2000 network backbone. The Seakeeper 1 will monitor information on the NMEA network to support and optimize the performance of the Seakeeper 1.

- Connect Seakeeper-supplied NMEA Drop Cable to the customer-supplied NMEA 2000 Tee Adapter on vessel’s NMEA 2000 backbone.

- An active NMEA 2000 compatible GPS signal is required on the vessel’s NMEA 2000 backbone to operate the Seakeeper 1.

- If no GPS signal is detected, a warning will be present on the Seakeeper App.

- An active NMEA 2000 compatible GPS signal is required on the vessel’s NMEA 2000 backbone to operate the Seakeeper 1.

ConnectBox Helm Mounting – Optional

- Remote ConnectBox mounting requires Seakeeper part number 90558, ConnectBox Remote Mount Kit.

- Console space required: Approx. 3.41 L x 4.15 W in. (87 x 106 mm).

- Mounting Instructions, Surface Mount: See Drawing No. 90558 – Seakeeper 1 ConnectBox Helm Mounting Kit, for details. Seakeeper ConnectBox 3D Model available upon request.

- Mount ConnectBox Replacement Blank Insert (P/N 12206) into Seakeeper 1 enclosure at the original location of the ConnectBox.