Seakeeper 9 Installation Manual (90222-12); S/N 9-254-5731 to Current

4.0 Cooling Installation

4.1 Cooling Installation Introduction

Reference Documents & Drawings:

90257 – Seakeeper 9 Cable Block Diagram

90251 – Seakeeper 9 Cooling Water Schematic

30331 – Seakeeper DC Seawater Pump Assembly

TB-90947 – Seawater Plumbing Best Practices

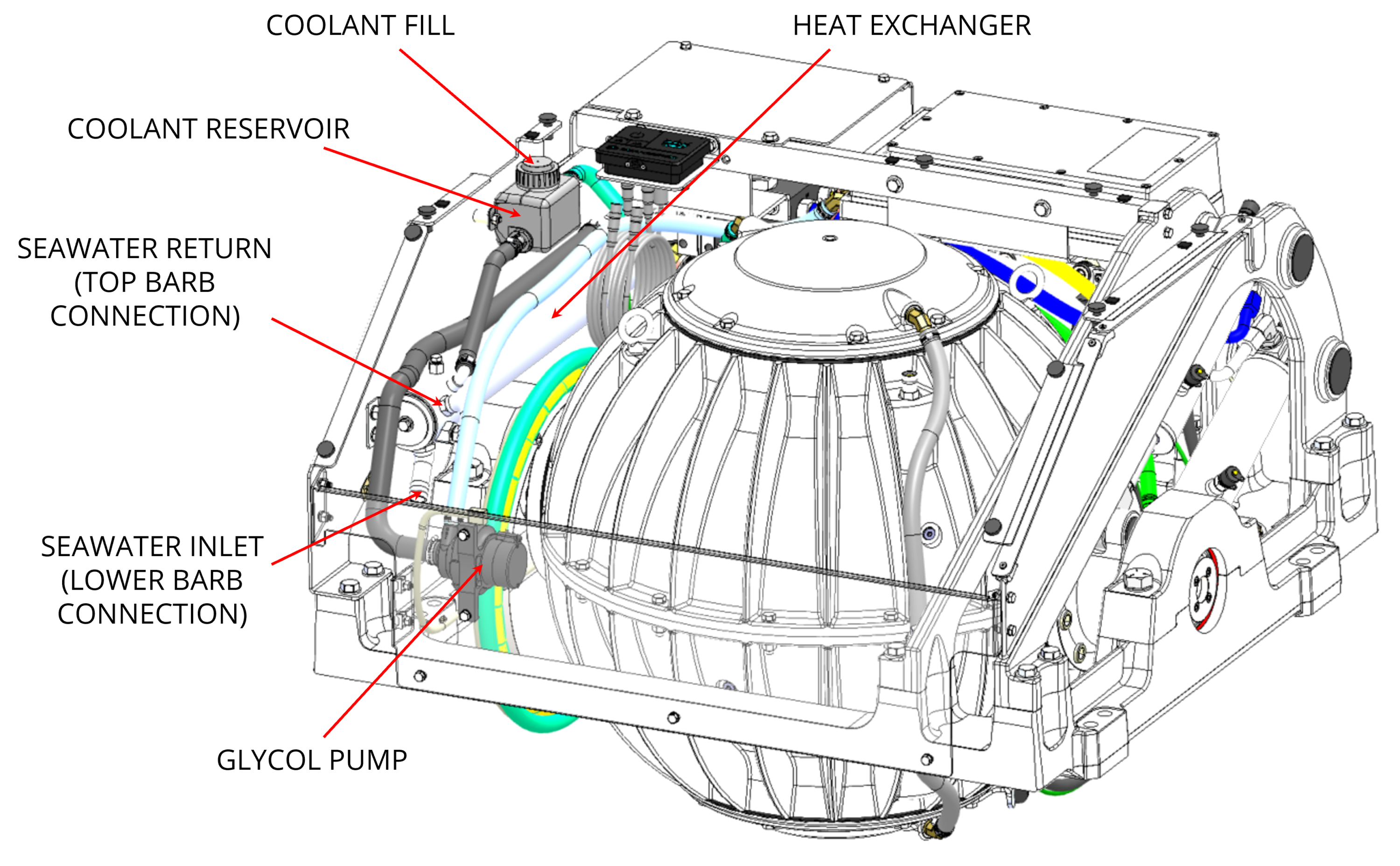

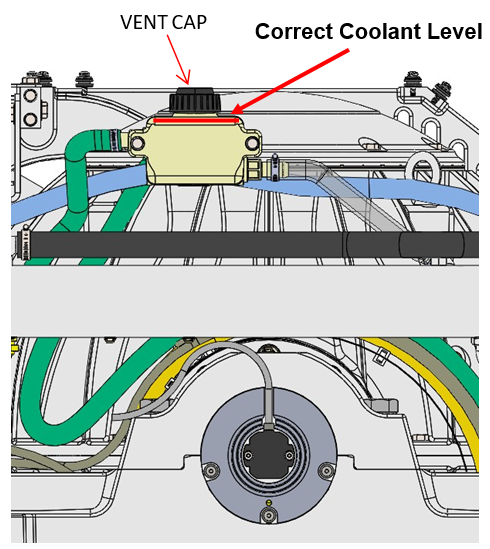

The Seakeeper 9 is shipped with the cooling circuit filled and ready for use (See Figure 40). The Seakeeper 9 requires connection to a raw water pump, referred to as the seawater pump, to cool the closed loop cooling circuit on the unit. The required seawater flow through the Seakeeper 9 heat exchanger is between 4 – 8 GPM (15.1 – 30.3 LPM) when the on-demand cooling system requires cooling. Prior to operation, confirmation of glycol level is recommended.

Seakeeper offers a compatible self-priming DC Seawater Pump (P/N 30331) prewired for the Seakeeper 9 Installation and covered under the standard Seakeeper warranty. The pump conforms to the seawater plumbing best practices noted in TB-90947. See Drawing No. 30331, SeaFlo® Seawater Pump Assembly, and the Seakeeper Options and Accessories Price List for details.

4.2 Cooling System Considerations

- The installer is responsible for supplying a dedicated positive-displacement seawater pump (or electric isolation valve and centrifugal pump) and associated plumbing. Seawater connections on the Seakeeper heat exchanger mate with ¾ in. (19 mm) hose. An optional seawater pump can be purchased through Seakeeper, P/N 30331.

- Unintended seawater flow from the seawater pick-up during underway operations is unacceptable and may cause stress on internal components. Unintended flow should be mitigated through an inlet electric ball valve. Continuous cooling flow from shared through-hull plumbing, a centralized chiller, or a cooling system is unacceptable for Seakeeper models.

- There is no need to disconnect the hose from the glycol pump except to replace the pump. In this case, provision will need to be made to catch the draining glycol, as the plumbing is disconnected. Use caution to avoid breaking plastic hose connections on the pump casing.

- The seawater pump is powered by DC Seawater Pump Output cable on the Seakeeper 9, as outlined in Electrical Installation Section 3.2.

- This pump must operate on 24 VDC, 10 A power. Pumps requiring other voltages or higher current can still be controlled by using this supply to trigger an installer-supplied relay, but a separate source of power must be provided.

- A dedicated through-hull fitting should be installed for each Seakeeper to ensure sufficient seawater flow to that unit onboard the vessel.

- It is recommended that the seawater pump is located below the waterline, as close to the vessel’s baseline as practically possible, to maintain positive inlet pressure on the pump in all operating conditions.

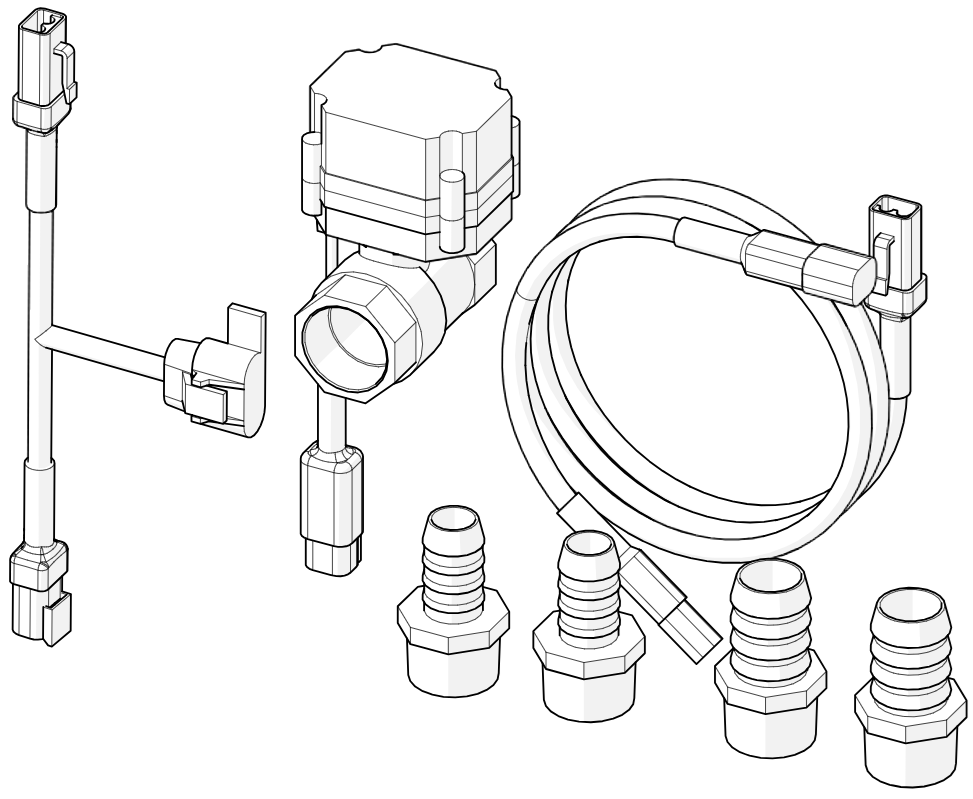

- Install 1 in. electric ball valve (P/N 20762) and two 1 in. to 3/4 in. fittings from kit 90970 shown in Figure 42.

- Install electric ball valve in suction line of pump between the strainer and the seacock valve and within 40 in. (1 m) of seawater pump.

(P/N 90970)

- Seakeeper recommends the seawater pump be located below the waterline, as close to the vessel’s baseline as practically possible, to maintain positive inlet pressure on the pump in all operating conditions.

- A self-priming seawater pump may be required to maintain water flow in all underway conditions. Cavitation can occur at the seawater inlet and potentially cause an air-lock condition restricting seawater flow to the heat exchanger.

- Vented loops are optional and should be considered only with centrifugal-style pumps. Self-priming or positive displacement style pumps do not require a vented loop; this includes Seakeeper P/N 30331.

- Maximum seawater pressure in the heat exchanger is 20 psi (1.4 bar)

- Seawater flow requirement through the heat exchanger is 4 GPM (15.1 LPM) minimum and 8 GPM (30.3 LPM) maximum under all operating conditions of the boat. When sizing the seawater pump, the installer should account for losses in the raw water plumbing. In addition to initial operation at the dock, new Seakeeper installations should be checked to ensure they meet flow requirements while the vessel is at speed. Flows above 8 GPM (30.3 LPM) could shorten heat exchanger life.

4.3 Connecting Seawater to Heat Exchanger

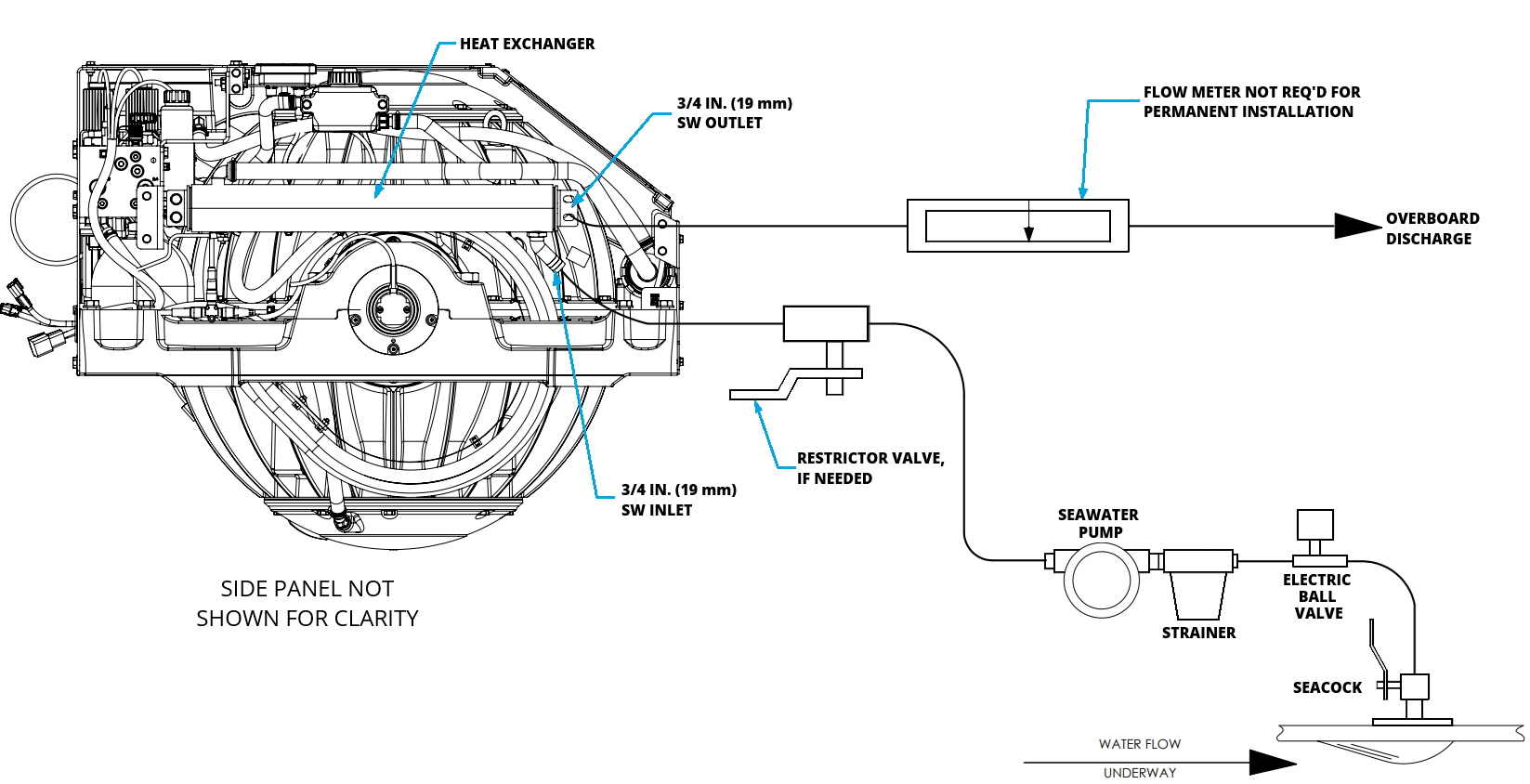

Refer to Figure 43 for typical Seakeeper 9 seawater plumbing arrangement.

- Connect seawater from installer-supplied pump to lower ¾ in. (19 mm) hose barb on heat exchanger per Figure 43. Use the same practices as other below waterline seawater plumbing. Required flow rate is 4 GPM (16 LPM) minimum and 8 GPM (30.3 LPM) maximum.

- Connect seawater discharge (upper hose barb) to overboard drain. (See Figure 43) Use the same practices as other below waterline seawater plumbing.

- In addition to initial operation at dock, new installations should be checked for minimum 4 GPM (16 LPM) flow while vessel is at speed and when backing down. If no other method of confirming flow is available, discharge line may be temporarily diverted to a bucket. Flow is calculated from time to fill a known volume. A self-priming seawater pump (customer/installer supplied) may be required due to installation location to maintain water flow in all underway conditions where cavitation near the intake may occur and potentially cause an air-lock condition restricting seawater flow to the heat exchanger.

- Inspect raw water plumbing after sea trial for any signs of leakage.

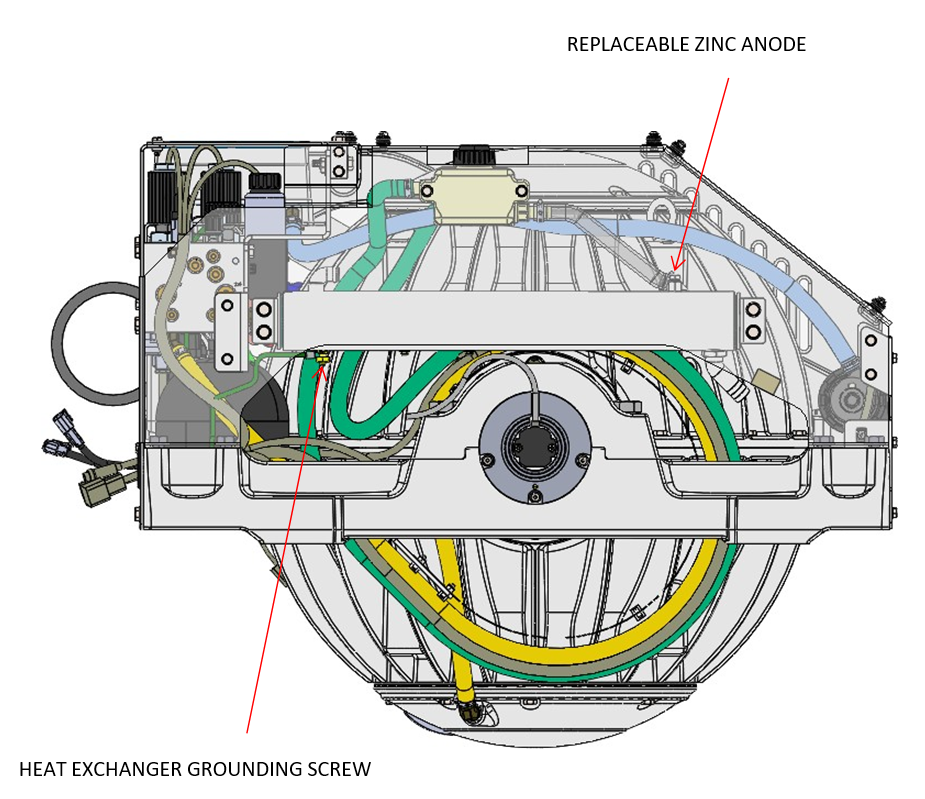

- Heat exchanger contains removable endcaps to provide access for cleaning the tube bundle.

Seakeeper Optional DC Seawater Pump (P/N 30331)

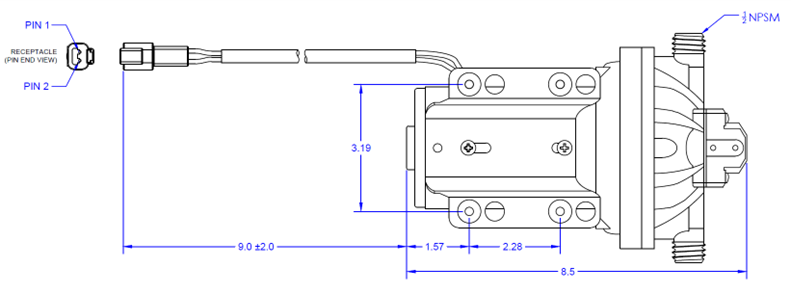

- Seakeeper offers a self-priming DC Seawater pump operated at 24 VDC for the Seakeeper 9 (Figure 44).

- The pump assembly is pre-wired for connection to Seakeeper 9 Seawater Pump Output Cable, “SW Pump Output” and includes a seawater strainer and various fittings. The pump specifications are as follows:

NOTE: Only use SeaFlo®-provided threaded fittings with DC Seawater Pump 30331.

| Volts | 24 VDC |

| Rated Flow | 5.5 GPM (nominal) |

| Overcurrent Protection Rating | 10 A |

| Ignition Protection | ISO 8846 or equivalent |

4.4 Adding Coolant

- Cooling system is filled to proper level when shipped, with a mixture of 50% ethylene glycol and 50% distilled water. The reservoir and clear tube between heat exchanger and reservoir should be filled with green coolant mixture, as shown in Figure 33. If level has dropped, check for evidence of leaks at all connections before adding fluid as described below. If coolant is at the correct level, skip to Section: Connecting Seawater to Heat Exchanger.

- Note: Some amount of entrained air in the fluid is normal and acceptable. This air will be evident by some cloudiness of the fluid. As long as the fluid remains at the specified fill level during operation, the remaining cloudiness is not an issue.

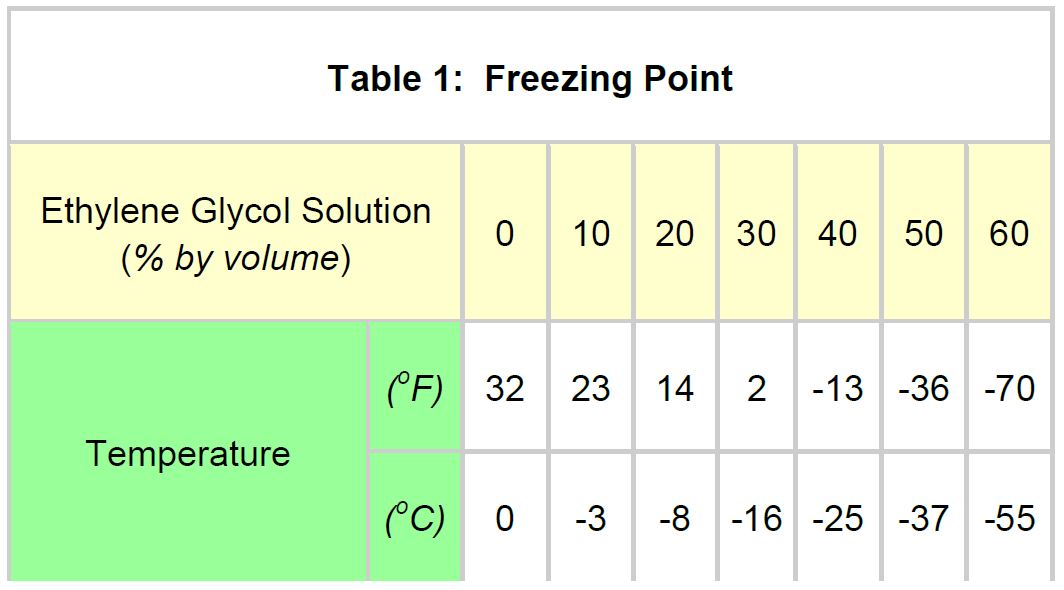

- Mix 50% ethylene glycol with 50% distilled water in a clean container. Refer to Table 1 or glycol manufacturer’s literature for freezing points.

- Remove vent cap on top of reservoir. Pour mixture in until level reaches above inlet of reservoir as shown in Figure 45. Filling reservoir above this level will not cause any damage but coolant may be expelled from vent on top of cap due to normal thermal expansion of coolant.

- Connect 24 V to controller.

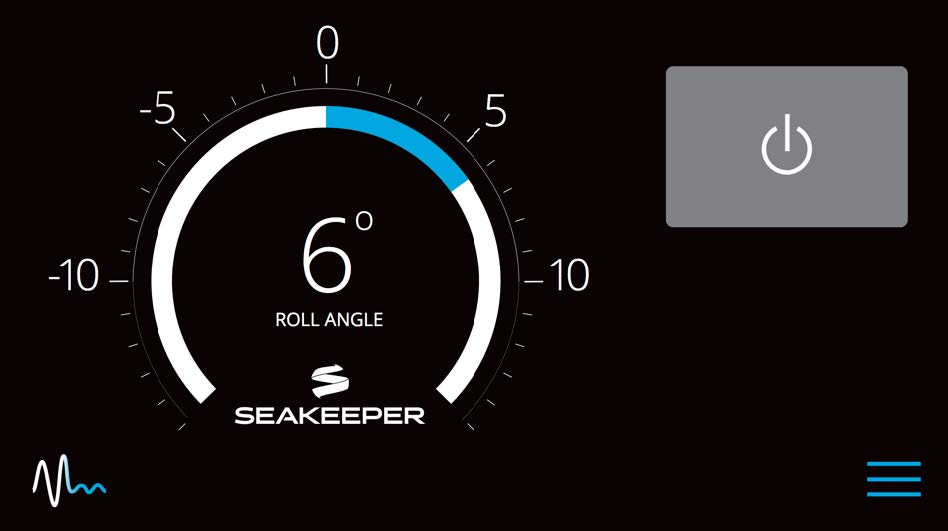

- At the MFD app / optional 5″ Touch Display check for any ALARMS

- Press the POWER ON/OFF button.

- The flywheel will start to spin and the glycol pump will start.

- Recheck glycol level with fluid circulating in coolant circuit. If unable to visually see level, sight down inside reservoir and check that coolant level is above upper port on reservoir as shown in Figure 45.

- After several minutes of running, press POWER ON/OFF button

to turn power off to the flywheel.

to turn power off to the flywheel.

- At the MFD app / optional 5″ Touch Display check for any ALARMS

- The cooling system is self-purging. If small amounts of air are in the system, they will most likely be dislodged during the first sea trial. Re-check glycol level after sea trial and add fluid if required.