Mechanical Installation Manual (750, 750 Quad)

11. Mount Wedge Pack

Mount Wedge Pack Introduction

Care must be taken to ensure clean working conditions. Wearing clean gloves is highly recommended to keep caustic substances off skin and prevent oil and grease from getting on adhesive surfaces.

For concealed cable entry, take note of the Actuator cable routing side. Knowing the routing side will be required when commissioning the system.

11.1 Prepare Parts and Hull

- Wipe the area to be bonded with acetone or denatured alcohol and plain white paper towels.

- Replace the tape around the border of the abraded portion of the transom where the Transom Plate will be mounted. Mask around the mounting location and the bottom of the boat. The tape will help keep the surrounding gelcoat clean of adhesive. The inside of the Cable Gland should be covered to avoid adhesive from entering the gland, particularly when installing with a Concealed Cable Entry as indicated in Section 10.1.

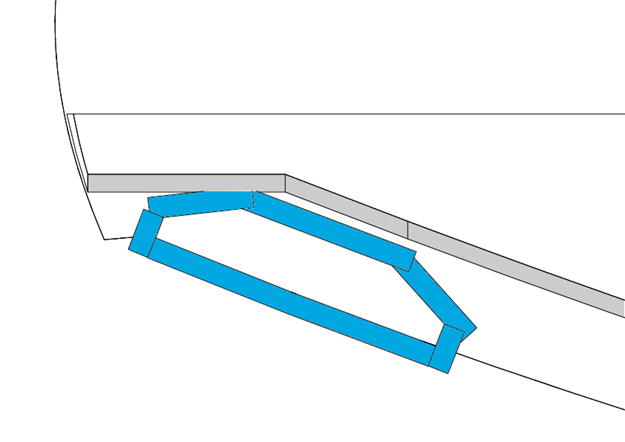

3. Tape the top, side, and bottom edges of the Wedge Pack Assembly. On the bottom, cover the gap between the Transom Plate and the Actuator Plate while leaving the angled portions of the Transom Plate exposed as shown below.

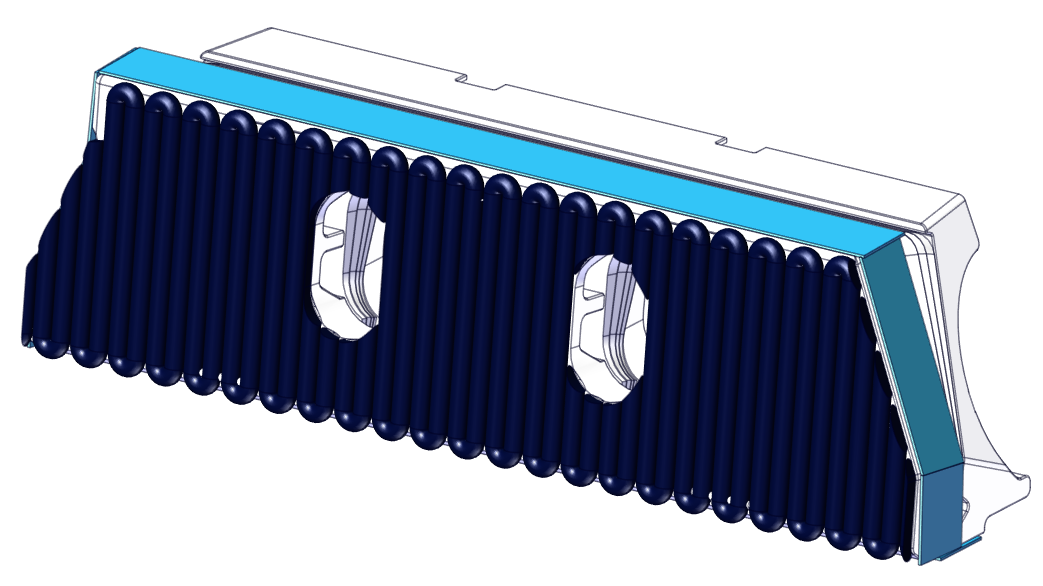

Figure 61 – Tape on Wedge Pack

4. Wipe the mounting face of the Wedge Pack down with denatured alcohol using plain white paper towels to remove oil/surface contaminants. The mounting face will show a matte grey color compared to the gloss black finish of the other parts in the kit. The mounting face has been masked off during the coating process to reduce assembly time.

Please note these solvents will distort the aesthetic quality of the gloss black parts if they spill. Careful application to the mounting surface should be used.

11.2 Clean Adhered Surfaces

- Wipe the Wedge Pack down with denatured alcohol and plain white paper towels a second time to remove oil and/or surface contaminants. Again, solvents will cause aesthetic damage to the coatings on parts, therefore be careful to only apply the wipe on the surface which is mounted to the boat transom.

- Clean the transom mounting location with acetone or denatured alcohol and plain white paper towels a second time to remove oil and/or surface contaminants after sanding.

11.3 Adhere Wedge Pack

- Apply adhesive to both the Transom Plate and transom. Use at least the amount of adhesive listed in the table below to ensure both surfaces are covered completely by adhesive. There must be enough adhesive between the Transom Plate and the transom for a strong bond with no voids. The Transom Plate has three (3) stand offs to allow for adequate adhesive thickness once mounted.

Please verify the adhesive selected from the approved list is compatible with your hull material. If in doubt, contact the adhesive manufacturer for best practice instructions with your given hull material. Some materials may require a primer for best adhesion. See here 3. Tools Needed – Seakeeper Manuals

Note: Work from this point on should be deliberate, keeping in mind the working time of the adhesive being applied. Warmer temperatures reduce working time.

Quantity:

| Controller Size | Minimum Adhesive Quantity (per boat) | Minimum Adhesive Quantity (per Controller) |

| 750 mm Quad | 1500 ml | 750 ml |

| 750 mm Dual | 1500 ml | 375 ml |

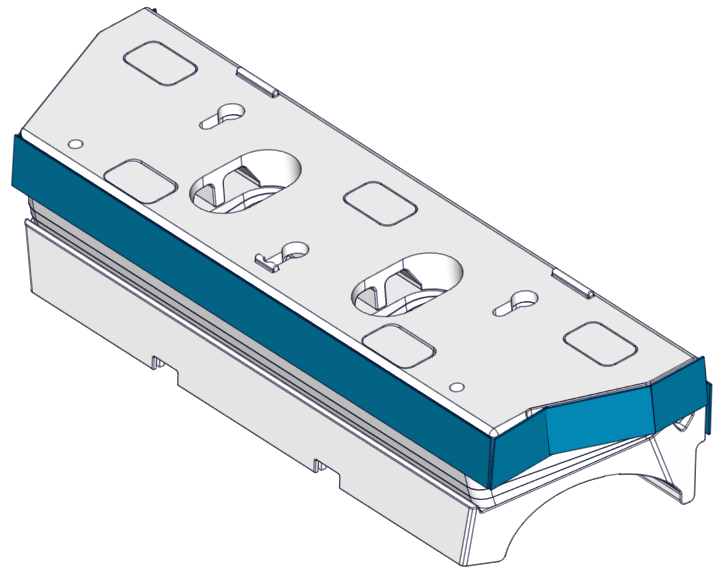

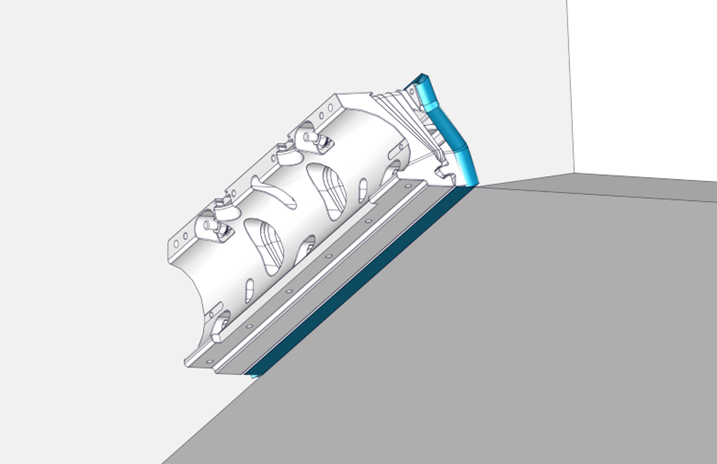

Figure 62 – Adhesive on Wedge Pack and Transom

2. . Install the Wedge Pack Assembly by sliding the keyholes over the positioning screws. Excess adhesive should appear around the entire perimeter of the Wedge Pack Assembly as the Wedge Pack is pressed into place.

11.4 Confirm Location

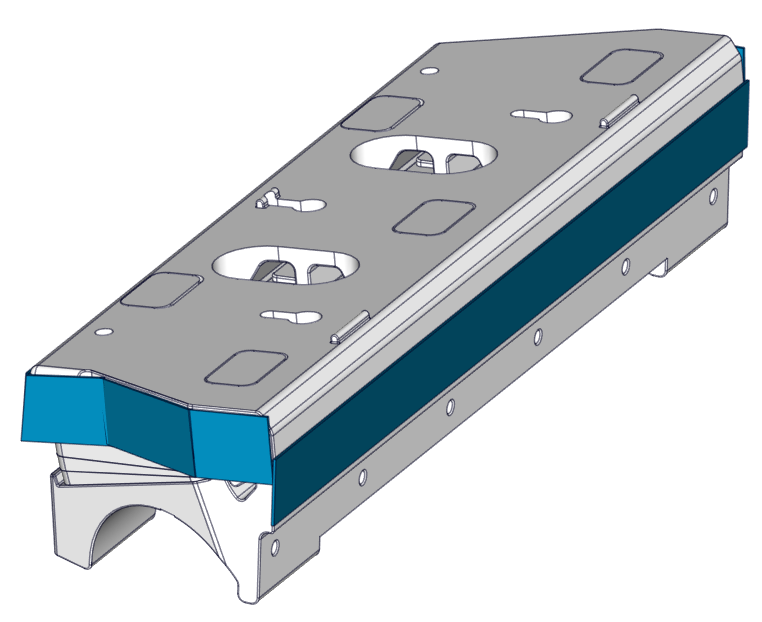

- Add the Seal Plate to the assembly to check its position as indicated in Section 9.

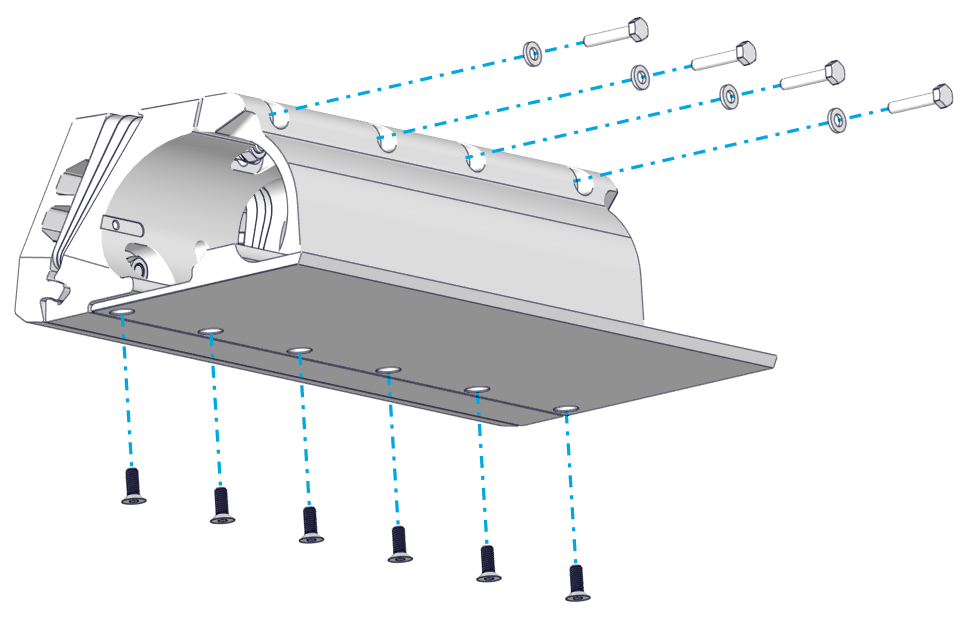

- Thread in the bottom six (6) M6-1.0 x 16 mm Flathead Screws, but do not tighten.

- Thread in the top four (4) M6-1.0 x 30 mm Hex Head Bolts with M6 Washers to align the Seal Plate with the Wedge Pack Assembly, but do not tighten. There should be a gap between the top of the Seal Plate and the Wedge Pack Assembly.

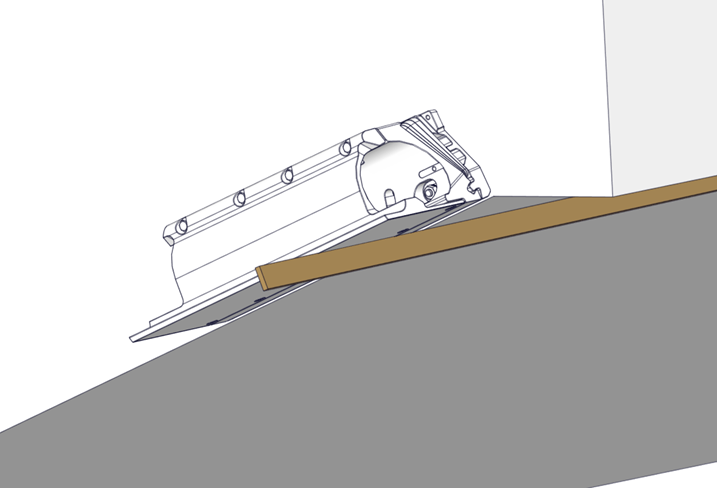

2. Using a straight edge, verify the Wedge Pack is flush with the hull bottom in the desired location as determined in Section 5. Be sure location requirements previously called out are met. Due to different hull shapes and features, the Seal Plate may not be flush with the hull bottom across its full span.

3. Once the position is confirmed, remove the Seal Plate, and tighten the positioning screws with a Phillips head screwdriver. The screws must be tight enough to press out excess adhesive and keep the assembly from sagging.

Note: In the uncommon case that the measured transom angles for the inboard and outboard sides of a Controller location (found in Section 6.1) are greater than 2 degrees apart, tighten beginning on the side with the larger transom angle pulling it tight to the transom. On the side with the smaller transom angle, gently advance the screws but do not tighten it all the way to the transom. If the screws on the side of the smaller transom angle are overtightened, it can stress the fasteners and cause issues.

11.5 Fair in Excess Glue

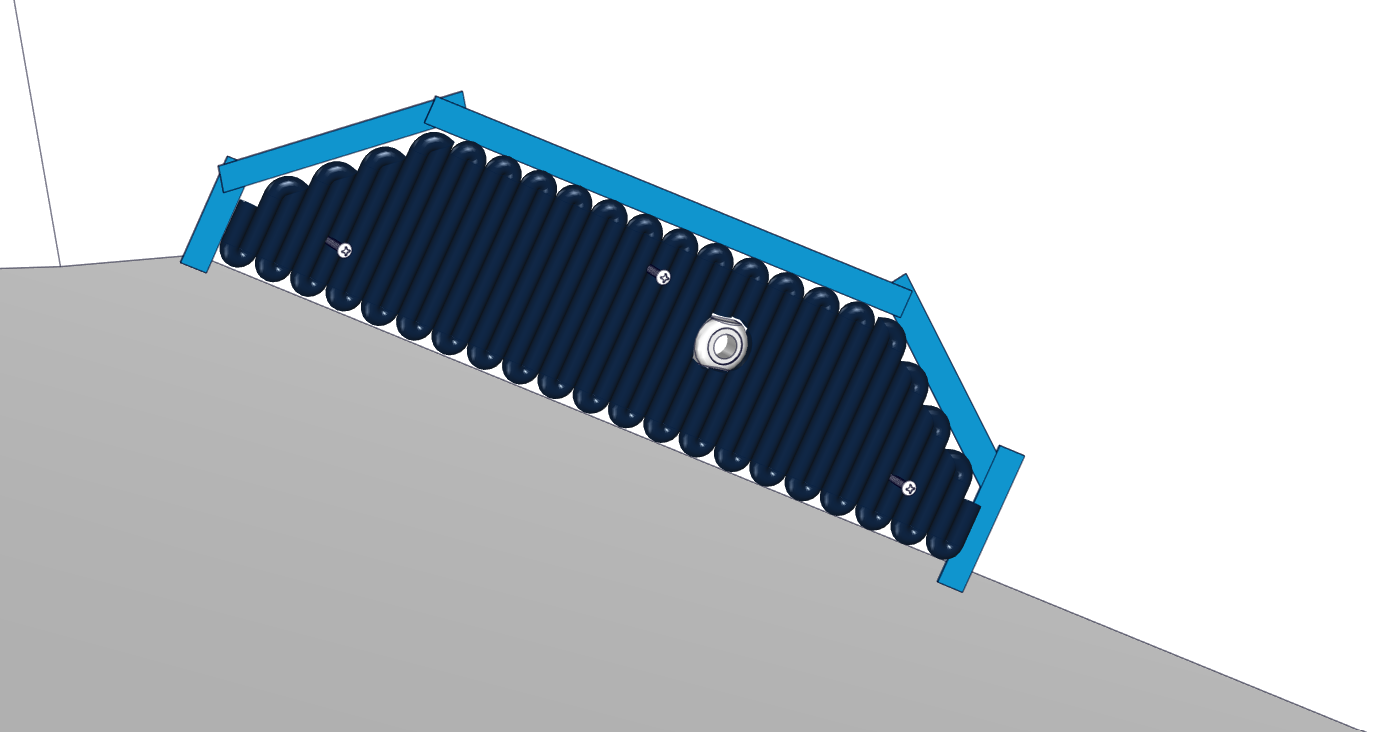

- Using a squeegee, putty knife, or tongue depressor, fill in the gap between the running surface of the hull and the Actuator Plate with excess adhesive, as shown below. Apply extra adhesive as needed. Note: The smooth transition from the hull bottom to the Seal Plate is critical for achieving the best performance out of the system.

2. Using a squeegee, putty knife, or tongue depressor, clean away excess adhesive.

ATTENTION: For concealed cable entry, clean out all of the adhesive from around the Cable Gland. You must make sure the Cable Gland will be accessible after the adhesive cures.

3. Make a smooth transition with adhesive on the upper edges of the Transom Plate to the transom. Apply extra adhesive as needed.

4. Remove the masking tape from the Wedge Pack Assembly and transom. If needed, clean any excess adhesive using denatured alcohol and plain white paper towels.

6. Allow adhesive to cure before proceeding. Some adhesives have ‘handling times’ where the product feels firm but is not ready for loading. Some adhesives also have required times before submersion. Please follow the adhesive manufacturer’s instructions.

7. For aluminum hulls, upon completion of the installation use a paint or similar coatings to protect the edges of aluminum from corrosion seeping between the adhesive and aluminum.